PLA, short for Polylactic Acid, is a bio-based plastic made from renewable plant resources such as corn starch, sugarcane, or cassava. When used for cups, straws, and food boxes, PLA serves as a sustainable alternative to traditional petroleum-based plastics, offering similar transparency and rigidity while reducing reliance on fossil fuels.

In practical terms, PLA is widely used in cold drink cups, clear lids, disposable straws, and lightweight food packaging because it can be molded, thermoformed, and printed using existing plastic processing equipment. This makes it especially attractive for food service brands seeking environmentally responsible materials without completely redesigning their packaging systems.

As sustainability regulations tighten and consumer awareness grows, understanding what is PLA, how it performs, and where it fits within real-world packaging applications has become essential for businesses choosing materials for cups, straws, and boxes.

Why PLA Matters in Modern Packaging?

In modern food and beverage packaging, material choice is no longer driven by cost and appearance alone. Brands must balance environmental responsibility, regulatory compliance, functional performance, and consumer expectations. PLA has become increasingly relevant in this context because it offers a plant-based alternative that fits within existing packaging systems while responding to sustainability demands.

Environmental and Regulatory Drivers

PLA matters in modern packaging because it addresses two of the most pressing challenges the packaging industry faces today: reducing dependence on fossil fuels and responding to growing environmental and regulatory pressure. Traditional plastics are derived from petroleum and are designed for durability, not disposal. In contrast, PLA offers a renewable, plant-based alternative that aligns better with current sustainability goals without sacrificing functionality.

Performance in Food Service Packaging

From a material perspective, PLA allows brands to maintain the performance characteristics consumers expect from disposable packaging. It can be made clear, rigid, and lightweight, which is why it is commonly used for cold cups, lids, straws, and food boxes. This familiarity helps businesses transition toward more sustainable materials without disrupting product presentation, supply chains, or user experience.

Role in Compostable Packaging Systems

PLA also matters because it fits into the broader shift toward compostable and bio-based packaging systems. Many governments and municipalities are introducing restrictions on conventional plastics while encouraging compostable alternatives. PLA is one of the few materials that can be industrially composted under controlled conditions, making it compatible with certified composting programs and waste management frameworks in many regions.

Consumer Expectations and Brand Signaling

Equally important is consumer perception. Modern consumers increasingly associate packaging choices with brand values. Using PLA signals an effort to reduce environmental impact and adopt forward-looking materials, especially in food service and takeaway settings where single-use packaging is unavoidable. While PLA is not a universal solution, its role in modern packaging lies in bridging the gap between performance, sustainability, and evolving market expectations.

The Origin of PLA: A Bio-based Alternative to Plastic

PLA’s origins lie in biochemistry. Developed as early as the 1930s, it wasn’t commercially viable until modern fermentation and polymerization processes were refined in the late 20th century. Companies like NatureWorks LLC began scaling PLA production around 2002, and since then, global demand has surged, driven by eco-conscious industries.

Unlike polyethylene (PE) or polypropylene (PP), PLA isn’t extracted from fossil fuels. Instead, it’s produced using sugars fermented by specific bacteria into lactic acid, which is then processed into polylactic acid. This makes it one of the first widely available bioplastics with commercial-scale production potential and food-safe applications.

Today, PLA is commonly certified as compostable by standards such as EN 13432 (Europe) and ASTM D6400 (USA), making it a legitimate solution for packaging waste reduction.

What Is PLA Made Of?

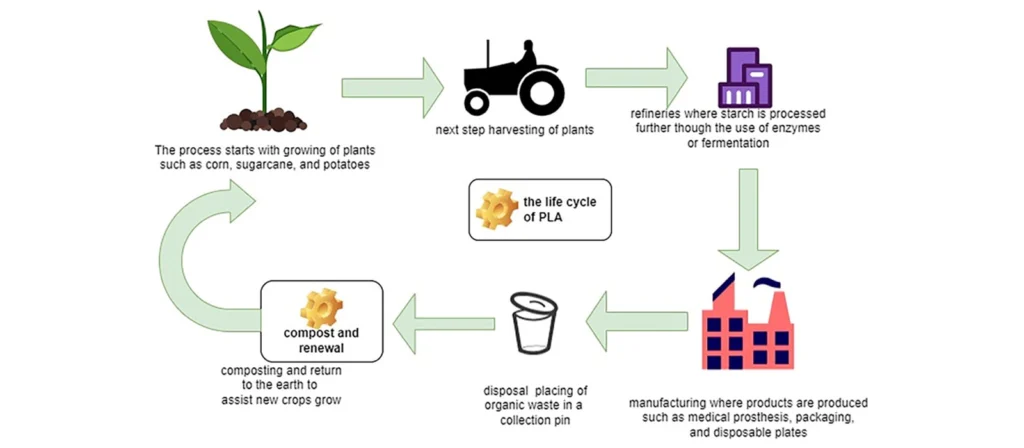

PLA is made by converting plant-derived sugars into lactic acid through fermentation, then polymerizing that lactic acid into a solid bioplastic resin. The process starts with renewable crops such as corn or sugarcane and ends with PLA pellets that can be shaped into cups, straws, and food boxes using standard plastic manufacturing methods.

Raw Materials: Corn, Sugarcane, and Other Starch-rich Crops

The journey of PLA begins with natural, renewable resources, primarily crops rich in starch. The most commonly used raw material is corn, especially in the United States, while sugarcane and cassava are popular in Asia and South America. These crops serve as the base because they contain high levels of glucose or sucrose, which are essential sugars used in the fermentation process.

The advantage of using these crops lies in their availability and renewability. Unlike petroleum, which is finite and geopolitically sensitive, agricultural feedstocks can be replanted annually. While concerns about food vs. fuel or land use exist, current PLA production represents a tiny fraction of global agricultural capacity.

This agricultural origin also plays a key role in reducing carbon footprint. PLA absorbs carbon dioxide during crop growth and releases less CO₂ during degradation or incineration than petroleum-based plastics. According to industry data, the carbon emissions from PLA production are up to 75% lower than those from traditional plastics.

The Fermentation Process: Converting Sugars into Lactic Acid

Once harvested, the starch-rich crops undergo milling and enzymatic hydrolysis to break down complex carbohydrates into simple sugars like glucose. This sugary solution is then subjected to a fermentation process using specialized bacterial strains(usually Lactobacillus species).

During fermentation, these bacteria convert sugars into lactic acid, the key building block of PLA. The process is similar to how yogurt or kimchi is made but optimized in industrial bioreactors under controlled temperature and pH conditions.

This stage is eco-efficient and non-toxic, producing no hazardous by-products. Lactic acid production also has relatively low water and energy demands compared to petroleum refining, positioning PLA as a more sustainable alternative even from the early stages.

Polymerization: How Lactic Acid Becomes PLA

Lactic acid alone isn’t useful as a plastic—it must be converted into polylactic acid, the high molecular weight polymer with plastic-like properties. This is done through two primary polymerization methods:

- Direct Condensation Polymerization

A simpler method but typically results in low-molecular-weight PLA, suitable for low-performance applications. - Ring-Opening Polymerization of Lactide

This is the preferred industrial method. Lactic acid is first converted into lactide (a cyclic dimer), which is then polymerized in the presence of metal catalysts to form high-quality PLA suitable for packaging.

The end result is PLA resin pellets, which can be processed using existing plastic manufacturing machinery—another factor that aids its adoption by packaging companies like us at Million Pack.

Environmental Advantages of the PLA Production Process

Compared to fossil-based plastics, the PLA production process is considerably more sustainable. Key environmental benefits include:

- Lower Greenhouse Gas Emissions: As mentioned earlier, PLA emits up to 75% fewer greenhouse gases during production.

- Reduced Energy Consumption: PLA production typically requires 50% less energy than traditional plastic manufacturing.

- Compostability: End-of-life disposal is more manageable, especially in regions with commercial composting facilities.

- No Toxic Byproducts: From raw material to end product, no harmful substances are released into the environment.

These factors make PLA not just a temporary alternative but a viable long-term strategy for companies seeking sustainable packaging solutions.

Key Properties That Make PLA Suitable for Food Use

PLA possesses a set of characteristics that make it ideal for disposable food packaging:

- Biodegradability: Under industrial composting conditions, PLA can degrade into CO₂ and water in under 90 days.

- Food Safety: PLA is non-toxic and safe for direct food contact. It does not leach harmful chemicals, making it suitable for packaging beverages and edibles.

- Transparency: It has a similar clarity to PET, which is useful for showcasing food and drink products.

- Moldability: PLA can be thermoformed, injection molded, or extruded, allowing manufacturers to produce various shapes from cups to trays.

- Grease and Oil Resistance: Essential for hot food packaging like burgers or soup containers.

These features collectively explain why PLA is becoming the go-to solution in sustainable packaging across coffee shops, restaurants, and catering services.

Food Safety: Is PLA Really Safe for Hot Drinks and Food?

PLA is generally recognized as safe (GRAS) by major regulatory bodies, including the U.S. FDA and the European Food Safety Authority (EFSA). It meets food-grade safety standards when properly produced and tested, especially concerning:

- No BPA or phthalates

- Non-toxic at high temperatures (up to 50–60°C for standard PLA)

- No harmful leaching into food or drinks

However, it’s important to distinguish between standard PLA and heat-resistant PLA (known as CPLA). While regular PLA can deform above 50°C, CPLA can withstand temperatures up to 90°C, making it suitable for hot drinks or microwavable containers.

We ensure all PLA products at Million Pack carry SGS and TÜV food-grade certifications and comply with ISO 22000 food safety standards, ensuring our customers can trust them for safe usage in real-world conditions.

PLA vs Traditional Plastics: Performance, Safety, Cost

PLA differs from traditional plastics primarily in raw material source, environmental impact, and end-of-life behavior. While conventional plastics such as PET, PP, and PS are derived from fossil fuels and designed for long-term durability, PLA is made from renewable plant-based resources and intended for shorter lifecycle applications like disposable food packaging.

Mechanical Performance: Is PLA Strong Enough?

When evaluating what PLA is as a replacement for traditional plastics, performance is a crucial factor. PLA’s strength lies in its rigidity and dimensional stability. It performs well in structural applications like disposable cups, salad boxes, and clamshell containers. However, it has lower flexibility and impact resistance compared to petroleum-based plastics like polypropylene (PP) or polyethylene terephthalate (PET).

PLA is best suited for low to moderate mechanical stress conditions. For example:

- Hot beverage cups may require PLA lining but not be ideal for microwave use.

- PLA straws maintain shape but can soften in very hot drinks.

- Boxes and trays made with PLA or PLA coatings are ideal for cold or room-temperature foods.

Manufacturers can improve PLA’s performance through blending with other biodegradable polymers or adding reinforcing agents, but that may affect compostability. Overall, while PLA may not completely replace all plastics, it excels in single-use food packaging where strength-to-weight ratio and sustainability are key.

Cost comparison: PLA vs. PP, PET, and PS plastics

In terms of cost, PLA is still more expensive than traditional plastics on a per-ton basis. Prices vary depending on global corn and sugar markets, production scale, and processing additives. Currently, PLA costs range from $1.50 to $2.00 per kg, compared to PP or PET which can cost as little as $1.00 per kg or less.

However, the cost gap is narrowing as PLA production scales globally and as more governments impose taxes or bans on conventional plastic products. Additionally, when factoring in:

- Disposal fees

- Environmental penalties

- Brand value for sustainability

PLA (polylactic acid) is more competitive in terms of total cost of ownership. For many businesses, especially those in Europe and North America, using PLA is no longer just a matter of ethical considerations, but also of regulatory and financial considerations.

Biodegradability and Composting

PLA is industrially compostable, meaning it breaks down into carbon dioxide, water, and organic matter within 60–90 days under commercial composting conditions (high heat, moisture, and microbial activity). It complies with international standards like:

- EN 13432 (EU)

- ASTM D6400 (USA)

However, in home composting or landfill conditions, PLA breaks down much more slowly, sometimes over several years. This leads to some confusion or criticism, which is why clear labeling and consumer education are crucial. At Million Pack, we always inform our partners that PLA packaging requires proper disposal channels if its environmental benefits are to be fully realized.

PLA vs Traditional Plastics: At-a-Glance Comparison

| Feature | PLA (Polylactic Acid) | PP (Polypropylene) | PET (Polyethylene Terephthalate) | PS (Polystyrene) |

|---|---|---|---|---|

| Source | Renewable (corn, sugarcane) | Petroleum-based | Petroleum-based | Petroleum-based |

| Biodegradability | Compostable (industrial only) | Not biodegradable | Not biodegradable | Not biodegradable |

| Food Safety | Food-safe, BPA-free | Food-safe | Food-safe | Food-safe but may leach styrene |

| Heat Resistance | ~60°C (PLA), ~90°C (CPLA) | Up to 130°C | Up to 120°C | Up to 100°C |

| Transparency | High (similar to PET) | Opaque | High | High |

| Strength & Durability | Moderate rigidity | High toughness | High strength | Brittle |

| End-of-Life | Compostable (with facility) | Landfill/incineration | Recyclable (widely) | Difficult to recycle |

| Cost per kg (approx.) | $1.50–2.00 | $1.00 or less | ~$1.00 | <$1.00 |

| Environmental Impact | Low carbon footprint | High carbon footprint | Moderate carbon footprint | High carbon footprint |

PLA in Food Packaging: Cups, Straws, Boxes, Trays

PLA is widely used in food packaging applications such as cups, straws, boxes, and trays because it offers a combination of clarity, rigidity, and processability suitable for single-use items. Its plant-based origin and compatibility with standard manufacturing methods make PLA a practical alternative to conventional plastics in cold and room-temperature food service environments.

PLA Cups

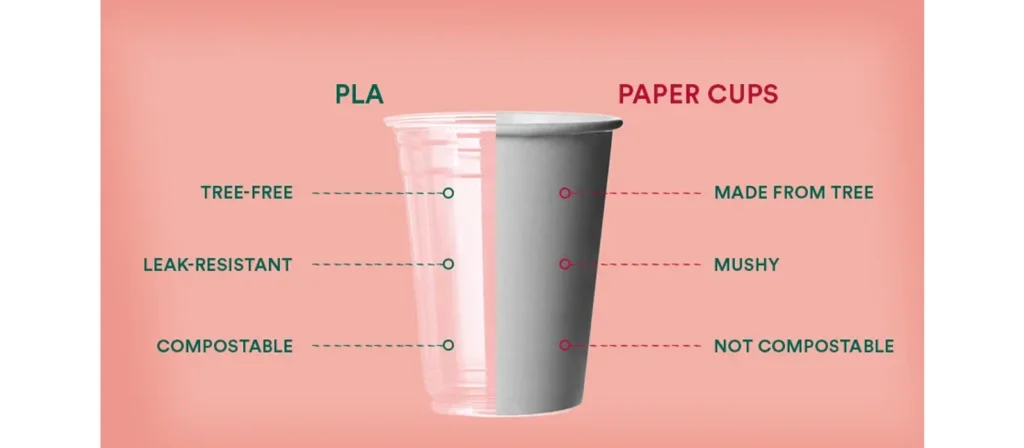

One of the most widespread applications of PLA in food packaging is in the production of disposable cups. PLA can be used either as the main material for clear cold drink cups or as a lining in paper-based hot drink cups.

For cold applications, PLA’s transparency and gloss make it an excellent alternative to PET. It offers a clean, high-end look for beverages such as iced coffee, smoothies, and fruit juices. These cups are fully compostable and can be labeled accordingly, helping businesses meet eco-friendly goals and impress sustainability-conscious consumers.

For hot drinks, CPLA (crystalized PLA) is used because of its heat resistance. While standard PLA softens at 50–60°C, CPLA withstands up to 90°C. At Million Pack, we provide double-wall hot cups with CPLA linings and lids, ensuring both performance and compostability.

These cups are also ideal for companies wanting to move away from PE-coated paper cups, which cannot be composted or easily recycled.

PLA Straws

Plastic straws are among the top items banned in many countries due to their environmental impact. PLA straws offer a perfect compostable alternative without sacrificing user experience. Unlike paper straws, which often become soggy, PLA straws retain their rigidity and are tasteless and odor-free.

They can be used for cold beverages, juices, cocktails, and bubble tea. While standard PLA straws are not suitable for high-heat drinks, new CPLA straw formulations can handle warmer conditions, expanding their usability.

PLA straws decompose in industrial composting settings without leaving toxic residue, making them compliant with EU single-use plastic bans and local regulations in California, Canada, and Australia.

For food businesses, using PLA straws also allows you to offer “plastic-free” solutions that are both practical and environmentally responsible, aligning your brand with sustainable values.

PLA-coated Paper Boxes

Traditional paper food boxes are often lined with polyethylene (PE) to prevent leaks, making them non-compostable and difficult to recycle. By contrast, PLA-coated paper boxes are fully compostable under industrial conditions, including both the fiber and the liner.

PLA coatings are effective at resisting:

- Grease and oil

- Water and moisture

- Temperature variations (especially with heat-sealed lids)

This makes them ideal for:

- Salads

- Rice or pasta dishes

- Burgers and wraps

- Fried or saucy foods

Our line of PLA-lined menu boxes, hamburger boxes, and wrap boxes offers a clean solution for restaurants, food trucks, and catering services looking to meet sustainability targets without sacrificing quality.

PLA Trays and Lids

Trays are essential in food presentation and storage, especially for sushi, desserts, and cold items. PLA trays combine high clarity with biodegradability, offering a premium feel while still aligning with compostable standards.

Features of PLA trays and lids:

- Crystal-clear presentation for showcasing food items

- Heat-sealable properties for freshness and hygiene

- Excellent stackability and rigidity for delivery and takeout

Common applications include:

- Sushi trays with PLA lids

- Bakery and dessert packaging

- Salad bowls with CPLA lids

As a manufacturer, we ensure that PLA trays meet SGS food-grade certifications, and they integrate well into standard packaging lines, making them easy to adopt for existing businesses.

FAQs

- Is PLA plastic compostable?

PLA is compostable under industrial composting conditions where controlled heat, moisture, and microorganisms are present. It does not break down effectively in home composting or natural environments. - When should businesses choose PLA packaging?

PLA is a good choice for single-use food packaging where sustainability goals, regulatory compliance, and use with cold or room-temperature foods are key considerations. - How long does PLA take to biodegrade?

Under industrial composting conditions, PLA typically breaks down within several months, depending on temperature, humidity, and microbial activity. In non industrial environments, such as landfills or natural settings, PLA degrades much more slowly and may persist for years. Proper disposal is essential to achieve its intended environmental benefits. - Is PLA food packaging banned in Europe?

PLA food packaging is not banned in Europe. However, under the EU Single-Use Plastics Directive, certain single-use items such as cutlery, plates, and straws are prohibited regardless of whether they are made from conventional plastic or PLA.

Conclusion

Understanding what is PLA and how it compares to traditional plastics is essential for any business aiming to move toward sustainable packaging. As we’ve explored, PLA offers a unique combination of renewability, food safety, biodegradability, and functional performance that makes it an ideal material for cups, straws, boxes, and trays.

While PLA does come with certain limitations, such as composting infrastructure and slightly higher costs, these challenges are increasingly outweighed by its long-term environmental and regulatory benefits. For food businesses, caterers, cafes, and packaging wholesalers, PLA is not just a “green” alternative; it’s a future-proof solution.

At Million Pack, we are proud to be at the forefront of this transition. With advanced manufacturing capabilities and a global export network, we offer a wide range of PLA-based food packaging products that meet international food safety and compostability standards. With Million Pack, you’re choosing a packaging partner who’s as committed to quality and sustainability as you are.