Pizza Box Sizes can look straightforward at first glance, but they influence far more than how a pizza fits inside a box. The right size helps protect crust texture, keeps toppings in place, and supports a clean unboxing experience for dine in, takeout, and delivery. For restaurants and food brands, it also affects storage space, shipping volume, and how consistent each order feels to customers.

This guide breaks down the practical meaning of Pizza Box Sizes, how standard options compare, what common materials do well, and how to choose a size that matches your menu and operating style. If you are buying in bulk, managing multiple locations, or planning custom printing, having a clear sizing approach reduces mistakes, saves cost, and improves the customer experience without making packaging more complicated than it needs to be.

Why Pizza Box Size Matters

Choosing the right Pizza Box Sizes affects much more than whether a pizza fits inside the box. Size decisions shape food quality, handling efficiency, and how customers judge the order when they open it. Understanding these impacts helps businesses avoid small packaging choices that lead to bigger operational problems.

- Food protection and presentation

Proper Pizza Box Sizes help keep toppings in place, prevent the lid from pressing on the surface, and reduce movement during transport. This supports a cleaner appearance when the pizza is served or delivered. - Heat retention and moisture control

Box size influences how steam circulates inside the box. A well matched size helps balance warmth and airflow, reducing soggy crusts while keeping the pizza hot enough on arrival. - Operational efficiency

Using consistent Pizza Box Sizes simplifies stacking, storage, and packing during peak hours. It also helps control material use and reduces wasted space in storage and delivery bags. - Cost and inventory control

Oversized boxes increase material and shipping costs, while undersized boxes can lead to damaged food and remakes. The right size supports predictable purchasing and inventory planning. - Customer perception

Customers often judge portion value and quality visually. Pizza Box Sizes that match the pizza closely create a more intentional and professional impression.

When Pizza Box Sizes are chosen with real use conditions in mind, they support food quality, smoother operations, and a more reliable customer experience across dine in, takeout, and delivery.

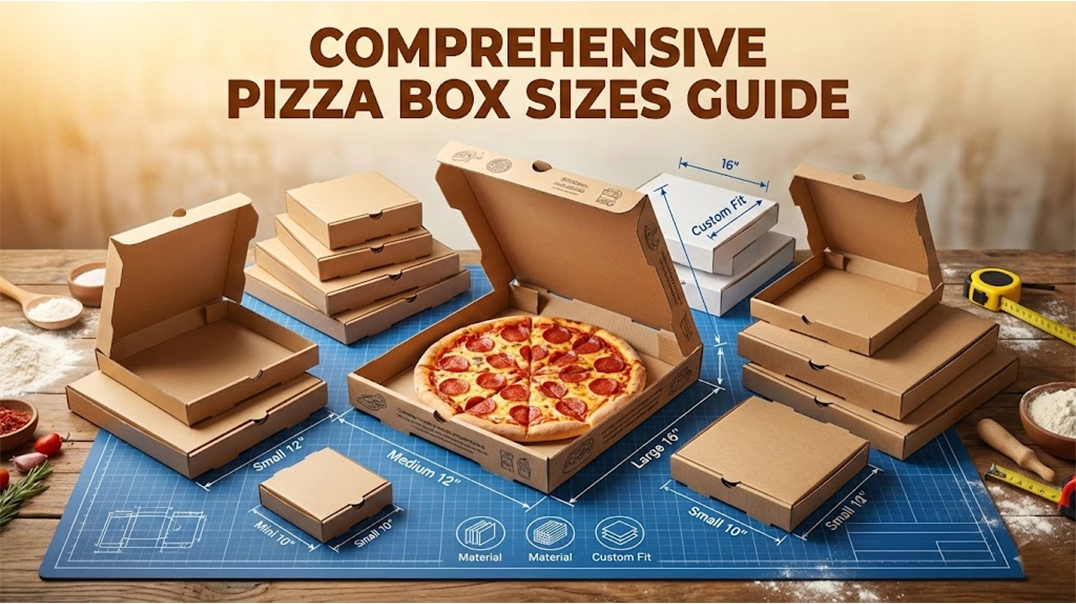

Standard Pizza Box Sizes

In American style pizza service, Standard Pizza Box Sizes are closely tied to common pizza diameters and traditional slicing methods. Boxes are typically made slightly larger than the pizza itself to allow easy loading and limited airflow, which helps manage steam and protect crust texture during delivery.

| American Pizza Category | Typical Pizza Diameter | Common Pizza Box Size (L × W × H) | Typical Slice Count |

|---|---|---|---|

| Personal or Mini | About 6 to 8 inches (15 to 20 cm) | 7″ × 7″ × 2″ or 8″ × 8″ × 2″ square | 4 slices or half cuts |

| Small | About 9 to 11 inches (23 to 28 cm) | 10″ × 10″ × 2″ to 12″ × 12″ × 2″ square | 6 slices |

| Medium | About 12 inches | 13″ × 13″ × 2″ to 14″ × 14″ × 2″ square | 8 slices |

| Large | About 14 to 16 inches | 16″ × 16″ × 2″ to 18″ × 18″ × 2″ square | 8 to 10 slices |

| Extra Large | About 17 to 18 inches | 18″ × 18″ × 2″ to 20″ × 20″ × 2″ square | 10 to 12 slices |

| Jumbo or Party Size | 19 inches and above | 20″ × 20″ × 2″ up to 24″ × 24″ × 2″ square | 12 to 16 slices |

These American focused Standard Pizza Box Sizes reflect mainstream restaurant practice and delivery requirements. While regional variations exist, this sizing structure remains the most widely used reference for American style pizza across dine in, takeout, and delivery operations.

Common Pizza Box Materials

The choice of material directly affects how Pizza Box Sizes perform in daily food service operations, including heat retention, box stability, print quality, and sustainability outcomes. Below are the most commonly used pizza box materials, arranged from mainstream industry use to more specialized applications.

Kraft Paper pizza box

- Visual identity: Kraft paper has a natural brown appearance that aligns with environmentally focused branding and simple, organic design language.

- Structural reliability: When corrugated correctly, kraft paper provides strength comparable to white cardboard and supports a full range of standard Pizza Box Sizes.

- Processing method: As an unbleached material, kraft paper avoids chemical whitening, which reduces environmental impact during production.

- End of life handling: Uncoated kraft pizza boxes offer strong recyclability and are often compostable where facilities are available.

Corrugated Cardboard pizza box

- Structure and strength: Corrugated cardboard contains a fluted inner layer that improves compression resistance, making it suitable for medium to large Pizza Box Sizes that require stacking strength during delivery.

- Heat insulation: The internal air channels slow heat loss while limiting direct moisture contact with the pizza base.

- Ventilation support: This material works well with vent holes that allow steam to escape gradually, helping maintain crust texture.

- Food safety profile: Most food service corrugated boxes are produced using food grade materials, and many suppliers now offer options without intentionally added PFAS.

- Recyclability: Corrugated pizza boxes are widely recyclable in many regions, even with light grease residue, depending on local recycling guidelines.

Sugarcane Fiber pizza box

- Material origin: Sugarcane fiber pizza boxes are made from bagasse, a byproduct of sugar processing that would otherwise be discarded.

- Compostability: These boxes are biodegradable and compostable under appropriate conditions, often without industrial treatment.

- Grease resistance: Natural fiber structure provides effective oil resistance for hot foods.

- Design format: Sugarcane fiber boxes are typically produced as rigid clamshells and are most common in smaller Pizza Box Sizes or slice packaging.

- Sustainability impact: Production does not require tree harvesting and supports circular material use.

White Paperboard pizza box

- Print performance: White paperboard features a smooth, bright surface that supports high quality full color printing, making it suitable for premium branding and retail display.

- Weight and form: This lightweight material is commonly used for smaller Pizza Box Sizes such as personal pizzas, flatbreads, or frozen pizza packaging.

- Moisture sensitivity: Without additional barriers, white paperboard is less tolerant of heat and grease, limiting its use for large hot pizzas.

- Food safety requirements: Certified food grade coatings are essential to ensure safe contact with oily foods.

- Recycling limitations: Clay coated surfaces may complicate recycling processes in some regions.

Summary Table of Pizza Box Materials

| Material | Typical Pizza Box Sizes | Key Strengths | Main Limitations | Sustainability Profile |

|---|---|---|---|---|

| Corrugated Cardboard | Medium to extra large | Strong, insulated, stackable | Bulkier storage | Widely recyclable |

| Kraft Paper | Small to large | Natural look, durable | Limited print contrast | Recyclable and often compostable |

| White Paperboard | Personal and small | Excellent print quality | Lower grease resistance | Recycling varies by region |

| Sugarcane Fiber | Personal and small | Compostable, grease resistant | Limited size formats | Renewable and biodegradable |

Pizza box materials play a critical role in how Pizza Box Sizes perform in real use, influencing strength, heat retention, and food safety. From widely used corrugated cardboard to emerging fiber based options, each material supports different size ranges and service needs. Choosing the right material helps balance functionality, branding, and sustainability without compromising the customer experience.

Regional Differences in Pizza Box Sizes Worldwide

Although terms like small, medium, and large are widely used, Pizza Box Sizes vary significantly across regions due to local eating habits, portion expectations, and serving styles. A size that feels standard in one country may be considered oversized or undersized elsewhere, which directly affects how pizza boxes are designed and used.

Below is a comparison of common pizza diameters and serving norms in major markets, highlighting how regional preferences shape Pizza Box Sizes.

| Region | Common Pizza Diameters | Serving Characteristics |

|---|---|---|

| United States | Personal ~9-10″, Medium ~12″, Large ~14″, Extra Large 16″+ | Pizzas are commonly shared. Large pizzas are usually cut into 8 slices, with extra large and party pizzas designed for group orders. |

| Italy | Typically one size around 10-12 inches (25-30 cm) | Pizzas are usually individual portions served uncut. Sharing sizes are uncommon, though some offer long pizzas for groups. |

| United Kingdom | Small ~9-10″, Medium ~11-12″, Large ~13-14″ | Sizes are slightly smaller than U.S. standards. Many chains also offer a personal size (~7″) and a party size (~15-16″). |

| Germany | Standard ~12″ (30 cm), Large ~14-15″ | Traditional pizzerias offer one main size. American style chains provide multiple options similar to U.S./U.K. sizing. |

| Canada | Medium ~12″, Large ~14″, Extra Large ~16″ | Closely aligned with U.S. sizing. Metric measurements are commonly referenced alongside inches in practice. |

| Japan | Medium ~10-11″, Large ~13-14″ | Sizes are generally smaller than Western standards. Often cut into more slices (10-12) to support group sharing. |

These variations mean that a medium pizza in one country may be labeled as a large in another. In markets like Italy, the concept of multiple pizza sizes is less emphasized, while in North America, Pizza Box Sizes are built around sharing and delivery efficiency. In contrast, Japan reflects smaller average sizes influenced by pricing, dining culture, and group dining patterns.

For businesses operating across regions or serving international customers, understanding these differences is essential. Pizza Box Sizes should be matched to local expectations rather than imported unchanged from another market. A box that fits a U.S. large pizza may feel excessive in Southern Europe, while a European standard box could be too tight for American style pizzas. Adapting box dimensions to regional norms helps ensure consistent food quality, accurate portion perception, and smoother operations across global markets.

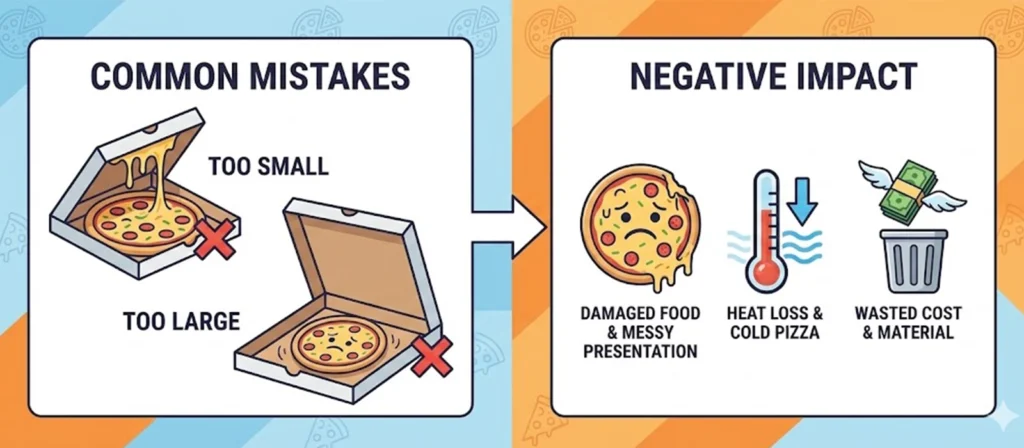

Common Pizza Box Size Mistakes and Their Impact

Even when Pizza Box Sizes appear standard, small sizing decisions can create avoidable problems in daily operations. Many issues only become visible after food leaves the kitchen, affecting quality, cost, and customer satisfaction. The following mistakes are among the most common and have a direct impact on performance.

1. Choosing a Box That Is Too Small

- Causes the lid to press against toppings, leading to cheese sticking and surface damage

- Increases internal moisture, which can soften the crust and reduce texture quality

- Creates a poor first impression when the box is opened

2. Using an Oversized Box

- Allows the pizza to move inside the box during transport

- Speeds up heat loss, especially during longer delivery routes

- Increases material usage and packaging costs unnecessarily

3. Ignoring Box Height and Pizza Thickness

- Fails to account for thick crusts, deep dish styles, or heavy toppings

- Results in compression even when length and width seem adequate

- Reduces consistency across menu items using the same Pizza Box Sizes

4. Overlooking Ventilation Needs

- Traps steam and moisture inside the box

- Makes larger Pizza Box Sizes perform poorly over time

- Undermines crust quality by the time the pizza reaches the customer

5. Mismatching Box Size With Delivery and Stacking Conditions

- Leads to box deformation when stacked in delivery bags or vehicles

- Increases the risk of crushed boxes during busy service periods

- Slows down packing and handling efficiency

Addressing these mistakes helps Pizza Box Sizes work as intended, protecting food quality while improving operational reliability and customer experience.

How to Choose the Right Pizza Box Size

Selecting the correct packaging is a strategic operational decision. Restaurant owners should evaluate these specific factors to ensure Pizza Box Sizes support food quality and kitchen efficiency.

The right size is a balance between product fit, logistical constraints, and cost efficiency. Correct sizing protects the food structure, keeps it warm, and presents the best value to the customer without wasting materials.

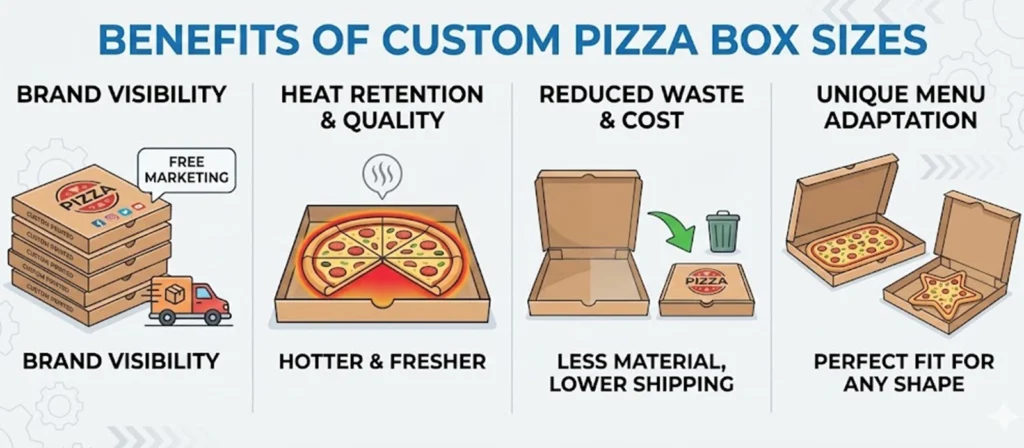

Benefits of Custom Pizza Box Sizes

While standard stock options serve a basic purpose, opting for custom manufacturing allows a business to align packaging strictly with its operational goals. Customization goes beyond just printing a logo; it involves engineering the physical dimensions of the box to solve specific problems related to food quality, marketing, and cost control.

1. Maximizing Brand Visibility and Professionalism

Custom Pizza Box Sizes act as a mobile billboard that travels from the kitchen to the customer’s doorstep. When a box is tailored to the specific dimensions of the pizza, it communicates intentionality and care. Unlike generic boxes that can look sloppy if the pizza swims inside them, a fitted custom box creates a polished presentation that reinforces brand identity. This visual consistency encourages customers to share photos on social media, effectively turning the packaging into a free marketing tool that reaches potential new diners.

2. Optimizing Heat Retention and Food Integrity

Standard boxes are designed for general use, often resulting in excess air pockets that accelerate cooling. Customizing Pizza Box Sizes allows for precise engineering of the internal volume, ensuring the thermal environment is optimized for the specific dough and topping style. A tighter fit significantly reduces movement during transit, preventing the cheese from sliding off and the crust from losing its texture. This technical advantage directly translates to fewer customer complaints about cold or damaged food.

3. Reducing Material Waste and Shipping Expenses

Using a stock box that is even one inch too large for the product results in paying for unnecessary corrugated board and shipping air. Custom Pizza Box Sizes eliminate this waste by using the exact amount of material needed for the menu. Over thousands of orders, shaving a small percentage off the material consumption per unit can lead to significant savings. Furthermore, optimized dimensions can allow for more efficient stacking on pallets and inside delivery vehicles, reducing overall logistics costs.

4. Adapting to Unique Menu Items

Many modern pizzerias are differentiating themselves with non traditional shapes, such as rectangular “meter” pizzas, giant slices, or star shaped crusts. Standard square boxes simply cannot accommodate these items effectively. Developing custom Pizza Box Sizes gives the kitchen the freedom to innovate with the menu without being restricted by the limitations of stock packaging. It ensures that even the most unique culinary creations are supported, protected, and presented exactly as the chef intended.

5. Improving Operational Workflow

Custom boxes can be designed to fit perfectly into specific kitchen shelving, warming cabinets, or delivery bags used by the fleet. Standard sizes often force operations to adapt to the box, whereas custom Pizza Box Sizes are adapted to the operation. This seamless integration speeds up the packing process during peak hours and reduces the friction of handling packaging that is not quite right for the workspace.

Summary of Customization Benefits

| Key Benefit | Impact on Business |

| Brand Presentation | Tailored dimensions create a polished professional look that encourages social media sharing |

| Food Quality | Optimized fit reduces heat loss and prevents toppings from sliding during delivery |

| Cost Efficiency | Eliminates excess material costs and improves shipping density for bulk Pizza Box Sizes orders |

| Menu Flexibility | Supports unique menu items like rectangular pizzas or giant slices that standard boxes cannot fit |

| Operational Flow | Custom dimensions integrate seamlessly with existing kitchen shelving and heating bags |

Conclusion

Great pizza deserves a home that protects it. After spending hours perfecting dough fermentation and sourcing the freshest toppings, the last thing any chef wants is for that hard work to be undone during the final twenty minutes of delivery. Finding the ideal Pizza Box Sizes isn’t just a logistical checkbox—it is the deciding factor between a soggy, lukewarm disappointment and a meal that tastes exactly as it did leaving the oven.

Take a hard look at your current packaging stack. Does it truly serve your menu, or is it merely “good enough”? Whether you stick with reliable standard dimensions or invest in a custom fit that screams your brand identity, the goal remains the same: delivering consistency. When the packaging works invisibly in the background to keep the crust crisp and the cheese intact, you aren’t just selling food; you are delivering a promise of quality that keeps customers coming back for another slice.