Perforated packaging is designed with small, carefully placed holes or slits to improve airflow, control moisture, and enhance usability, all while maintaining product protection. In eco-friendly foodservice applications, perforation plays an important role in keeping food fresh, particularly in containers like takeaway boxes, salad bowls, and vented cup lids.

In sustainable food packaging, perforation is more than just a design detail. It is a functional element that directly supports food safety, quality, and overall user experience. For example, a compostable box with a vented lid allows steam to escape, helping hot food stay crisp. Perforated wraps or cutlery sleeves offer breathability while maintaining hygiene. Whether integrated into the packaging structure or added as a customization feature, perforation helps improve performance across a wide range of foodservice scenarios.

Why Does Perforated Packaging Matter?

Not everything that matters in food packaging is immediately visible. Sometimes it is the smallest and most overlooked details that influence food quality, the rhythm of a busy kitchen, and even how customers feel when they open their meal. Perforation is one of those details. It is subtle and easy to miss, yet it quietly improves how packaging performs when it counts.

In a fast‑moving foodservice environment, packaging needs to do more than look good. It needs to work. It needs to help maintain freshness, make handling easier, reduce unnecessary materials, and support a smoother overall operation. Perforated packaging achieves these goals in a simple and practical way that fits naturally into daily foodservice routines.

That is why it matters. And here are five reasons that explain its importance.

Preserves Food Freshness

Food that arrives soggy, steamed, or with altered texture can quickly lead to customer complaints. Perforated packaging helps solve this by allowing steam to escape from hot foods, maintaining crispness and preventing condensation buildup. This is especially important for items like fried foods, grilled proteins, or stir-fried dishes. By preserving the intended texture and flavor, perforation helps deliver a consistently satisfying food experience.

Improves Usability for Staff and Customers

Practicality is everything in busy kitchens and on-the-go meals. Perforated designs allow easier opening, tearing, or separation of packaging components, which improves speed and reduces stress for kitchen staff. For customers, simple features like vented cup lids or easy-tear wraps enhance the overall user experience. This small convenience translates into greater efficiency, fewer spills, and a smoother service flow.

Supports Ventilation for Specific Foods

Certain food items require controlled airflow to maintain quality. Fresh salads, baked goods, and some ready-to-eat items benefit from slight ventilation to avoid excess moisture while still staying protected. Perforations enable this micro-ventilation, allowing just enough air exchange to preserve freshness without exposing the product. This thoughtful design adds an extra layer of functionality to eco-friendly food packaging.

Reduces Material Waste and Enhances Sustainability

Perforated packaging supports sustainability in two key ways. First, it can eliminate the need for extra liners, vent holes, or multi-layer materials that increase environmental impact. Second, when combined with compostable or biodegradable materials, perforation enhances the packaging’s overall performance without adding complexity. The result is a smarter, leaner solution that aligns with modern sustainability goals.

Reinforces Brand Quality and Customer Perception

The details matter. When customers notice that their food packaging is functional, well-ventilated, easy to open, and still environmentally friendly, it reflects positively on your brand. Perforated packaging communicates professionalism, care, and innovation—qualities that influence customer trust and loyalty. It shows your brand is not only committed to food quality but also to the environment and the dining experience.

Types of Perforated Packaging

Perforated packaging comes in many forms. Each one is designed to meet a specific need in the foodservice industry. The purpose is consistent across all formats: to improve airflow, control moisture, and enhance usability. The structure and material may vary depending on how the packaging is used.

Here are six commonly used types of perforated packaging in eco-friendly foodservice:

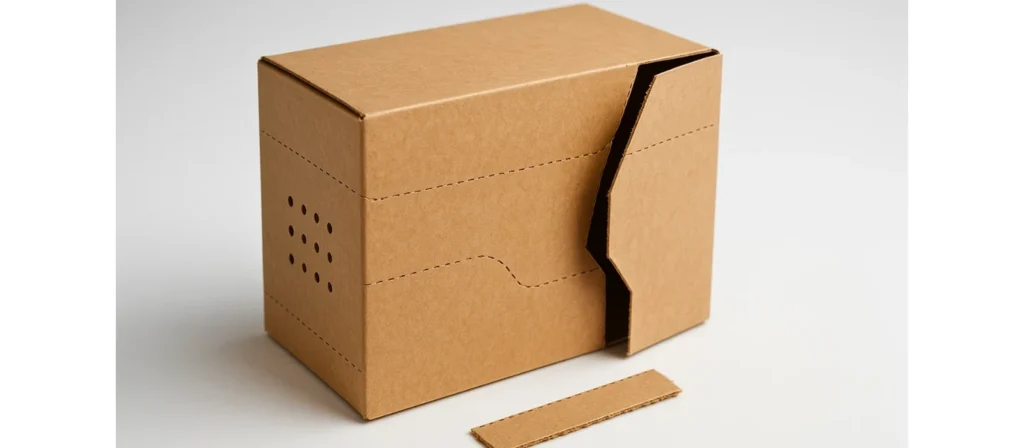

Perforated Boxes

Perforated boxes are commonly used for hot food items such as burgers, fried snacks, or grilled meals. Small ventilation holes allow steam to escape and help prevent moisture buildup inside the box. This keeps food crispy and fresh during delivery or takeaway. In compostable paperboard boxes, perforation adds breathability without sacrificing structure or sustainability.

Perforated Films

Perforated films are used as seals, wraps, or liners. Micro-perforated versions are ideal for items like sandwiches, salads, or baked goods that need moisture control. These films reduce condensation while keeping the contents visible. They are often used in heat-sealed grab-and-go packaging.

Perforated Paper

Perforated paper is often used for food wraps, tray liners, or sleeves. It allows air to circulate around baked or fried items and helps absorb excess oil. Perforation also makes it easier to tear the paper along clean lines, which is useful for portioning. This type of packaging is lightweight, compostable, and convenient for quick-service environments.

Perforated Bags

Perforated bags are ideal for packing produce, bread, or hot food. Ventilation helps maintain freshness and prevents the buildup of moisture inside the bag. These bags are typically made from kraft paper, PLA, or recycled materials. They are often used in bakeries, delis, and takeaway services. Some designs include easy-tear sections for added convenience.

Perforated Wraps

Perforated wraps are flexible and breathable, making them great for handheld foods like wraps and sandwiches. They help manage heat and moisture, keeping the food’s texture intact. At the same time, they are easy to fold, open, and eat from. These wraps are popular in cafes, food trucks, and fast-casual restaurants.

Perforated Trays

Perforated trays are designed for foods that release heat or steam such as roasted meals or baked dishes. Ventilation on the bottom or sides allows for air circulation. This supports moisture control and even heat distribution when used with ovens or warming equipment. Compostable pulp or fiber trays often include these features to improve performance.

How Perforated Packaging is Made

Creating perforated packaging is a precise process that involves a combination of technical expertise and the right equipment. The method used depends on the packaging material, the product it will hold, and the performance requirements such as ventilation, strength, and sustainability. Whether working with paper, bioplastics, or molded fiber, the goal is to produce clean, consistent perforations without damaging the structure of the material.

Below are the main manufacturing methods commonly used in the food packaging industry:

Mechanical Punching

This is one of the most common and cost-effective methods. It uses small pins or needles to physically puncture the packaging surface. In high-speed production, these pins are mounted on cylinders or rollers that the material passes through. This method is well suited for materials like kraft paper, cardboard, or flexible bioplastics. Cold needle punching maintains the material’s shape, while hot needle punching slightly melts the surface, reinforcing the edges of each hole to prevent tearing. This process is widely used for items like takeaway boxes, wraps, and liners.

Laser Perforation

Laser perforation offers high precision and consistency. A focused laser beam burns microscopic holes into the surface of the packaging. This method is ideal for applications that require controlled airflow, such as packaging for fresh produce or baked goods. Lasers can create extremely small holes in exact positions without physical contact, making it suitable for delicate or thin biodegradable films. It is particularly useful when specific oxygen or moisture transmission rates are needed to maintain food quality and shelf life.

Rotary Die-Cutting

Rotary die-cutting involves cylindrical dies that rotate continuously while the packaging material moves beneath them. The dies create clean perforations at high speed, making this method ideal for large production runs. It is often used in the production of perforated paper trays, cup carriers, or cardboard containers. This technique is efficient and reliable, especially when precision and high output are required.

Flatbed Die-Cutting

Flatbed die-cutting uses a hydraulic press to apply pressure on a fixed die board, cutting or perforating the material against a flat surface. This method is best suited for thicker packaging materials such as molded pulp trays or corrugated board. It allows for greater accuracy in more complex shapes or custom designs. Although slower than rotary systems, it is ideal for small to medium production runs where precision matters more than volume.

Perforated vs Non-Perforated Packaging: Which One is Better?

Perforated and non-perforated packaging serve different functions. The choice depends on the type of food and how it will be served or transported. Both have value in modern foodservice, but understanding when to use each is key to maintaining food quality and improving the user experience.

Perforated packaging is ideal for foods that release steam or need airflow, such as fried items, baked goods, or fresh produce. It helps prevent sogginess and maintains texture. It also adds convenience, making packaging easier to open and handle, especially in fast-paced settings.

Non-perforated packaging works best for liquids or meals that need full sealing to retain heat and prevent leaks. It offers stronger barrier protection and is preferred for items like soups, curries, or sauces.

Many businesses use both. Perforated options for crispy or fresh foods. Non-perforated for sealed, spill-prone items. Choosing the right type ensures better performance and a better dining experience.

Comparison Table: Perforated vs Non-Perforated Packaging

| Feature / Use Case | Perforated Packaging | Non-Perforated Packaging |

|---|---|---|

| Ventilation | Allows airflow and releases steam | Fully sealed, no ventilation |

| Best for | Fried food, baked goods, fresh items | Soups, sauces, liquids, heat retention |

| Moisture Control | Prevents sogginess and reduces condensation | Preserves moisture, prevents drying out |

| Ease of Use | Easier to open, fold, or tear | More secure but less convenient |

| Sustainability Advantage | Supports breathable, compostable materials | Often requires additional liners or barriers |

Applications of Perforated Packaging

Perforated packaging plays a functional role in many areas of the foodservice industry. It is not limited to a single product type or business model. From fast-casual restaurants to fresh produce suppliers, perforation is used wherever food quality, airflow, and ease of use matter.

Here are some of the most common applications in real foodservice scenarios:

Hot Food Takeaway

Items like fried chicken, grilled wraps, and roasted vegetables release steam after cooking. Perforated containers, trays, or vented lids help release that moisture, keeping the food crisp instead of soggy. This is especially useful for short-distance deliveries or in-store pickup.

Bakery and Pastry Packaging

Bread, croissants, and other baked goods often require slight ventilation to stay fresh. Perforated paper bags or wraps allow the product to breathe while still offering protection. This prevents condensation and preserves texture without compromising presentation.

Fresh Produce and Salad

Salads, herbs, and cut fruits benefit from packaging that balances airflow and humidity. Micro-perforated films or breathable trays are commonly used to extend freshness, especially in grab-and-go or refrigerated displays.

Sandwiches and Ready-to-Eat Items

Pre-packed sandwiches and wraps are often stored in perforated sleeves or wraps to prevent them from becoming too moist. These formats also make unwrapping easier for customers, improving overall convenience.

Food Trays for Quick Service

Trays with bottom or side perforation help with airflow and even heat distribution, particularly in oven-safe or heat-retaining containers. This is helpful in settings like cafeterias, food courts, or catering services.

Eco-Friendly Disposable Tableware

Perforated packaging is also applied to the outer wrapping of cutlery sets, napkin rolls, or combo packs. Perforation allows for hygienic protection while still being easy to open or separate during service.

These applications show how versatile perforated packaging can be across different food types and service formats. When thoughtfully integrated, it supports quality, efficiency, and sustainability all at once.

Tips for Choosing the Right Perforated Packaging

Choosing the right perforated packaging is not simply about selecting a material with holes. It requires understanding your food, your operations, and your sustainability goals. The right choice can help maintain food quality, reduce waste, and improve customer experience. Here are several key factors to keep in mind when making your selection:

Match the Packaging to the Food Type

Different foods behave differently after preparation. Hot and crispy items need ventilation to stay crisp, while fresh produce benefits from micro-perforations that manage moisture without drying out. Consider whether your product needs airflow, moisture release, or both, and select the perforation type accordingly.

Consider the Material

Not all materials respond the same to perforation. Compostable paper, PLA film, and molded fiber each perform differently when punched, cut, or laser-perforated. Make sure the material maintains strength after perforation and supports your environmental goals, such as being compostable or recyclable.

Focus on Function First, Then Aesthetics

Good design is important, but not at the expense of function. Ensure the perforation supports the purpose, whether that is steam release, easy tearing, or breathability. Always test how the packaging performs with real food in real conditions, such as heat, stacking, or transport.

Think About the Entire User Experience

Perforated packaging should be practical for both your team and your customers. In fast-paced kitchens, easy-to-open designs save time. For customers, good packaging adds convenience and creates a better impression. Pay attention to handling, opening, and disposal as part of the full experience.

Choose a Supplier Who Understands Food Packaging

Working with a packaging partner who knows the foodservice industry makes a difference. A knowledgeable supplier can help you select the right materials and perforation styles for your products. They can also provide custom solutions that match your brand and performance goals.

Conclusion

Perforated packaging may seem like a small detail, but in foodservice, it plays an important role. From preserving the crispness of hot meals to improving breathability for fresh items, perforation enhances both food quality and the customer experience. It supports faster service, cleaner presentation, and smarter packaging performance, especially when combined with sustainable materials.

At Million Pack, we believe packaging should do more than carry food. It should protect it, improve operations, and reflect the values of your brand. With over 20 years of experience in eco-friendly food packaging, we design and produce solutions that help food businesses serve better, waste less, and stay competitive. Whether you need custom containers, breathable wraps, or functional trays, our team is ready to help you choose packaging that works from kitchen to customer.