Every year, millions of tons of packaging waste end up in landfills and oceans, raising urgent questions about how businesses and consumers choose. With its reliance on plastics and non-renewable materials, traditional packaging once seemed the most efficient option. But today its hidden costs are impossible to ignore.

Traditional packaging (mainly made from plastics and other non-renewable materials) was the industry standard for decades because it was inexpensive and practical. However, many companies are searching for better options as environmental costs mount and global regulations tighten. This is where comparing traditional vs sustainable food packaging becomes increasingly relevant.

Sustainable solutions such as Biodegradable paper boxes, compostable plastics, and plant-based containers are not just eco-friendly alternatives; they also strengthen brand credibility and respond to customer demand for greener practices. Businesses adopting these changes often gain a competitive advantage, showing that environmental responsibility and profitability can go hand in hand.

This article will explain the key differences between traditional and sustainable approaches and outline the advantages and challenges of each. By the end, you will have a clear perspective to help you decide which direction makes the most sense for your business or lifestyle.

What is Traditional Food Packaging?

Traditional food packaging refers to the materials and processes widely used for decades, especially those reliant on non-renewable resources. These packaging types were primarily designed to preserve shelf life, reduce spoilage, and facilitate mass production and transport. While they’ve served functional purposes well, they face increased scrutiny due to their long-term environmental and health impacts.

Traditional packaging is often inexpensive and easy to source. However, it tends to be made from non-renewable, petroleum-based resources, lacks biodegradability, and contributes significantly to environmental pollution. Furthermore, many forms of traditional packaging are single-use and cannot be recycled efficiently due to contamination, composite materials, or lack of recycling infrastructure.

Types of Traditional Food Packaging

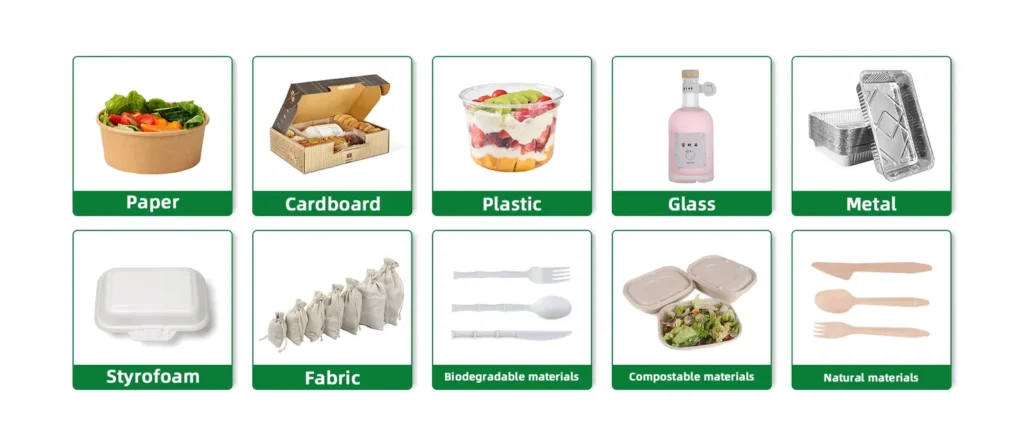

Here’s a breakdown of the most widely used traditional food packaging types in the food industry:

- Plastic Packaging

- Polystyrene (Styrofoam)

- Aluminum Foil and Cans

- Glass Jars and Bottles

- Wax-Coated Cardboard

- Laminated Pouches and Sachets

What is Sustainable Food Packaging?

Sustainable food packaging refers to solutions designed, sourced, manufactured, used, and disposed of to minimize environmental impact. The goal is to reduce waste and emissions and ensure the packaging can be reused, recycled, composted, or biodegraded without harming ecosystems.

As global awareness of climate change, resource depletion, and pollution grows, sustainable packaging has moved from being a niche concept to a mainstream business imperative. It’s especially relevant for food businesses, where packaging is a significant part of product delivery and consumer experience.

Types of Sustainable Food Packaging

Sustainable packaging options are diverse, scalable, and increasingly accessible. Key examples include:

- Compostable Packaging

- Biodegradable Plastics

- Recyclable Paper and Cardboard

- Mushroom Packaging

- Edible Packaging

- Recycled Content Packaging

Traditional vs Sustainable Food Packaging

Food businesses need a clear and objective comparison of traditional and sustainable packaging to make informed decisions. Each option has advantages and trade-offs, and understanding these across key categories will help guide strategy, procurement, and innovation.

Environmental Impact

Traditional packaging, particularly single-use plastics and mixed-material laminates, contributes to global pollution. Due to their composition, most of these materials are either non-recyclable or extremely difficult to recycle. They often end up in landfills, incinerators, or the ocean, contributing to ecosystem damage and long-term contamination.

In contrast, sustainable packaging is designed with the environment in mind. Many options are biodegradable, compostable, or made from recycled materials. Their lifecycle has a significantly lower impact on biodiversity, air and water pollution, and resource depletion.

While no packaging solution is 100% impact-free, sustainable options prioritize lower ecological footprint and greater compatibility with waste management systems.

Carbon Footprint

The carbon footprint of traditional packaging is mainly due to:

- Extraction of raw materials (e.g., petroleum for plastics)

- Energy-intensive manufacturing processes

- Global transportation of raw and finished goods

- End-of-life emissions from incineration or degradation

Sustainable packaging reduces this through:

- Use of renewable materials (e.g., agricultural waste, fast-growing plants)

- Local sourcing

- Lower production emissions

- Composting and recycling pathways that avoid methane emissions

For example, producing one ton of conventional plastic emits roughly 2–3 tons of CO₂, whereas producing one ton of molded pulp emits around 0.5 tons.

Materials

Traditional materials are selected for their durability, moisture resistance, and scalability, including:

- PE, PET, PS plastics

- Laminated foils

- Polystyrene foam

- Glass (non-renewable, energy-intensive)

- Mixed-material composites (often non-recyclable)

Sustainable materials include:

- Plant-based bioplastics (PLA, PHA)

- Bagasse, bamboo, hemp, or jute fibers

- Recycled paper and board

- Compostable films made from seaweed or starch

- Minimalist packaging with mono-material designs

Life Cycle

The lifecycle of traditional packaging often ends with disposal, while sustainable packaging encourages circular use.

| Lifecycle Stage | Traditional | Sustainable |

|---|---|---|

| Raw Materials | Non-renewable (oil, minerals) | Renewable, often from waste |

| Manufacturing | High-energy, carbon-intensive | Often lower-energy, bio-based |

| Usage | Single-use dominant | Reusable or biodegradable |

| End of Life | Landfill, incineration | Compost, recycle, reuse |

LCA (Life Cycle Analysis) tools consistently show that sustainable packaging has a more favorable long-term profile even when more expensive up front.

Cost-Effectiveness

At face value, sustainable packaging may appear costlier. Bioplastics and compostable trays often cost more per unit than polystyrene or plastic. However, this view neglects broader financial realities:

- Regulatory costs associated with plastic bans and waste management

- Reputational risk tied to environmentally damaging practices

- Consumer loyalty and pricing power gained from sustainable branding

Long-term, sustainable packaging can lead to savings in waste disposal, improved customer retention, and eligibility for tax incentives or sustainability-linked financing.

Many companies report an eventual ROI increase after switching to eco-friendly packaging—not from cutting corners, but from aligning with consumer values and future-proofing their operations.

Health Risks

The health implications of packaging materials are gaining increasing scrutiny. Traditional packaging often leaches harmful chemicals like BPA, phthalates, and styrene, particularly when heated or used for fatty/acidic foods. These substances are linked to hormonal disruption, cancer, and developmental issues.

Sustainable packaging materials are typically free from such chemicals, especially when certified by third-party organizations (e.g., USDA BioPreferred, BPI). Plant-based and compostable options are designed to interact safely with food, even under heat or moisture.

This shift also reduces corporate responsibility. With increasing litigation and media attention on packaging safety, choosing non-toxic, transparent materials is ethical and legally prudent.

Why Sustainable Packaging Is So Important for Food Companies?

Today’s customers expect transparency and responsibility from the brands they support. Packaging is one of the most visible expressions of these values. Businesses using eco-friendly materials signal a more profound commitment to environmental stewardship. An attribute that builds trust, loyalty, and differentiation in competitive markets.

Beyond consumer perception, governments worldwide are introducing strict packaging regulations, including bans on single-use plastics, recycling mandates, and producer responsibility laws. Adaptability failure could result in fines, product restrictions, or reputational damage.

From a business standpoint, sustainable packaging often results in long-term cost advantages. Although initial costs can be higher, savings emerge through reduced waste fees, operational efficiencies, and eligibility for green incentives or certifications that open up new sales opportunities.

Most importantly, sustainable packaging helps future-proof your business. As raw materials become scarce, climate impact becomes a focal point, and ESG reporting becomes mandatory, those companies that lead in sustainability will be best positioned for resilience and growth.

How to Transition from Traditional to Sustainable Packaging?

Transitioning from traditional to sustainable packaging doesn’t require an overhaul of your entire operation overnight. In fact, businesses that succeed in this shift often take a strategic and phased approach, allowing time for product testing, cost assessment, and stakeholder education.

1. Assess Your Current Packaging System

Before implementing any changes, conduct a detailed audit of your existing packaging. Identify what materials are used, how much waste they generate, and what percentage is recyclable or compostable under local conditions.

2. Define Clear, Achievable Goals

Set sustainability objectives that are measurable and time-bound. These might include:

- Eliminating PVC by a specific year

- Switching 50% of packaging to recyclable materials

- Reducing packaging weight by 20%

If applicable, these goals should align with broader environmental, social, and governance (ESG) initiatives.

3. Research Alternatives Strategically

Not all sustainable materials are appropriate for every product. Factors like shelf life, food type, humidity, temperature, and transportation distance all affect material choice. For instance, compostable trays may not perform well for high-moisture items without added coatings.

Partner with credible suppliers that provide third-party certifications for compostability, recyclability, or food safety standards.

4. Start Small with Pilot Programs

Instead of overhauling all packaging at once, select one product line to test a sustainable alternative. Monitor consumer feedback, shelf performance, and operational feasibility before scaling.

5. Train Teams and Inform Consumers

Internally, staff should understand new packaging workflows. Externally, educate consumers on clear labeling and communication about properly disposing of the new packaging.

6. Track Impact and Adjust

Monitor costs, waste reduction, and customer response. Use these insights to justify broader adoption and optimize your packaging strategy over time.

Transitioning doesn’t require perfection overnight—it needs consistent, strategic improvement that reflects your brand values and customer expectations.

FAQs

- Is sustainable packaging safe for all types of food?

Yes. Many sustainable materials meet FDA and international safety standards and offer protective properties similar to those of plastic and other traditional materials. - How can I know if a packaging material is truly sustainable?

Look for third-party certifications like BPI, FSC, and USDA BioPreferred. Avoid products that make vague or unverified claims. - How do I dispose of compostable or biodegradable packaging?

Follow local waste management rules. Some items require industrial composting, while others can break down in home compost bins. - Can sustainable packaging protect food as effectively as traditional materials?

Absolutely. With modern innovations, compostable and recyclable materials now provide comparable—sometimes superior—barrier protection, shelf stability, and heat resistance. - Are there government incentives for sustainable packaging?

In many regions, yes. Some governments offer grants, tax incentives, or reduced waste fees for businesses using certified sustainable packaging materials. - Does sustainable packaging affect food shelf life?

While some early versions did, newer sustainable materials have advanced significantly. With proper selection and testing, they can match or exceed the shelf-life performance of traditional packaging.

Conclusion

The debate between traditional vs sustainable food packaging is no longer theoretical. It’s a real, urgent, and business-critical issue for any food company aiming for longevity, relevance, and ethical alignment.

While traditional packaging still holds functional advantages in some cases, the environmental, regulatory, and brand-related downsides are becoming too significant to ignore. Sustainable packaging represents not just an environmental responsibility but a growth opportunity.

Transitioning doesn’t mean sacrificing performance or profit—it means rethinking design, materials, and messaging to benefit your business, your consumers, and the planet.