GSM paper refers to the weight of paper measured in grams per square meter, and it is one of the most important indicators used to evaluate packaging materials. When people ask what is GSM paper, they are really asking how to read the “weight” of paper. In simple terms, GSM tells you how heavy and dense a sheet of paper is, which directly affects its strength, stiffness, thickness, and suitability for different packaging uses.

In packaging applications, GSM is not just a technical number. It influences how a paper bag holds its shape, how a cup resists heat and moisture, and how well printed graphics appear on the surface. Choosing the right GSM helps balance durability, cost, and user experience, especially in food packaging, where performance and safety matter.

Understanding what GSM paper means also helps buyers communicate clearly with suppliers. When specifications include GSM, both sides can quickly align on expectations for material performance, reducing the risk of packaging that looks acceptable on paper but fails during transport or daily use.

For example, a takeaway food box made from 300 GSM paperboard will generally feel firmer and more resistant to bending than one made from 230 GSM paper, even if both use the same coating and design. This small difference in GSM can determine whether packaging performs reliably in real restaurant conditions.

Why Are There Different GSM Values?

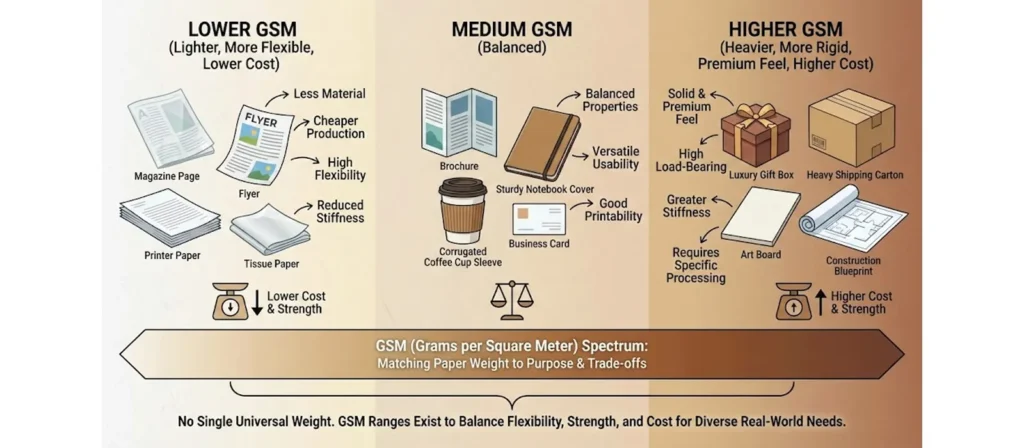

Different GSM values exist because paper and board have to do very different jobs in the real world. A magazine page, a coffee cup sleeve, and a luxury gift box all need their own balance of thickness, stiffness, and flexibility. One single “universal” weight could never handle such a wide range of uses.

Different GSM values also reflect trade-offs between cost, usability, and strength. Lower GSM papers use less material and are cheaper to produce, but they sacrifice stiffness and load-bearing capacity. Higher GSM papers feel more solid and premium, yet they cost more and may require different cutting, printing, or forming processes. GSM helps buyers select paper that matches real-world needs instead of relying on appearance alone.

Outside packaging, GSM plays a role in publishing, advertising, stationery, construction documentation, and even art. A brochure, a shipping carton, and a notebook cover all rely on paper, but each requires a very different balance of flexibility and strength. That is why GSM ranges exist rather than a single standard weight.

Common GSM Values

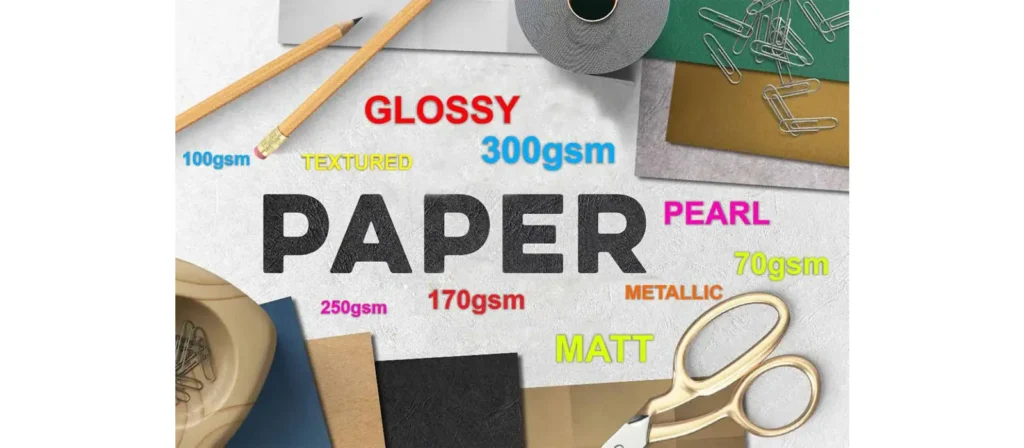

When discussing paper weight, GSM values are often grouped into practical ranges. Each range corresponds to typical performance characteristics and common applications, making it easier to choose the right paper for a specific task.

- 80–100 GSM

This range is lightweight and flexible. It is commonly used for office paper, flyers, leaflets, and envelopes. Paper in this GSM range runs smoothly through printers, folds easily, and keeps mailing costs low, but it offers limited rigidity. - 120–170 GSM

Medium-weight paper that feels noticeably thicker and more durable. It is often used for brochures, posters, presentation inserts, and premium stationery. This range balances print quality and strength while remaining easy to handle and finish. - 200–300 GSM

Heavy paper or light paperboard with good stiffness. Typical uses include postcards, greeting cards, folders, menu covers, and some light packaging. It holds its shape well and supports high-quality printing without feeling bulky. - 300+ GSM

Very thick paperboard designed for structural support. It is widely used for rigid packaging, box sleeves, covers, and display materials. Paper above 300 GSM provides strength and a premium feel but requires specialized cutting and forming equipment.

Different Paper GSM Weights and Applications

In printing, design, and packaging, you will see a few GSM “zones” getting used again and again. Lighter weights focus on flexibility and low cost, while heavier boards focus on protection and a solid, premium hand-feel. In food packaging, the choice of GSM also has to work with temperature, moisture, grease, and transport conditions, so the right range can vary a lot between, say, a salad bowl and a coffee cup sleeve.

Paper GSM directly influences how paper performs in real use. Different weights suit different tasks, from everyday printing to demanding food service environments. Below, we look at how GSM values apply across industries, starting with general uses and then moving into specific food packaging applications where GSM selection is especially critical.

Printing and Publishing Materials

In printing and publishing, GSM determines readability, durability, and handling comfort. Lighter papers around 80–100 GSM are widely used for books, manuals, and office documents because they are easy to turn and economical for large volumes. Higher GSM papers, typically 120–170 GSM, are chosen for magazines, catalogs, and marketing inserts where better opacity and print sharpness are needed. The GSM must support ink coverage without warping while keeping the final product practical for distribution.

Stationery and Promotional Products

Stationery and promotional items rely on GSM to communicate quality at first touch. Business cards, postcards, and premium flyers usually fall between 200–300 GSM, giving them a firm feel that resists bending. This GSM range supports embossing, spot finishes, and vivid color printing. Choosing too low a GSM can make materials feel cheap, while overly high GSM may complicate cutting and finishing.

Lightweight Food Wrapping and Inner Liners

For food packaging, lower GSM papers are commonly used as wraps, liners, or inner layers. Papers in the 40–80 GSM range are often applied to sandwich wraps, bakery liners, and greaseproof paper sheets for oily or saucy foods. These papers focus on flexibility, food-contact safety, and barrier coatings rather than structural strength, keeping materials economical and easy to fold snugly around different food items.

Paper Cups, Bowls, and Formed Containers

Medium GSM paperboard is essential for formed food containers such as paper cups, soup bowls, and ice cream tubs. GSM values typically range from 180–280 GSM, depending on the product and coating. This weight provides enough stiffness to hold shape during filling and handling, while still allowing smooth forming and sealing. The right GSM also helps containers resist heat and moisture without excessive material use.

Rigid Food Boxes and Takeaway Packaging

Heavier GSM paperboard, often 300 GSM and above, is used for takeaway boxes, food cartons, and bakery boxes that must protect contents during transport. These applications demand strength, stackability, and resistance to crushing. Higher GSM improves structural integrity and gives packaging a more premium feel, which is especially important for branded food service and delivery-focused businesses.

Why GSM Matters in Packaging

GSM is one of the most practical indicators of whether packaging will perform as expected in real conditions. It affects strength, stiffness, handling, cost, and even how packaging is perceived by end users. Choosing the wrong GSM does not just change how paper feels, it can lead to functional problems during production, transport, and daily use. Both extremes, too low or too high, carry their own risks.

When GSM Is Too Low

When GSM is too low for the job, the first issue you see is a lack of stiffness. Cartons bend too easily, lids lose their grip, and cups can feel soft or unstable in the hand. For food, that can show up as a burger box that bows when you pick it up, a noodle bowl that feels weak around the rim, or a cup that flexes when filled with hot coffee.

Low GSM also means less resistance to moisture and grease, especially if the material has minimal coating. Sauces, oils, and steam can quickly weaken thin paper, leading to soggy spots, deformation, or even tearing. In extreme cases, the packaging can leak, stain bags, or collapse before the food reaches the customer, which hurts both the dining experience and your brand image.

From a practical standpoint, underweight packaging can cause problems in handling and logistics, too. Stacks of low-GSM trays or boxes may not support their own weight in transit, so you end up with crushed items at the bottom of a pile. Even if everything technically arrives in one piece, the packaging can look tired and dented, sending the wrong message about quality and care.

When GSM Is Too High

At the other end, using a GSM that is too high sounds safe, but it creates its own set of headaches. Heavy boards add cost because you are paying for extra fiber that you may not really need. That extra weight can also push up shipping fees, especially when you multiply it across thousands of boxes or cups going out every week.

Overly thick paper or board can make packaging feel bulky and awkward to handle. Lids may be harder to close securely, folds may crack if the board is too stiff for the design, and customers might struggle to open or flatten the packaging after use. In tight storage spaces, such as food trucks or small kitchens, high-GSM items take up more room, which reduces the number of units you can store on-site.

There is also an environmental angle. Using higher GSM than necessary usually means more raw material and more waste. Even if the paper is recyclable or compostable, you are still consuming more resources than needed to achieve the same functional result. Once you understand what is GSM paper and how it relates to performance, you can right-size your packaging: strong enough to protect the food, yet lean enough to support cost control and sustainability goals.

How to choose the right GSM for your packaging

Choosing GSM starts with one simple question: what does your packaging need to survive from packing line to customer? When you understand what is GSM paper and how thickness affects stiffness, insulation, and cost, it becomes much easier to match the number to the job. Think about weight of the product, how it is handled, and the kind of experience you want your customer to have when they pick it up or open it.

You also need to think about the journey. Will the item be eaten on-site, carried for a few minutes, or sent across town by delivery riders? Will it sit in a fridge, under a heat lamp, or on a retail shelf for days? These details shape whether a light, medium, or heavy GSM is enough. The right choice avoids both under-built packs that fail and over-built packs that waste material.

Finally, look at your printing and branding needs. High-impact graphics and a premium look tend to work better on medium to higher GSM boards with good opacity and surface smoothness. Simple, text-heavy designs or plain functional packs can often use lighter GSM grades. When you combine the product, journey, and brand image, the ideal GSM range usually becomes quite clear.

Food Packaging

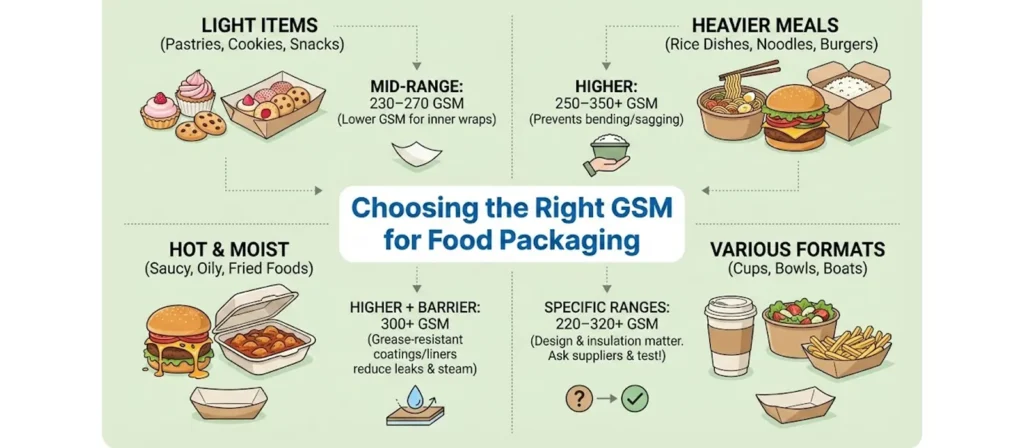

For food packaging, start by matching GSM to the type and weight of food. Light items like pastries, cookies, or small snacks can often use mid-range boards around 230–270 GSM for cartons, or even lower GSM sheets for inner wraps. Heavier meals, such as rice dishes, noodles, or burgers with sides, usually need 250–350 GSM or higher so that the box or bowl does not bend or sag when carried with one hand or stacked in a delivery bag.

Temperature and moisture are just as important. Hot, saucy dishes or oily fried foods place extra stress on packaging. In these cases, a higher GSM board with suitable coatings or liners can keep containers firm and reduce the risk of leaks. For example, a 300+ GSM clamshell with a grease-resistant barrier is far better suited to a loaded burger than a thin carton. Cold salads or dry bakery items can sometimes use slightly lower GSM because they put less pressure on the material.

Then think about format. Paper cups for hot drinks often use board in the 220–320 GSM range, possibly with a sleeve or double wall for insulation. Salad bowls and noodle bowls usually sit in a similar or slightly higher range so the rim stays rigid when stacked. Food boats for fries or street snacks can work well in the mid-200 GSM range if the design supports the sides. If you are unsure where to start, ask suppliers for GSM recommendations for each format and test them with your real menu items.

Retail Packaging

Retail packaging has a different goal: it must protect and present the product on the shelf at the same time. For small, light goods such as cosmetics, phone accessories, or stationery, many brands use 200–300 GSM boxboard or folding cartons. This gives enough stiffness to keep shape, while still allowing clean folds and sharp edges that look tidy. Hang tags and backing cards for products on hooks might use similar or slightly lower GSM, depending on size.

For premium products that should feel luxurious, you might move into 300–400 GSM or even higher, sometimes combined with laminations or special finishes. Think of high-end perfume boxes or gift packaging that feels solid when you pick it up. Here, GSM helps create that sense of weight and quality. At the same time, you must ensure the board is not so thick that machines struggle to fold or glue it, or that customers find it hard to open.

If your product is fragile or has glass components, the outer packaging GSM works together with internal structures such as inserts, dividers, or wraps. The outer box might use a mid-to-high GSM folding board, while inner pieces use lighter board to hold the product in place. When you understand what is GSM paper, you can choose a slightly lighter outer board and add smart internal supports, instead of using very heavy board everywhere and driving up material costs.

Industrial and Commercial Packaging

Industrial and commercial packaging typically involves heavier loads, longer storage, and more demanding transport conditions. Here, GSM choices often combine with multi-layer structures like corrugated board. For example, a retail-ready tray for bottled drinks or canned foods may use high GSM liner papers on the corrugated board to give strength and tear resistance at the edges and corners. The exact GSM can vary, but it is usually much higher than standard office or brochure paper.

In business-to-business packaging, such as shipping components, spare parts, or bulk ingredients, functionality comes first. You might use high-GSM kraft liners for outer boxes and lighter GSM sheets for inner dividers and protective wraps. A sturdy outer structure supported by smart interior partitions can protect heavy items better than simply increasing GSM of every layer. That way, you reduce waste and still avoid damage during transport and handling.

Commercial printed materials, like large-format menus, point-of-sale displays, or pallet-top signs, also rely on GSM. Freestanding counter displays may use 300–400 GSM or higher to stay upright, while hanging posters might work well at 170–250 GSM because they do not carry weight, they just need to stay flat. By understanding what is GSM paper and matching the weight to the job, you can design packaging and commercial materials that handle real-world conditions without overspending on fiber.

GSM vs LBS Explained

When you look at global paper or packaging specs, you might see GSM in one place and LBS (pounds) in another. GSM, as you already know from what is GSM paper, measures grams per square meter and is independent of sheet size. LBS, on the other hand, is a “basis weight” system used mainly in the US. It measures how many pounds a ream of paper (usually 500 sheets) weighs at a specific sheet size for that paper type.

That twist is what makes LBS confusing: the base sheet size is different for bond paper, cover stock, text paper, and so on. So a 65 lb cover stock is nothing like a 65 lb text stock. Without knowing the paper category and base size, you cannot read LBS values at a glance the way you can with GSM. For packaging buyers working with international suppliers, this can create misunderstandings if you do not translate between GSM and LBS properly.

In practice, most packaging professionals prefer GSM because it gives a direct, size-independent measure of weight and thickness. However, you may still receive quotes or samples that use LBS, especially from North American paper mills or printers. The table below gives a simple comparison of how GSM and LBS differ and how common values roughly line up for typical products.

| Aspect | GSM | LBS |

|---|---|---|

| Full name | Grams per square meter | Pounds |

| Measurement basis | Weight of 1 square meter of paper | Weight of a ream based on standard sheet size |

| Unit system | Metric | Imperial |

| Consistency | Same meaning across all paper types | Varies by paper category |

| Ease of comparison | Easy to compare between materials | Can be confusing without conversion |

| Common usage | Global packaging and manufacturing | Mainly used in North America |

| Accuracy for packaging | High | Medium |

| Best for beginners | Yes | No |

When you understand what is GSM paper and how it stacks up against LBS, it becomes much easier to compare samples from different regions. A good rule of thumb is to request GSM values even when suppliers quote in LBS, so you can standardize your specifications and choose consistent paper or board weights across all your packaging lines.

Common GSM Myths in Packaging

One common myth is that GSM alone tells you exactly how thick a paper or board will feel. In reality, what is GSM paper is just part of the story. Different fibers, coatings, and manufacturing methods can make two sheets with the same GSM feel very different in stiffness and bulk. A high-bulk eco board can feel thicker and more rigid than a standard board at the same GSM, so you cannot rely on the number alone to judge “how thick” it will seem.

Another frequent misunderstanding is that a higher GSM is always better. Many people assume that if 250 GSM works, 350 GSM must be safer, but that often leads to over-engineered packaging. Too much GSM can make folds crack, boxes hard to close, and storage less efficient. The smarter approach is to match GSM to the exact job: just enough strength and rigidity to protect the food and support branding, without adding unnecessary material and cost.

A third myth is that the same GSM will behave identically in every application. Once you know what is GSM paper, it is easy to forget other variables like coating, moisture resistance, and design shape. A 300 GSM uncoated board used for a dry bakery box will not perform the same as a 300 GSM coated board used for oily takeaway meals. The structure of the box, the type of food, and even delivery conditions all influence how that GSM performs in real life, so testing with your actual product is essential.

Conclusion

By now, the question of what is GSM paper should feel much less mysterious. GSM is simply a way of measuring how heavy a square meter of paper or board is, but that single number has a huge impact on how your packaging looks, feels, and performs. The right GSM can mean the difference between a sturdy takeaway box that survives delivery and a flimsy one that arrives bent, soggy, or leaking.

For anyone involved in food packaging, retail packaging, or even industrial materials, GSM is a practical tool rather than a technical detail. When you match GSM to product weight, temperature, moisture, transport distance, and the experience you want customers to have, you can narrow down the best range quickly. Instead of guessing, you are making intentional choices that support performance, cost control, and sustainability at the same time.

It is also important to remember that GSM works alongside other factors: coatings, barrier layers, board type, and pack design. Two materials with the same GSM can behave very differently, so samples and real-world testing are always worth the effort. When you combine a clear understanding of what is GSM paper with hands-on trials, you end up with packaging that feels right in the hand, performs reliably in use, and supports the image of your brand.