In the highly competitive world of food service and retail, the integrity of a product is judged the moment a consumer handles its packaging. The corrugated box, often overlooked, is in fact the unsung hero responsible for maintaining thermal integrity, resisting the pressures of stacking, and ensuring the product arrives undamaged. For manufacturers of Food Packaging Boxes, the foundational decision of material choice dictates long term cost efficiencies, logistical performance, and ultimate brand perception, making this a strategic technical choice rather than a simple purchase.

This comprehensive guide is designed to provide packaging engineers, procurement managers, and brand owners with the definitive data needed to make an informed selection. We will break down the structural mechanics, analyze strength comparison metrics, illustrate specific use cases, and provide an essential overview of the global regulatory standards governing food contact materials. By mastering these distinctions, you will confidently choose the optimal material for your specific Food Packaging Boxes and secure both product safety and profitability.

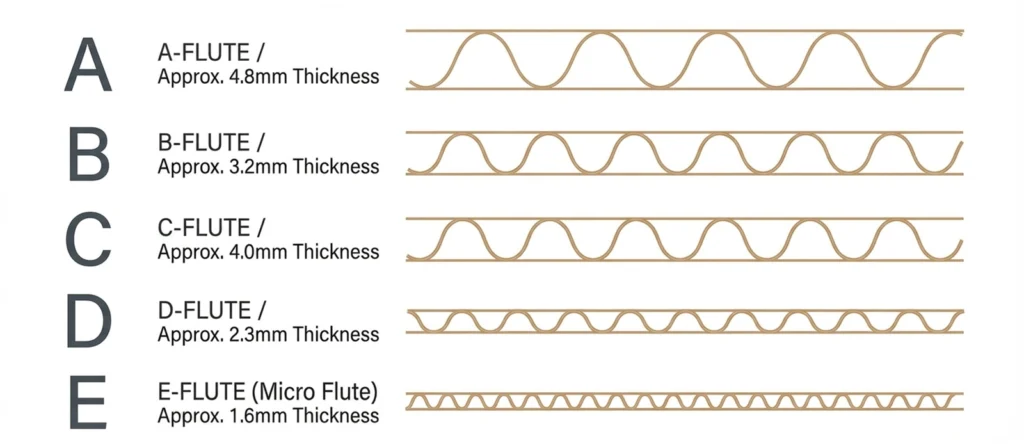

Understanding Flute Types in Cardboard

The term “flute” refers to the undulating medium that is glued between two flat linerboards to form corrugated fiberboard. This wavy structure is the engineering genius of the material, providing both rigidity and cushioning. The air columns trapped within the flutes offer excellent shock absorption and thermal insulation. Flute designations, such as A, B, C, E, and F, categorize the board based on the height and frequency of these waves.

Understanding the precise characteristics of the B and C flutes is the first step toward optimizing your Food Packaging Boxes.

The most common types of cardboard used in single wall applications for food service are B and C flutes, each designed to excel in different performance areas.

B Flute Cardboard: The Sleek Performer

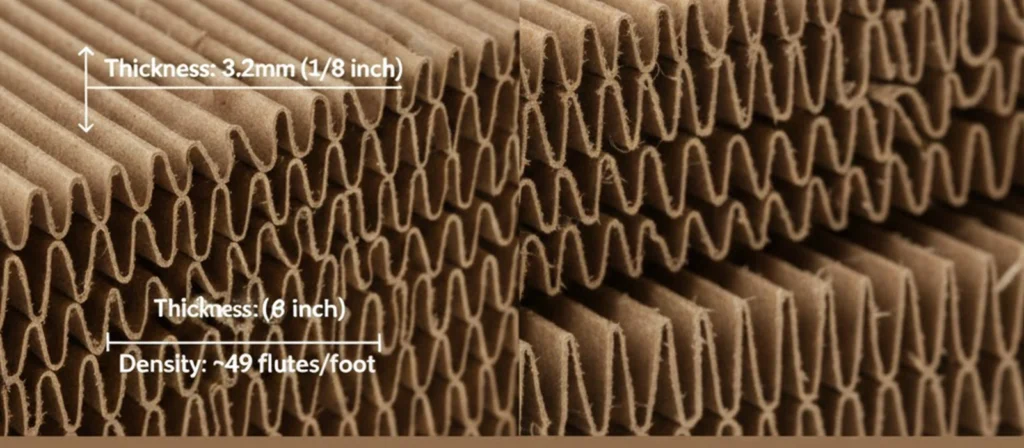

B Flute is characterized by its lower height and higher density of flutes per linear foot.

- Thickness (Caliper): Approximately 1/8 inch (3.2 mm).

- Flutes per Foot (Density): Around 47 to 50 flutes per foot.

- Engineering Focus: High crush resistance, excellent surface printability, and efficient stacking in warehousing.

This compact profile makes B Flute a premium choice where space and appearance are prioritized. Its surface is notably smoother than C Flute, making it ideal for high fidelity direct printing or intricate die cut designs. The consistent, close arrangement of the flutes ensures structural integrity across the board’s surface, lending itself well to automation in packaging machinery. The reduced material bulk also contributes to favorable shipping rates, especially when dealing with large volumes of empty Food Packaging Boxes. It is a frequent choice for products requiring minimal shipping protection but maximum visual quality.

C Flute Cardboard: The Robust Workhorse

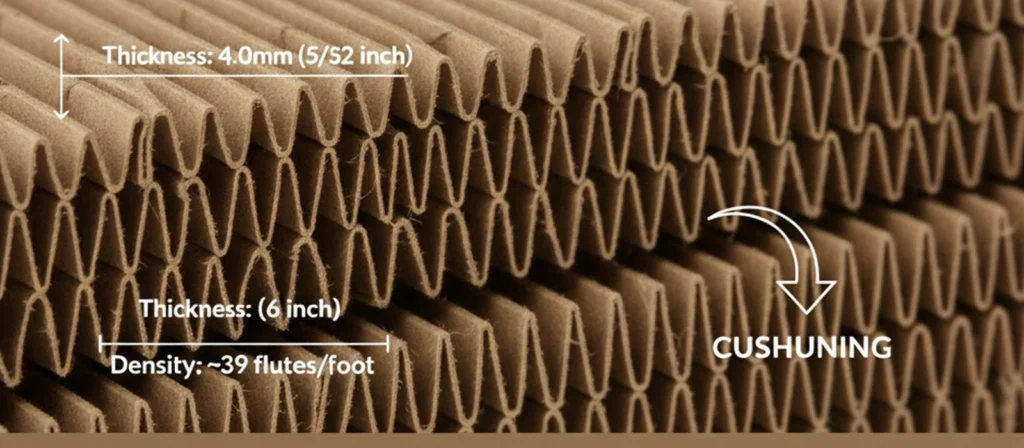

C Flute is the industry standard for general shipping and heavy duty applications, representing a balanced combination of strength and cushioning.

- Thickness (Caliper): Approximately 5/32 inch (4 mm).

- Flutes per Foot (Density): Around 38 to 42 flutes per foot.

- Engineering Focus: Superior stacking strength, better overall cushioning, and greater thermal retention due to the larger air pockets.

C Flute is thicker and contains fewer, but taller, waves. This architecture sacrifices a degree of surface smoothness compared to B Flute but delivers significantly enhanced structural integrity for demanding environments like long haul transport and refrigeration. The taller columns are inherently more resistant to compression in vertical stacks, a key requirement for most wholesale food distribution models. Furthermore, the greater volume of trapped air enhances the cushioning effect, protecting goods from vibrations and minor impacts during handling. It remains the backbone for the large majority of protective Food Packaging Boxes globally.

This foundational knowledge allows us to move into a direct comparison of their critical performance metrics, helping you decide which of these types of cardboard is best suited for your product’s journey.

C Flute vs. B Flute Strength Comparison

The decision between B Flute Vs C Flute for Food Packaging Boxes should be based on quantifiable performance metrics. While both are single wall corrugated materials, their differing flute geometries lead to distinct advantages in compression, burst strength, and overall handling characteristics.

The following table summarizes the key structural differences and performance characteristics:

| Feature | B Flute | C Flute | Performance Implication for Food Packaging |

|---|---|---|---|

| Thickness (Approx.) | 3.2 mm (1/8 inch) | 4.0 mm (5/32 inch) | C Flute offers more thermal mass and void fill; B Flute is more compact. |

| Flutes per Foot | Around 49 | Around 39 | B Flute has a flatter surface, better for high quality printing, minimizing “washboard” effect. |

| Stack Strength (ECT) | Moderate (Typically 32 to 36 ECT) | Strong (Typically 40 to 44 ECT) | C Flute is superior for heavy loads and high stack warehousing environments. |

| Cushioning & Shock | Fair | Better | C Flute’s taller flutes absorb impact more effectively during transit and rough handling. |

| Printability | Excellent | Good | B Flute is ideal for complex, multi color graphics where image clarity is paramount. |

| Space Efficiency | High | Moderate | B Flute reduces storage and shipping volume due to its lower profile, saving logistical costs. |

This comparison clearly illustrates the trade offs involved in selecting types of cardboard. The choice involves balancing the need for visual appeal with the requirement for structural endurance.

In Depth Analysis of Critical Metrics

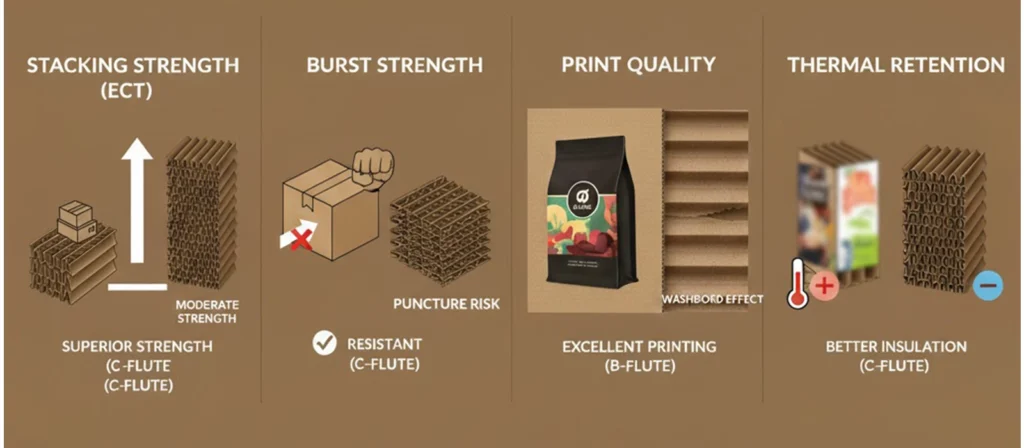

1. Edge Crush Test (ECT) and Stacking Strength

The Edge Crush Test (ECT) measures the maximum compressive force a short column of corrugated board can withstand before buckling. C Flute consistently yields higher ECT values than B Flute of comparable paper weight. This superior stacking strength is a direct result of the taller flute geometry, which acts more effectively as a column supporting vertical load. For food items shipped in bulk or stored on high racks in a cold room, C Flute is indispensable. Using a B Flute box for heavy, stackable produce, for example, risks complete structural failure and subsequent product damage. The inherent rigidity of the C Flute configuration is engineered specifically for demanding, high pressure environments common in warehousing and transport.

2. Burst Strength (Mullen Test)

While less common than ECT for shipping applications, Burst Strength measures the force required to puncture the side of a box. C Flute often demonstrates higher burst strength due to its greater overall caliper and material volume, providing better resistance against tearing or rough handling. This is particularly relevant for packaging sharp or irregularly shaped food items that could puncture the box wall during automated handling or sorting. The additional layer of material thickness in C Flute provides an extra buffer of safety against external impacts.

3. Print Surface Quality

Conversely, B Flute dominates in print quality. The higher density of flutes and the lower flute height mean the outer linerboard has less unsupported area. When the printing plate presses against the board, the low profile of the B Flute prevents the subtle corrugation pattern, known as the “washboard effect,” from showing through the ink. This makes B Flute the definitive choice for premium, shelf ready Food Packaging Boxes where a smooth, high resolution finish is mandatory for brand aesthetics. B Flute provides a near flat canvas for printing sophisticated graphics and detailed product information.

4. Thermal Retention

The larger, sparser air pockets within the C Flute structure provide a slightly superior thermal barrier compared to the dense, shallow air pockets of B Flute. This minor difference becomes significant for hot food delivery, such as pizza or prepared meals, where maximizing heat retention during the final mile of transport is crucial for food quality and safety. The air in the C Flute acts as a more effective insulator, slowing down the temperature loss of the enclosed hot food. This subtle thermal benefit contributes directly to a better customer experience upon receiving the product.

- For Edge Crush Test (ECT) and Stacking Strength, C Flute is better.

- For Burst Strength (Mullen Test), C Flute is better.

- For Print Surface Quality, B Flute is better.

- For Thermal Retention, C Flute is better.

Therefore, the performance data clearly dictates the intended application. C Flute for demanding structural loads and cushioning, and B Flute for excellent presentation and space efficiency.

Best Use Cases: B Flute vs. C Flute Applications

Selecting between B Flute Vs C Flute requires a deep understanding of the product’s lifecycle, from the packaging line to the customer’s hands. The best material choice is always a function of the item’s weight, shape, temperature, and required shipping environment. These two primary types of cardboard serve distinct, yet equally important, roles in the vast ecosystem of Food Packaging Boxes.

When to Choose C Flute (Transport & Protection)

C Flute is the undisputed champion when the primary concern is the physical protection of the contents during transit and storage. Its increased thickness and superior compressive strength make it the go to material for heavy, moisture sensitive, or bulk applications.

- Pizza Delivery Boxes: The classic application for C Flute. The taller air columns provide crucial insulation, helping to keep the pizza warm during delivery. More importantly, its superior stacking strength prevents the top box from collapsing under its own weight or the weight of subsequent boxes, which is a common failure point when hot, steaming food weakens the cardboard fibers. The robust structure helps maintain the original shape of the box throughout the delivery route.

- Bulk Produce Transportation: For items like apples, potatoes, or bottled beverages, C Flute is essential. These products are often packed into large Food Packaging Boxes that are stacked five or more layers high on a pallet. The high ECT value of the C Flute ensures the bottom boxes can withstand the immense static load without crushing the contents. The added cushioning also protects delicate fruits and vegetables from bruising or damage during road transport and warehousing.

- Cold Chain and Frozen Foods: While specialized coatings are necessary for moisture resistance, the fundamental structure of the C Flute provides an advantage in refrigeration. The thicker paperboard and larger air gaps create a more effective thermal buffer against rapid temperature fluctuations, crucial for maintaining food safety and quality in frozen or refrigerated goods during loading and off loading. This stability is key to preventing freezer burn and maintaining product integrity.

- Shipping Cartons for Primary Packaging: C Flute is commonly used for the outer Food Packaging Boxes that contain smaller, primary retail packages. It serves as the durable, protective layer necessary to move high volumes of product through fulfillment centers and distribution networks, often enduring rough handling by mechanized systems.

When to Choose B Flute (Display & Branding)

B Flute excels in situations where the Food Packaging Boxes need to be aesthetically pleasing, cost effective to ship, and require precise folding and sealing. Its thinner profile and excellent print surface lend themselves to consumer facing retail applications.

- Custom Printed Retail Boxes: If a food item is destined for a supermarket shelf or a consumer facing retail environment, the Food Packaging Boxes become a key marketing tool. B Flute’s smooth surface is perfect for litho lamination and direct flexographic printing, allowing brands to showcase vibrant colors, high resolution images, and intricate text without the distracting “washboard effect.” Examples include high end gourmet snack boxes or specialty coffee packaging, where the unboxing experience is part of the brand.

- Lightweight Takeaway Containers: Many single serve takeaway items, such as pastry boxes, burger cartons, or smaller meal kits, use B Flute. Its low profile allows for tighter, cleaner creases during the die cutting and folding process. This results in a structurally sound yet aesthetically sharp box that is pleasant for the consumer to handle and use. The compactness also means less material cost and reduced storage footprint for the food service provider’s busy kitchen or storage area.

- Internal Fitments and Pads: Due to its lower thickness, B Flute is frequently employed inside larger C Flute or double wall boxes as internal dividers, pads, or protective sleeves. It provides necessary separation and minor cushioning without occupying excessive void space, optimizing the overall packaging dimensions and minimizing excess air shipping costs. This efficient use of space is crucial for minimizing costs in large scale operations.

- E Commerce Meal Kits: For meal kits where the contents are lightweight and pre packaged, B Flute is often chosen to reduce the overall shipping weight and dimensional size, leading to significant savings in high volume e commerce fulfillment operations. The lighter weight directly translates to lower shipping surcharges, making the B Flute an economical choice.

The application dictates the choice. A company shipping heavy, temperature sensitive produce will always rely on the resilience of C Flute, while a brand selling premium artisanal chocolates will prioritize the print quality and presentation of B Flute.

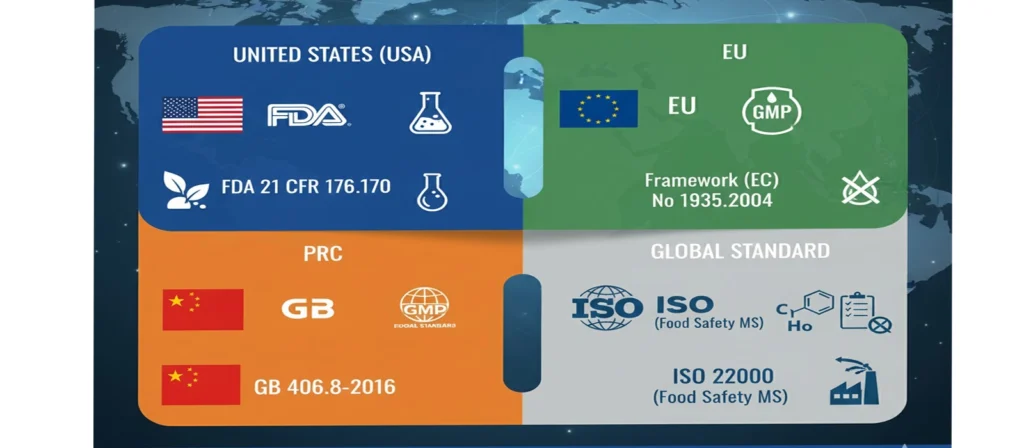

Global Regulatory Standards for Corrugated Food Packaging

The regulatory compliance of Food Packaging Boxes is non negotiable, particularly when using materials like corrugated cardboard which may contain recycled fiber. The primary risk revolves around the migration of non food safe substances, like heavy metals, mineral oils, or inks, from the packaging material into the food. Whether you select B Flute Vs C Flute, compliance with global standards is paramount to market access and consumer trust.

To ensure consumer safety and market access, manufacturers must strictly adhere to the established guidelines in their target markets. The following table details the key regulatory focuses across major global economies, highlighting the specific challenges associated with corrugated types of cardboard:

| Regulatory Jurisdiction | Primary Regulation and Focus | Critical Compliance Focus for Cardboard | Enforcement and Testing |

|---|---|---|---|

| United States (USA) | FDA 21 CFR 176.170 (Components of Paper and Paperboard in Contact with Aqueous and Fatty Foods). | Focus on the Purity of Virgin Fiber and Limited Migration of components from recycled material. Substances like heavy metals and unapproved additives must not migrate into the food above defined limits. | Migration testing under worst case storage conditions (time, temperature, fat or aqueous simulants) is mandatory. The burden of proof for “Generally Recognized as Safe” (GRAS) status for contact components rests with the supplier. |

| European Union (EU) | Framework Regulation (EC) No 1935/2004 (Materials and Articles Intended to Come into Contact with Food) and Good Manufacturing Practice (GMP) Regulation (EC) No 2023/2006. | Mineral Oil Aromatic Hydrocarbons (MOAH) and Mineral Oil Saturated Hydrocarbons (MOSH) are a major focus, especially in recycled cardboard, due to their potential migration from printing inks. | Comprehensive testing for specific substance migration is required, often utilizing C10 to C50 mineral oil analysis. Strict adherence to GMP throughout the entire manufacturing chain, from pulp to final Food Packaging Boxes to control contamination risks. |

| People’s Republic of China (PRC) | GB 4806.8-2016 (National Food Safety Standard, Paper and Paperboard Materials and Products for Food Contact). | Specifies strict maximum limits for Heavy Metals (Lead, Cadmium, Arsenic) and total migration limits for non volatile substances under various test conditions. Covers both virgin and recycled paper, with specific requirements for different food types. | Migration testing using simulant liquids (e.g., water, acetic acid, ethanol) under specified time and temperature protocols relevant to the intended use. Compliance requires supporting test reports from accredited laboratories. |

| Global Standard | ISO 22000 (Food Safety Management System) | While not a mandatory product standard, it guides the process control, demanding comprehensive hazard analysis and critical control points (HACCP) in the production of all types of cardboard for food use. | Certification requires continuous auditing of manufacturing facilities and meticulous documentation of safety procedures, including raw material traceability and storage conditions. This system reinforces confidence in the final Food Packaging Boxes. |

Compliance is not simply about choosing the right flute. It is about the types of cardboard used, specifically the quality and source of the linerboard and the adhesive. For Food Packaging Boxes that are intended for direct food contact, virgin paperboard is often mandated or strongly preferred to mitigate migration risks associated with recycled fiber and its potential contaminants. When recycled materials are used, advanced barrier coatings and rigorous testing are essential to meet these stringent international requirements, ensuring that the structural advantages of B Flute Vs C Flute do not come at the expense of public health. The commitment to these standards must be validated through certificates of conformity and regular material testing, providing absolute assurance to the consumer.

Types of Cardboard Used in Food Industry

In the world of packaging, especially within the food industry, corrugated board plays a vital role. It is more than just a simple “box”; its internal wavy structure, known as the “flute,” determines the board’s strength, cushioning properties, and suitability for various applications. Different flute types vary in height and density, offering a diverse range of solutions from lightweight retail packaging to heavy-duty shipping containers. Selecting the appropriate flute type for a product is a critical step in ensuring that food items remain safe and intact during transportation and storage.

The table below details five common flute types—A, B, C, D, and E—and their characteristics:

| Flute Type | Flutes per Foot | Flute Thickness | Characteristics & Applications |

|---|---|---|---|

| A-Flute | 33 +/- 3 | 3/16″ (4.8mm) | The highest flute type, offering the best cushioning and stacking strength. Commonly used for packaging fragile items like fruit, glassware, and large appliances. |

| B-Flute | 47 +/- 3 | 1/8″ (3.2mm) | With a lower flute height, it provides good crush resistance and a smooth surface for printing. Suitable for inner packaging of food cans, beverages, and various retail goods. |

| C-Flute | 39 +/- 3 | 5/32″ (4.0mm) | Its performance is between A-flute and B-flute, making it the most common and “all-purpose” flute type. Widely used for creating shipping cartons for items like furniture, books, and various foods. |

| D-Flute | 51 +/- 3 | 3/32″ (2.4mm) | A newer flute type that offers a better strength-to-weight ratio than B-flute. Suitable for consumer goods packaging that requires moderate strength in a limited space. |

| E-Flute | 90 +/- 4 | 1/16″ (1.6mm) | Very thin with a smooth surface, providing an excellent substrate for high-quality printing. Ideal for retail display packaging, such as cosmetics, small appliances, and pizza boxes. |

In summary, from the top-tier protection of A-flute to the fine printing surface of E-flute, each type of corrugated board has its unique advantages. Understanding these differences helps food producers and distributors find the optimal balance between product protection, cost-effectiveness, and brand presentation. The right choice not only reduces loss but also builds a professional and reliable impression in the minds of consumers.

Conclusion

The final decision between B Flute Vs C Flute for your Food Packaging Boxes must be a calculated strategic choice, weighing operational costs against consumer safety and brand presentation. For demanding logistical tasks involving heavy stacking, long distance transportation, or crucial thermal insulation, the superior thickness and compressive strength of C Flute make it the definitive material, guaranteeing product protection throughout the supply chain. Conversely, businesses prioritizing retail shelf appeal, high fidelity brand printing, and logistical efficiency for lightweight items will find the sleek, low profile design of B Flute to be the optimal solution, maximizing space savings and visual impact.

Regardless of which of these types of cardboard you select, adherence to strict global regulatory standards is non negotiable. We encourage you to utilize this detailed comparison and consult with packaging specialists to implement a solution that not only meets your performance requirements but also reinforces your commitment to quality and compliance.

FAQs

Q1. What flute is best for pizza boxes?

C Flute is best. Its 4.0 mm thickness and taller flutes provide superior thermal insulation to keep the pizza hot and necessary stacking strength to prevent the box from crushing under its own weight or other boxes, which is essential when the material is weakened by steam.

Q2. What’s the difference between B flute and C flute cardboard?

C Flute is thicker (4.0 mm) with fewer, taller flutes, offering better stacking strength and cushioning. B Flute is thinner (3.2 mm) with more, shorter flutes, providing a smoother surface for high quality printing, better puncture resistance, and higher space efficiency.

Q3. How does the initial cost per box compare for B Flute Vs C Flute?

C Flute is generally slightly more expensive per box due to its taller profile requiring 10 to 15 percent more paper material. However, C Flute’s superior strength can lead to lower total landed costs by reducing damage claims and enabling higher stacking in warehouses.

Q4. Are B flute boxes recyclable and eco-friendly?

Yes, B Flute Food Packaging Boxes are fully recyclable, provided they are not heavily contaminated. B Flute is often considered more eco-friendly because its thinner profile requires less fiber material per box than C Flute, contributing to better sustainability goals.

Q5. How does moisture affect the performance difference between B Flute Vs C Flute?

Moisture weakens both types of cardboard significantly. C Flute, due to its thicker, more robust structure, retains a slightly higher percentage of its original strength compared to B Flute in high humidity environments. For serious moisture resistance, specialized liners and coatings are required for both flute types.