The Food and Drug Administration (FDA) is a U.S. federal agency responsible for protecting public health.

In the context of food packaging, the FDA’s role is to ensure that materials in contact with food do not pose safety risks. Any substance that may interact with food must meet FDA safety requirements before it can be legally used in the U.S. market. This regulatory framework is central to FDA regulations and compliance for ensuring safe and legal food packaging.

This article provides a structured overview of how FDA regulation applies to food packaging. It explains the FDA’s authority and scope, defines what qualifies as a food contact substance, outlines the primary compliance pathways, and clarifies labeling obligations that apply to packaged foods. Together, these elements form the foundation for understanding how food packaging can be safely and legally placed on the U.S. market.

FDA’s Role and Regulatory Scope in Packaging Oversight

The FDA’s regulatory authority over food packaging is established under the Federal Food, Drug, and Cosmetic Act (FD&C Act). Section 409 of the Act requires that any substance reasonably expected to become a component of food, or to affect its characteristics, must be authorized by the FDA or determined to be Generally Recognized as Safe (GRAS) for its intended use. This legal framework applies not only to food ingredients, but also to materials used in food packaging and handling.

These requirements are primarily implemented through Title 21 of the Code of Federal Regulations (CFR), Parts 170–199, which define how food contact substances are classified, evaluated, and controlled. The regulations cover both direct and indirect food contact materials, including:

- 21 CFR Parts 174–175: Indirect food additives such as coatings, adhesives, and general packaging components

- 21 CFR Part 176: Paper and paperboard materials, including recycled fiber content

- 21 CFR Part 177: Polymers and plastics intended for food-contact use

- 21 CFR Part 178: Processing aids, adjuvants, and sanitizing agents used during manufacturing

- 21 CFR Part 179: Materials permitted for use in food irradiation processes

In addition to material-specific rules, Parts 170–199 also establish procedural pathways for GRAS determinations, Threshold of Regulation exemptions, and the Food Contact Notification (FCN) program for substances that are newly proposed or not otherwise authorized.

Within this regulatory framework, the FDA’s oversight of food packaging focuses on several key areas:

- Food contact substances (FCSs) used in packaging and handling

- Manufacturing facility standards, including sanitation, process controls, and documentation

- Labeling requirements to ensure accurate and non-misleading safety and usage information

- Import controls for packaging materials and packaged foods entering the United States

For food companies, packaging manufacturers, and exporters, compliance with FDA packaging regulations is a legal obligation directly tied to public health protection. Failure to meet these requirements can result in warning letters, product recalls, detention of goods at the border, import refusals, and long-term reputational damage.

What Food Contact Substances (FCSs) Does the FDA Regulate?

The FDA does not approve or certify food packaging as a complete unit. Instead, it regulates the specific materials that are intended to come into contact with food. These materials are called Food Contact Substances (FCSs) and are evaluated for their potential to transfer chemical components into food under typical conditions of use.

FCSs include a wide range of substances used in the manufacturing and handling of food packaging. Common examples include:

- Plastics and polymers used in containers, films, and caps

- Adhesives that seal multi-layered packaging

- Coatings and linings that prevent grease, moisture, or acid from affecting the food or packaging

- Printing inks and pigments applied to packaging surfaces

- Paper and paperboard, including recycled fibers used in boxes and wrappers

- Processing aids or lubricants that may contact food indirectly during packaging operations

If there is a reasonable expectation that any of these substances could migrate into food, they fall under FDA oversight. The agency assesses each material based on its chemical identity, intended function, exposure level, and safety data. This risk-based approach ensures that food packaging does not become a source of contamination and that all contact materials meet consistent safety standards before entering the U.S. market.

By focusing on individual substances rather than entire packages, the FDA provides manufacturers with flexibility in design while maintaining strict control over what can safely interact with food. This forms the foundation of effective food packaging regulation and long-term consumer protection.

How to Achieve Food Contact Substance Compliance?

To legally market a packaging material that contacts food, manufacturers must demonstrate that each substance involved is safe under its intended use. The FDA provides several regulatory mechanisms to establish this compliance, each suited to different types of substances and exposure levels.

Below are the four primary pathways used to achieve food contact substance compliance in the United States.

1. Food Contact Notification (FCN)

The Food Contact Notification (FCN) program is the FDA’s most streamlined and widely used route for introducing new food contact substances. It applies when a substance is not already authorized under existing regulations and does not qualify for an exemption.

In this process, the manufacturer or supplier submits a comprehensive dossier to the FDA that includes:

- The chemical identity and purity of the substance

- Detailed intended use conditions (e.g. contact type, temperature, duration)

- Results from migration testing, showing the level of substance transfer into food

- Toxicological data to assess consumer exposure risks

- An environmental assessment or claim of categorical exclusion

The FDA reviews whether the use of the substance would result in dietary exposure within safe limits, based on scientific evidence. If no safety concerns are identified, the substance is added to the Inventory of Effective Food Contact Notifications.

Importantly, an approved FCN is:

- Company-specific (only the notifier may use it)

- Use-specific (valid only for the exact conditions submitted)

If another company wishes to use the same substance in a different way, it must submit a new FCN.

2. Food Additive Petition (FAP)

A Food Additive Petition is required when a food contact substance is considered a non-exempt food additive and does not qualify for the FCN program. This is a more rigorous and time-consuming route, typically used for:

- Substances with novel chemistries

- Uses involving higher exposure or unique food types

- Additives with incomplete toxicological profiles

The petition must include extensive scientific data, including:

- Chemical specifications and manufacturing details

- Full toxicology reports

- Dietary exposure estimates

- Migration test results under various food contact conditions

Once the FDA completes its review and determines the substance is safe, it issues a regulation that codifies the additive’s approval in Title 21 of the Code of Federal Regulations (CFR).

Unlike an FCN, a food additive approval:

- Is not company-specific

- May be used by any manufacturer, as long as the use aligns with the regulation’s conditions

3. GRAS (Generally Recognized as Safe)

Some food contact substances may be exempt from premarket approval if they meet the criteria for Generally Recognized as Safe (GRAS). This status applies when qualified experts agree, based on publicly available data, that the substance is safe for its intended use.

There are two routes for GRAS determination:

- Self-determined GRAS: The manufacturer conducts its own safety evaluation and documents the basis for its conclusion. This does not require FDA notification but must be scientifically sound and defensible.

- GRAS Notification to FDA: The company submits its conclusion to the FDA for review. If the agency has no objections, it issues a “no questions” letter, providing added regulatory confidence.

GRAS status is commonly used for well-established substances with a long history of safe use, especially those derived from natural sources or already found in the food supply.

4. Threshold of Regulation (TOR) Exemption

In cases where a substance is used in extremely small amounts and is non-carcinogenic, it may qualify for a Threshold of Regulation (TOR) exemption. This program allows the FDA to exclude the substance from formal food additive regulation if exposure is below a defined dietary threshold.

To apply for a TOR exemption, the manufacturer must submit:

- A quantitative dietary exposure estimate

- Information on chemical identity, intended use, and potential impurities

- Confirmation that the substance is non-genotoxic and non-carcinogenic

- Supporting literature or toxicology data

If the FDA grants the exemption, the substance is listed in the TOR Exemptions Inventory. This pathway is most often used for processing aids, colorants, or minor additives in multilayer packaging.

FDA Food Labeling Requirements

In addition to regulating packaging materials, the FDA also enforces strict requirements for the information presented on food packaging. Labeling plays a critical role in consumer protection by ensuring that buyers receive accurate, consistent, and transparent information about the products they consume.

Under U.S. federal law, most packaged foods sold in interstate commerce must include a set of mandatory labeling elements. These are regulated under 21 CFR Part 101 and must appear prominently on the product packaging. Key requirements include:

- Statement of identity: The legal or commonly accepted name of the food

- Net quantity of contents: The amount of food by weight, volume, or count

- Name and address of the manufacturer, packer, or distributor

- Ingredient list: All ingredients listed in descending order by weight

- Allergen declarations: Mandatory disclosure of major food allergens such as milk, eggs, peanuts, tree nuts, wheat, soy, fish, and crustacean shellfish

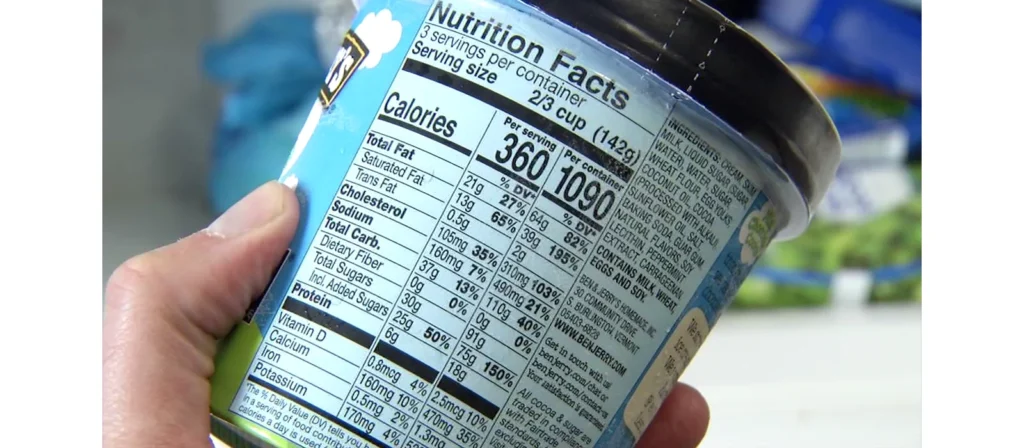

- Nutrition Facts label: Standardized panel showing serving size, calories, and nutrient content based on FDA’s reference values

Beyond content, the FDA also regulates the formatting and placement of labels. This includes requirements for minimum font size, contrast, label location, and language clarity to ensure that information is legible and not misleading.

For imported food products, labels must also meet these same standards. Any non-compliance can result in warning letters, detentions, or refusals of entry at U.S. ports.

Steps to Ensure FDA Compliance for Your Packaging

Ensuring FDA compliance for food packaging requires a structured approach that addresses both material safety and regulatory obligations. Rather than a one-time review, compliance should be treated as an ongoing process integrated into packaging design, sourcing, and labeling decisions.

- Identify applicable FDA regulations

Determine which provisions of the FD&C Act and Title 21 of the Code of Federal Regulations (CFR) apply to your packaging materials and intended use. - Use FDA-authorized materials and substances

Confirm that all food contact materials are authorized under existing FDA regulations or covered by an appropriate pathway such as an FCN, GRAS determination, or Threshold of Regulation exemption. - Assess safety and migration risk

Evaluate whether packaging substances may reasonably migrate into food under normal conditions of use, based on available safety and technical data. - Maintain regulatory documentation

Keep complete and up-to-date compliance records, including declarations of compliance, regulatory citations, and supporting safety information. - Confirm labeling compliance

Ensure that food packaging labels meet FDA requirements for mandatory content, format, and placement. - Implement ongoing compliance controls

Establish internal review procedures to monitor changes in materials, suppliers, or packaging configurations and maintain continued compliance.

By following these steps, companies involved in the manufacture, import, or distribution of packaged food can reduce regulatory risk, avoid compliance disruptions, and support long-term access to the U.S. market.

Conclusion

FDA regulation defines the baseline for whether food packaging can legally enter and remain in the U.S. market. It is not limited to finished packaging formats, but applies to every material that may come into contact with food, every condition of use, and every claim made on the label. Understanding this scope is essential for avoiding compliance gaps that often emerge late in production or at the point of import.

Across the FDA framework, a clear pattern emerges. Food contact safety is evaluated substance by substance, exposure is assessed based on real-world use, and approval pathways are tied to risk level rather than packaging type. Whether compliance is achieved through an FCN, a food additive regulation, GRAS determination, or a threshold exemption, the responsibility remains the same: manufacturers must be able to demonstrate safety with documented evidence.

For companies working with food packaging, FDA compliance should be treated as a structured process, not a one-time regulatory hurdle. Regular material audits, clear compliance pathways, and accurate labeling practices reduce uncertainty and prevent costly disruptions. At Million Pack, we support this process by helping customers select FDA-compliant materials, prepare required documentation, and align packaging designs with applicable regulatory requirements, enabling safer packaging decisions and more reliable access to the U.S. food market.