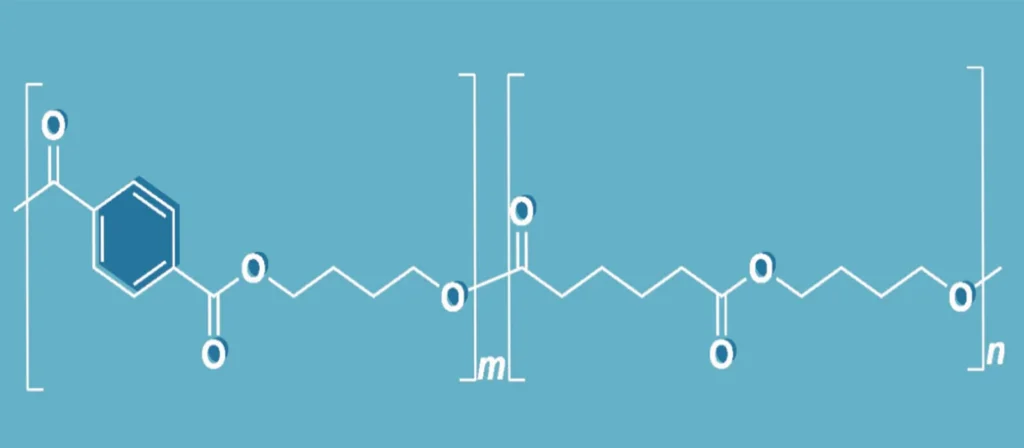

PBAT stands for polybutylene adipate terephthalate. It is a copolymer made by combining monomers such as adipic acid, 1,4-butanediol, and terephthalic acid. The resulting material includes both aliphatic and aromatic polyester segments, which gives it flexibility and durability while also enabling it to degrade under the right conditions. Although some variants can include bio-based content. What makes PBAT unique is its ability to break down into environmentally benign substances when exposed to industrial composting settings.

In packaging, especially food-related uses, PBAT is often considered a food grade plastic. It meets various purity and safety standards required for direct contact with food products. PBAT’s capacity to function like conventional plastic while offering an improved end-of-life profile makes it an increasingly attractive choice in sustainability-conscious markets.

If you are evaluating materials that combine performance, food safety, and environmental responsibility, learning What Is PBAT is an important starting point. This article will guide you through what PBAT is, how it is produced, where it is used in modern industry, and whether it can serve as a meaningful step toward a more sustainable plastic future.

How is PBAT made ?

The production process generally involves a two-step polycondensation method. First, intermediate esters are formed, and then these are reacted at elevated temperatures under vacuum conditions with catalysts like titanium-based compounds to build up the final polymer chains. Manufacturers can adjust the ratio of aliphatic to aromatic components to control flexibility, crystallinity, and melting point.Once the polymer is formed, it is cooled, pelletized, and then processed into films, coatings, or molded items using conventional plastic manufacturing equipment. PBAT can be extruded, blown into film, or molded depending on the final product’s requirement.

From a functional perspective, the aliphatic parts of PBAT allow microbial organisms to attack the polymer, while the aromatic portions provide the needed strength for packaging and other industrial applications. This duality is what sets PBAT apart from many other polymers, including other biodegradable plastics that may lack either the mechanical strength or the ability to degrade efficiently.Because it can be used in food-contact applications, PBAT also needs to meet the regulatory standards set for food grade plastic. This involves maintaining chemical purity, ensuring no toxic migration into food, and being manufactured under strict hygienic conditions.

In summary, PBAT is made using controlled chemical processes that blend flexibility, durability, and biodegradability. It is a material that offers both environmental and functional advantages, especially in the packaging industry.

Why is PBAT considered biodegradable ?

PBAT is considered biodegradable due to the nature of its chemical bonds and how they respond to environmental conditions. The aliphatic segments in the polymer chain are particularly susceptible to hydrolysis, a chemical reaction with water, which is then followed by enzymatic breakdown by microbes.

Once these chemical bonds are broken, smaller molecular fragments are released that microorganisms can consume. These organisms convert PBAT into carbon dioxide, water, and biomass under aerobic conditions. This process mimics natural decomposition but requires specific conditions like warmth, moisture, and the presence of microorganisms.

Most certifications for PBAT’s biodegradability are based on industrial composting standards. These settings provide the high temperatures and microbial concentrations necessary for efficient degradation. Under such conditions, PBAT-based products can break down in a matter of weeks to a few months.

Outside of controlled environments, the rate of biodegradation can vary. In marine environments or landfills with little oxygen and low microbial activity, PBAT may persist for a much longer time. This is why clear labeling and proper disposal pathways are essential.

It is also important to distinguish between biodegradable and compostable. All compostable materials are biodegradable, but not all biodegradable materials meet the strict timelines and conditions required for composting certifications. PBAT, however, can meet both criteria when produced and processed correctly.

Its ability to degrade in the right settings makes PBAT a valuable member of the biodegradable plastics family. Especially in food grade plastic applications, this ensures packaging doesn’t contribute to long-term pollution if disposed of correctly.

What are the common uses of PBAT

PBAT is a highly adaptable material, finding applications across multiple industries due to its flexibility, biodegradability, and ability to blend with other materials. Below are the primary areas where PBAT is utilized:

- Flexible Packaging Films

One of the largest markets for PBAT is in the production of thin, flexible films used for shopping bags, produce sacks, and compostable waste liners. Its mechanical properties closely resemble those of polyethylene, making it a practical substitute in applications that demand durability and elasticity. These films are designed for short-term use and are often disposed of with organic waste, making their compostable nature especially advantageous. - Compostable Food Packaging

In the food packaging industry, PBAT is blended with other bioplastics to produce pouches, wrappers, and laminated films. These combinations provide not only the necessary strength and barrier performance but also enable industrial composting after disposal. As a food grade plastic, PBAT-based packaging must comply with strict food safety regulations, ensuring that it poses no risk to health while still offering sustainable end-of-life options. - Agricultural Mulch Films

PBAT is used in farming for biodegradable mulch films, which are laid over soil to control temperature, conserve moisture, and suppress weed growth. These films serve a dual purpose: enhancing crop yields during the growing season and breaking down naturally after use, which eliminates the labor-intensive process of film collection and disposal. The use of PBAT in agriculture demonstrates how sustainability and functionality can coexist in demanding environments. - Biodegradable Utensils and Trays

PBAT is increasingly found in molded products such as disposable forks, spoons, trays, and plates. These items are particularly valuable in catering, hospitality, and event management sectors that aim to reduce their environmental impact. While PBAT may not yet be the primary material in this category, its growing use signals a shift toward more eco-conscious consumption in public and commercial spaces. - Blended Bioplastic Products

PBAT is rarely used on its own. It is often combined with materials like polylactic acid (PLA) or thermoplastic starch to create compounds that meet diverse performance criteria. Blending allows manufacturers to tailor the strength, flexibility, and compostability of products, depending on the specific requirements of each application. This flexibility in formulation makes PBAT a valuable component in the toolkit of sustainable product design. - Coatings for Paper and Cardboard

Another significant application of PBAT is as a moisture-resistant coating on paper-based products. By replacing traditional polyethylene coatings, PBAT enables the creation of fully compostable or recyclable packaging items such as takeaway containers, drink cups, and laminated cartons. These products are not only functionally robust but also align with circular economy principles.

PBAT’s role across these applications highlights its versatility as a sustainable material that supports the transition away from persistent plastics. Its integration into both single-use and industrial products reinforces its importance in future material innovation.

What are the pros and cons of PBAT

This table presents a detailed comparison between the strengths and limitations of PBAT in packaging and product applications:

| Pros of PBAT | Cons of PBAT |

|---|---|

| Excellent flexibility and toughness, ideal for packaging and carry films | Higher production costs than standard fossil-based plastics like polyethylene |

| Compatible with existing manufacturing lines, reducing conversion investment | May not provide strong moisture or gas barrier properties in some applications |

| Industrially compostable under certified conditions, lowering environmental harm | Requires specific composting facilities, limiting effectiveness in many regions |

| Safe for food contact use with proper compliance to regulations | Difficult to recycle in mixed plastic waste streams, increasing contamination risk |

| Supports sustainability goals in single-use packaging scenarios | Limited shelf life and heat resistance compared to engineered plastic alternatives |

| Can be blended with other bioplastics for performance optimization | Not suitable for long-term storage or heavy-duty industrial applications |

Summary: PBAT is a promising option for sustainable, short-life products like bags, films, and food packaging. However, its full benefits depend on proper end-of-life handling and infrastructure availability.

What is the difference between PBAT and PLA

| Aspect | PBAT | PLA (Polylactic Acid) |

|---|---|---|

| Chemical Origin | Petroleum-based with potential partial bio-content | Fully bio-based (derived from corn starch, sugarcane, etc.) |

| Structure | Copolyester (aliphatic-aromatic) | Aliphatic polyester |

| Flexibility | Highly flexible and tough | Brittle unless blended with other materials |

| Processing | Compatible with conventional plastic equipment | Requires specific thermal settings |

| Biodegradability | Degrades under industrial composting conditions | Degrades under industrial composting, slower in natural settings |

| Composting Certification | Meets ASTM D6400 and EN 13432 standards | Also meets ASTM D6400 and EN 13432 standards |

| Recyclability | Not commonly recycled | Difficult to recycle through standard systems |

| Transparency | Generally opaque | Can be made transparent |

| Typical Applications | Compostable bags, agricultural films, food grade plastic wraps | Rigid packaging, bottles, cutlery, trays |

| Heat Resistance | Lower than conventional plastics | Typically lower than PBAT unless modified |

| Cost | Higher than polyethylene, but often lower than PLA | Generally more expensive due to bio-based feedstock |

What regulations govern PBAT worldwide

Understanding the regulatory environment is essential for the safe and effective application of PBAT. Though regional differences exist, most legal frameworks focus on compostability standards, food safety, and environmental impact.

- United States: The United States has established clear standards for compostable plastics through ASTM D6400 and ASTM D6868. These specify the rate and completeness of biodegradation as well as the absence of harmful residues following decomposition under industrial composting conditions. Additionally, any PBAT intended for food packaging must comply with the U.S. Food and Drug Administration (FDA) requirements, which are outlined in Title 21 of the Code of Federal Regulations. These include strict limits on substance migration, chemical purity, and manufacturing under sanitary conditions to qualify as food grade plastic.

- European Union: The European Union enforces compostability requirements through the EN 13432 standard, which mandates that compostable materials must disintegrate by 90 percent within 12 weeks and biodegrade into carbon dioxide, water, and biomass without leaving toxic residues. For food packaging applications, the EU also applies Regulation 10/2011 on plastic materials and articles intended to come into contact with food. This regulation includes a positive list of authorized substances, detailed migration limits, and mandatory compliance testing. PBAT used in this region must meet both compostability and food-contact safety standards to be legally marketed.

- China: China has issued several national standards and policy frameworks aimed at restricting traditional plastic usage and encouraging alternatives such as PBAT. Although still evolving, these regulations include the GB/T 41010 standard for biodegradable plastics and local municipal guidelines that outline permitted applications in packaging, food delivery, and retail sectors. Materials used in food contact applications must pass safety evaluations overseen by the National Health Commission (NHC), which controls limits on chemical migration and material composition to ensure food grade quality. Products claiming biodegradability must also meet designated labeling, testing, and documentation requirements.

- Global Certifications and Third-Party Validation: Around the world, third-party certifications serve as a benchmark for regulatory and consumer assurance. Certification bodies evaluate whether PBAT-based materials meet international standards such as ISO 17088 (specifications for compostable plastics), ASTM D6866 (for bio-based carbon content), and regional food-contact laws. These certifications assess biodegradability, compostability, migration behavior, and chemical purity. Independent verification ensures that product claims are credible and allows manufacturers to position their materials with integrity across various markets.

Manufacturers using PBAT in food packaging and other regulated applications must rigorously document compliance with national and international laws. Simply labeling a product as biodegradable is not sufficient. It must also meet the technical, chemical, and performance criteria established by these regulatory frameworks to avoid legal risks and ensure proper end-of-life management.

Is PBAT the future of sustainable plastics

PBAT is increasingly viewed as a transitional solution in the global shift toward sustainability. It offers practical benefits while aligning with the demand for reduced environmental impact.Its biggest strength lies in combining familiar plastic processing with end-of-life advantages. Industries can adopt PBAT without overhauling their equipment or supply chains. Consumers benefit from packaging that performs well and can degrade under the right conditions.

However, challenges remain. Without widespread composting facilities, the promise of biodegradability often falls short. Additionally, PBAT faces competition from other materials, including recycled plastics and newer bio-based alternatives.The future of PBAT will depend on improving infrastructure, reducing costs, and maintaining regulatory support. As governments ban certain single-use plastics and encourage compostable alternatives, PBAT will likely continue to play a role.

While it may not replace all plastic types, it is a strong candidate for specific applications like food packaging, organic waste bags, and agricultural films. As part of a larger materials strategy, PBAT can contribute meaningfully to sustainability goals.

Conclusion

PBAT represents a practical step forward for industries seeking materials that align with modern sustainability expectations without sacrificing essential performance. Its balance of flexibility, compostability, and compatibility with food packaging makes it a compelling choice for applications where short product lifecycles and responsible disposal are closely linked. Although infrastructure and cost challenges still exist, PBAT remains one of the most adaptable solutions among current biodegradable plastics.

As global regulations tighten and consumer preferences shift toward environmentally responsible materials, interest in PBAT will continue to rise. For companies evaluating greener packaging strategies, understanding the capabilities and limitations of PBAT is becoming increasingly important. By choosing materials that meet both performance needs and environmental goals, businesses can take meaningful steps toward a more sustainable future while preparing for the evolving demands of the global market。

FAQs

1. What is PBAT in simple terms

PBAT is a type of plastic that can break down naturally under composting conditions while still behaving like flexible packaging materials.

2. Can PBAT be used for food packaging

Yes, PBAT is suitable for food grade plastic applications, provided it meets safety and migration standards.

3. Does PBAT degrade in all environments

No, PBAT requires specific composting conditions to degrade effectively. It does not break down quickly in marine or landfill settings.

4. Is PBAT fully bio-based

Not necessarily. PBAT can contain petroleum-derived monomers, although some versions may include bio-based content.

5. Is PBAT recyclable

PBAT is not typically recyclable through standard plastic recycling systems and is better suited for composting.

6. What industries benefit most from PBAT

Packaging, agriculture, and food service industries benefit from PBAT due to its performance and environmental profile.