In recent years, global efforts to reduce plastic waste have sparked growing interest in bio-based alternatives. Among these, PLA plastic (also known as polylactic acid) has become one of the most widely used materials.

But with growing demand comes questions. Is PLA plastic truly compostable? Does it break down in a backyard compost pile like kitchen scraps? Or does it require special handling? More importantly, what happens if it’s not handled properly? Can it still live up to its environmental promise?

This article takes a deep dive into PLA plastic, exploring its manufacture and use scenarios, its advantages, and its drawbacks. Whether you’re a business owner, an environmental advocate, or simply a curious consumer, understanding the entire life cycle of PLA plastic is crucial to making informed and responsible choices.

What is PLA Plastic?

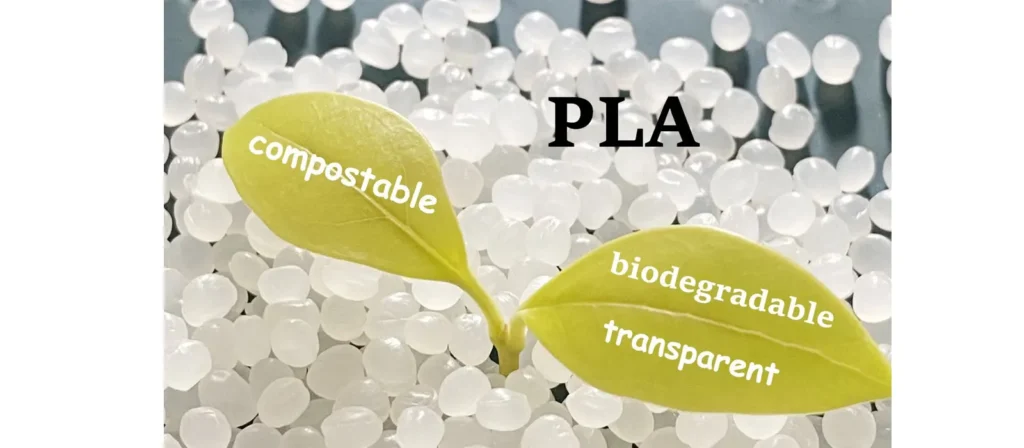

Polylactide, abbreviated as PLA plastic, is a type of bioplastic made from renewable plant-based resources like corn starch, sugarcane, or cassava. It falls under the category of thermoplastics, meaning it becomes moldable when heated and solidifies upon cooling. Unlike conventional plastics derived from petroleum, PLA is produced through the fermentation of natural sugars into lactic acid, which is then polymerized into polylactic acid.

Chemically, PLA belongs to the polyester family. Its molecular structure allows it to mimic the characteristics of traditional plastics, making it a viable alternative in many industrial and commercial applications. It is rigid, transparent in its natural state, and has a relatively low melting point compared to petrochemical-based plastics.

Importantly, PLA is categorized as an aliphatic polyester, which gives it its biodegradability under specific conditions. Because it’s plant-based, consumers are often confused about whether it’s suitable for home composting or can be easily recycled.

What Are the Pros of PLA?

Comparable to PET Plastics

PLA shares several characteristics with conventional plastics such as PET. It offers good visual clarity, is lightweight, and can be molded using existing plastic manufacturing equipment. For industries seeking more sustainable options without needing to redesign their entire production line, PLA presents a practical alternative.The following is a comparison between PLA and PEL:

| Aspect | PLA (Polylactic Acid) | PET (Polyethylene Terephthalate) |

|---|---|---|

| Environmental Impact | Plant-based, lower carbon footprint | Petroleum-based, higher emissions |

| Toxicity | Safe, no toxic fumes when heated | May release toxins if burned |

| Material Safety | Approved for food contact, no microplastics | Safe but potential microplastic concerns |

| Heat Resistance | Softens at low temperatures, not suitable for high-heat uses | Withstands higher temperatures, more versatile |

| Strength | Stiffer and more brittle | Stronger and more flexible |

| Overall Sustainability | Good for compostable, single-use items | Better suited for closed-loop recycling systems |

Bio-Based

One of the most significant advantages of PLA is that it is made from renewable resources like corn starch and sugarcane. This plant-based origin reduces dependence on petroleum and helps lower greenhouse gas emissions during production. In sustainability-focused industries, this aspect of PLA is seen as a key factor in addressing long-term environmental challenges.

Biodegradable

PLA products meet international biodegradation standards and can naturally decompose into carbon dioxide and water under certain environmental conditions, such as high temperature, humidity, and industrial composting facilities, and do not need to be stored in landfills.

Doesn’t Emit Toxic Fumes

When heated, PLA plastic does not release harmful or toxic fumes. This makes it safer for indoor use, especially in environments like homes, schools, or offices. Unlike petroleum-based plastics such as ABS, which can emit unpleasant odors or potentially hazardous compounds during melting or printing, PLA remains relatively odorless and clean. Its non-toxic behavior contributes to a safer user experience and aligns well with the growing demand for low-emission materials in everyday applications.

What Are the Cons to PLA?

Higher prices

Compared to traditional plastics like PET, PLA plastic tends to be more costly to produce. Although it is derived from renewable resources, the agricultural production, fermentation, and polymerization processes involved in making PLA plastic can increase the overall manufacturing cost. For businesses operating at large scales, this price difference can be a limiting factor when choosing between PLA plastic and conventional plastics.

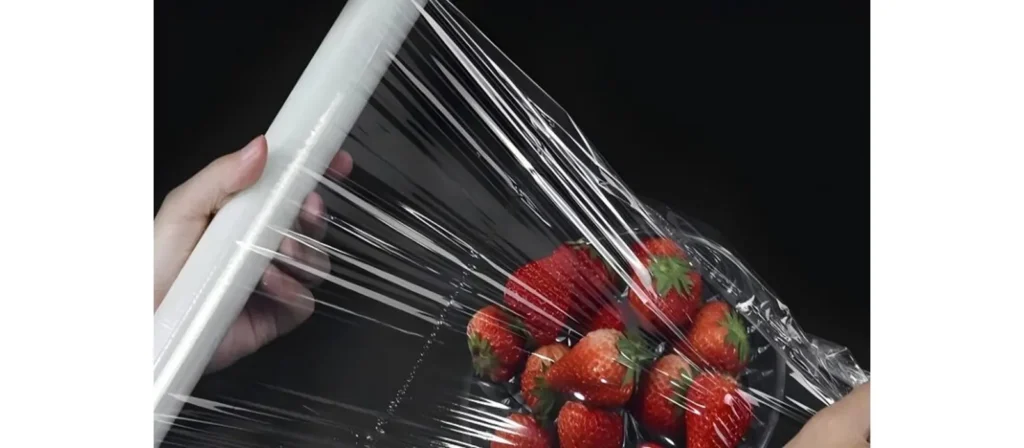

More Permeable

Compared to traditional plastics, PLA plastic is relatively permeable to moisture and gases. Therefore, PLA plastic is generally not suitable for applications requiring extended shelf life or long-term stable barrier properties. While it performs well in short-term, disposable packaging, PLA plastic may not be the best choice for products that require long-term use or storage stability.

Cannot Be Recycled with Other Plastics

Another significant drawback is that PLA plastic cannot be recycled through traditional plastic recycling systems. Mixing PLA plastic with conventional plastics like PET or HDPE can contaminate entire batches of recyclable material, which is why many recycling facilities refuse to accept it. Although PLA recycle technologies do exist, they are not yet widely implemented. This creates challenges for both consumers and waste management systems, especially in regions lacking industrial composting or dedicated PLA plastic filament recycling programs.

Common Uses of PLA Plastic

PLA Plastic for 3D Printer

One of the most popular applications of PLA plastic today is in 3D printing, especially among hobbyists, educators, and professionals. PLA plastic filament is easy to print with due to its low melting point and minimal warping, which makes it ideal for beginners. Brands like Hatchbox PLA are widely used for producing prototypes, educational models, and even artistic sculptures. Since the material is plant-based and emits no harmful fumes during printing, it is also well-suited for indoor environments.

When working with PLA plastic in 3D printing, one important consideration is what to do with 3D print waste. Failed prints, support structures, and scraps made of PLA plastic are not suitable for general recycling. However, some specialized services and PLA plastic filament recycling systems can recover and reuse the material in new filaments.

PLA Coating

PLA coating is commonly used to enhance the surface of paper products, providing a smooth, moisture-resistant, and biodegradable barrier. It is especially useful in cups, bowls, paper straws, food trays, and other disposable packaging that needs to hold liquids or greasy foods without leaking. Unlike traditional plastic coatings, PLA coatings are made of plant-based PLA, offering a more sustainable option for single-use items.

This coating layer not only improves the product’s durability and functionality but also maintains its compostable properties under industrial composting conditions. It plays a key role in making eco-friendly packaging that feels and performs like plastic but aligns with global sustainability goals.

Medical Implants and Devices

PLA is also used in the medical field for temporary implants, surgical sutures, tissue scaffolds, and drug delivery systems. Its biocompatibility and ability to safely degrade in the human body make it a reliable material for applications where the product should naturally disappear after performing its function. These properties have led to its inclusion in several FDA-approved devices.

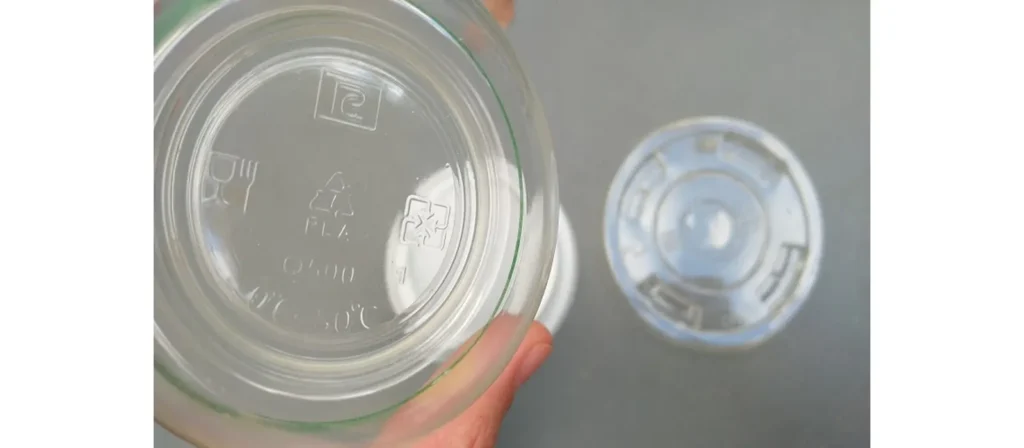

Food and Drink Packaging

PLA is widely used in food and beverage packaging, including cups, lids, takeout containers, and disposable utensils. Many of these items are clearly labeled as made of PLA, helping eco-conscious consumers make informed choices. One of PLA’s advantages in this space is its clean, glossy finish that resembles traditional plastics, making it ideal for branding and product presentation.

Beyond its appearance, PLA packaging is safe for direct food contact and performs well with both hot and cold items. It is odorless and tasteless, ensuring that it does not interfere with the flavor or aroma of the food. As more restaurants, cafes, and catering businesses seek to reduce their environmental footprint, PLA-based packaging is becoming an attractive solution that aligns with both visual standards and sustainability goals.

Fibers (Carpet, Clothing)

PLA can be processed into fibers used in textiles and carpeting. These fibers are known for being lightweight and moisture-resistant. In clothing, PLA blends offer an alternative to polyester with a smaller carbon footprint. In carpets and other nonwoven materials, they provide durability along with environmental benefits during manufacturing and disposal.

Agricultural Films and Seedling Products

In agriculture, PLA plastic is increasingly being adopted as a sustainable alternative to traditional plastic mulch films and nursery products. Items such as seedling trays, plant pots, and crop covers can be manufactured using plant-based PLA plastic, offering both functional performance and environmental advantages. These products naturally degrade after use under the right conditions, reducing residual plastic waste in soil and improving field cleanup efficiency.

Because polylactic acid PLA plastic is made from renewable crops like corn or sugarcane, its use in farming supports a closed-loop model where plant materials return to the soil after serving their purpose. This makes PLA plastic especially suitable for applications where end-of-life management in open environments is difficult. As the agricultural industry looks to reduce reliance on fossil-based films, PLA plastic provides a cleaner and more responsible option.

How to Dispose of PLA Plastic

PLA plastic is considered conditionally compostable, so the best way to dispose of it is through industrial composting facilities. These composting centers operate under high temperatures and humidity, breaking down compostable PLA into water, carbon dioxide, and biomass. If discarded in landfills, oceans, or with other recyclable plastics, PLA plastic will not decompose and may cause the same long-term pollution problems as traditional materials.

Unfortunately, the growing popularity of PLA has also led to concerns around greenwashing. Marketing PLA as a “green” solution without disclosing disposal limitations can mislead consumers. A compostable PLA product that ends up in a landfill will not live up to its promise. Until there is a broader understanding and better infrastructure for PLA composting and recycling, we must remain cautious, realistic, and proactive in how we use and dispose of these materials.

In summary, while PLA plastic offers significant environmental advantages at the production and use stages, proper disposal is key to maintaining its eco-friendly profile. Consumers and businesses should verify local composting or recycling options and ensure that PLA plastic products are handled through the correct waste streams.

The Future of PLA Plastic

As environmental concerns and sustainability mandates continue to shape consumer behavior and industrial policy, the future of PLA plastic looks increasingly promising. What began as a niche bioplastic is now evolving into a key player in the transition away from fossil fuel–based materials.

One of the most significant drivers of this shift is the growing demand for plant based PLA across multiple industries. From packaging and agriculture to medical devices and electronics, manufacturers are exploring ways to integrate PLA plastic into product lines that prioritize lower emissions and renewable inputs. As production technologies become more efficient, economies of scale are expected to reduce costs and expand global availability.

Another important frontier is recycled PLA. Although current infrastructure for PLA recycle remains limited, several companies and research institutions are developing systems to mechanically and chemically recycle PLA plastic, potentially turning it into new resin or monomers. This advancement could significantly reduce waste and enhance circularity in bioplastics.

From a regulatory perspective, many governments around the world have implemented or proposed a plastic straws ban as part of broader efforts to reduce single-use plastic pollution. This movement is not only reshaping consumer expectations but also creating urgent demand for safer, sustainable alternatives. In this context, PLA plastic straws have emerged as a leading solution due to their compostable nature and compatibility with food-safe standards.

Consumer awareness is another factor shaping the future. As more people ask what are PLA materials, and how they differ from conventional plastics, public education and clear labeling will play a crucial role. Transparent communication around disposal, certifications, and compostability will help prevent misuse and reduce the risk of PLA being treated like traditional plastic waste.

In the years to come, we can expect PLA plastic to become more mainstream, more versatile, and more integrated into the global shift toward sustainable materials. However, its success will depend not only on innovation but also on infrastructure, collaboration, and a shared responsibility to manage bioplastics from production to end-of-life.

Conclusion

In short, PLA plastic is compostable, but only under the right industrial conditions. Its environmental advantages depend not just on how it is produced, but also on how it is handled after use.

As a material, PLA plastic offers a thoughtful balance between performance and sustainability. Whether used in 3D printing, packaging, or as a coating for paper-based food containers, PLA continues to replace conventional plastics in applications where both function and eco-friendliness are priorities.

Still, for PLA plastic to reach its full potential, cooperation is needed across the entire chain from manufacturers to consumers to waste processors. Clear labeling, proper disposal infrastructure, and public awareness are key to ensuring this plant-based solution does not become part of the problem.

FAQs

Is PLA plastic better for the environment than traditional plastic?

Yes, but only when disposed of properly. PLA plastic offers a more sustainable alternative due to its renewable origin and compostability, but if sent to landfills or mixed with regular plastics, its environmental benefits may be lost.

How long does plastic take to decompose?

Conventional petroleum-based plastics can take hundreds of years to decompose. In landfills or the ocean, items like plastic bottles, bags, and straws may persist for 400 years or more, contributing to long-term pollution and environmental damage.

How do I know if PLA food packaging is compostable?

Look for third-party certifications such as ASTM D6400, EN 13432, or labels indicating “certified industrial compostable.” These marks confirm that the PLA packaging meets compostability standards and is safe to send to commercial composting facilities.

What impact will the EU SUP Directive have on plastic coatings?

Starting in 2025, the European Union’s Single-Use Plastics Directive will ban non-degradable plastic coatings commonly used in paper cups, trays, and other food packaging. Therefore, PLA coatings and water-based coatings are becoming the preferred choice in Europe.