Making a strong first impression often starts with your packaging. Whether on a retail shelf or in a customer’s hands, the appearance of your packaging reflects your brand’s attention to detail. But even the most well-designed graphics can fall flat if the surface finish lacks protection or polish. That’s where packaging coatings make all the difference, adding visual depth, tactile quality, and a layer of durability that preserves your design through shipping, shelf life, and handling.

Aqueous coating is a fast-drying, water-based protective topcoat applied inline to packaging surfaces during production. It seals printed graphics, resists fingerprints and scuffs, enhances color presentation, and offers selectable gloss, satin, or matte finishes. Because it is low-odor and low-VOC, it supports food-contact packaging and aligns with sustainability goals better than many solvent-based or film-lamination alternatives. It also speeds up handling and finishing, reducing defects like set-off and rework. For folding cartons, retail boxes, and branded sleeves, aqueous coating delivers cleaner results, faster turnarounds, and consistent visual quality across every unit.

Next, I’ll unpack how Aqueous Coating works, where it excels, when to choose it over UV or lamination, and practical tips to optimize paper, design, and production outcomes.

What is Aqueous Coating?

Aqueous coating is a water-based surface treatment applied to printed packaging materials to improve their appearance, durability, and resistance to handling damage. It creates a transparent, uniform layer that enhances surface performance without altering the structural properties of the substrate.

Formulated primarily with water, acrylic polymers, and performance additives, aqueous coatings are free from harmful solvents and contain low levels of volatile organic compounds (VOCs). This makes them suitable for environmentally sensitive applications, including food-contact packaging. The chemical composition also ensures excellent adhesion, flexibility, and compatibility with a wide range of coated paperboard and folding carton stocks.

Physically, aqueous coatings are fast-drying, odorless, and available in multiple finish options such as gloss, matte, satin, and soft-touch. They offer surface protection against fingerprints, scuffs, and minor abrasion while elevating the visual impact of printed graphics. Depending on the chosen finish, the coating can either enhance color vibrancy or add a subdued, elegant look that supports premium branding.

What is the Process of Aqueous Coating?

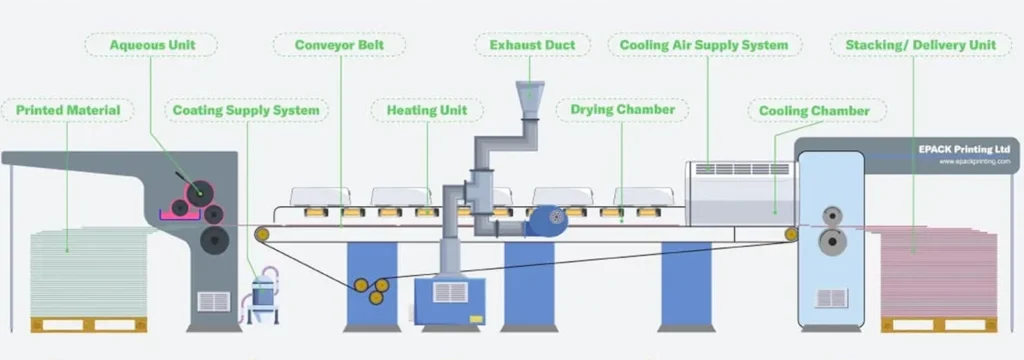

The application of aqueous coating follows a controlled production sequence designed to ensure uniform coverage and rapid curing. Though the chemistry behind the process is complex, its operation in packaging lines can be summarized in three essential stages: coating, drying, and curing.

Application

Aqueous coating is applied inline, immediately after the ink is printed on the packaging sheet. Using a roller or blanket unit, the coating is spread as a thin, even layer across the surface, covering the printed areas without smearing the ink.

Drying

Once applied, the coated sheet moves through a heated air drying system. The water in the coating formula evaporates quickly, which significantly speeds up the drying process compared to traditional solvent-based coatings.

Curing and Readiness

As the coating dries, it forms a smooth, transparent film that seals the printed surface. This cured layer offers immediate protection against scuffing, fingerprints, and minor moisture, allowing the sheets to move directly into finishing steps like die-cutting and folding without extra wait time.

Aqueous Coating Types

Aqueous coating is available in a variety of finishes, each designed to enhance the look, feel, and performance of printed materials in different ways. Understanding the available types can help you choose the right coating to meet your specific print and branding goals.

Gloss Aqueous Coating

Gloss aqueous coating provides a high-shine, reflective surface that intensifies color and detail. It is often used for photo-rich prints, promotional flyers, and product packaging where visual impact is key. While it creates a vibrant appearance, it may show fingerprints more easily on high-touch items.

Matte Aqueous Coating

Matte aqueous coating offers a flat, glare-free finish that enhances readability and lends a refined, understated look to print materials. It is ideal for professional reports, text-heavy documents, and minimalist design styles. The smooth surface resists scuffs while maintaining a natural feel.

Satin Aqueous Coating

Satin aqueous coating, sometimes called silk finish, falls between gloss and matte. It provides a soft sheen that subtly enhances colors without overwhelming the design. It is commonly used for brochures, corporate presentations, and packaging that require both elegance and durability.

Soft-Touch Aqueous Coating

Soft-touch aqueous coating delivers a velvety, luxurious texture that stands out immediately to the touch. It is widely used in high-end branding, luxury packaging, and special edition marketing materials. While it adds sophistication, it can be more costly than other coating types.

Dry-Erase Aqueous Coating

Dry-erase aqueous coating creates a surface that can be written on and wiped clean using dry-erase markers. It is useful for reusable materials such as calendars, checklists, training boards, and planners. This functional finish adds interactivity to otherwise static print pieces.

Textured Aqueous Coating

Textured aqueous coating mimics surface patterns such as linen, brushed metal, or leather to enhance tactile experience. This option is often used in packaging, invitations, and promotional materials where texture adds perceived value and uniqueness without the need for specialty substrates.

Each type of aqueous coating serves a different purpose, from amplifying visual impact to adding functionality or luxury. Choosing the right finish ensures your printed materials align with your brand identity and audience expectations.

Using Aqueous Coating in Food and Beverage Packaging

In food and beverage packaging, surface quality is more than just an aesthetic concern. It affects consumer perception, product hygiene, and regulatory compliance. Aqueous coating provides a fast-drying, water-based finish that protects printed surfaces from handling damage while supporting food safety standards and sustainability goals.

Common applications of aqueous coating in food and beverage packaging include:

- Folding cartons for dry food, snacks, frozen meals, and confectionery

- Beverage carriers and multipacks requiring moisture resistance and shelf appeal

- Sleeves for cups, bottles, and trays used in both retail and quick-serve environments

- Takeout and delivery boxes that demand grease resistance and clean branding

- Liners and inserts for food-contact inner packaging

- Retail-ready packaging for shelf-stable grocery and refrigerated goods

Aqueous coating creates a protective layer that resists scuffs, fingerprints, and minor moisture exposure, helping the packaging maintain a clean, consistent appearance from production to point of sale. It supports gloss, matte, satin, and soft-touch finishes to align with brand aesthetics across fast-moving consumer goods.

Critically, its low-VOC, low-odor formulation makes it suitable for indirect food-contact surfaces and environmentally sensitive production lines. Since it does not compromise recyclability, it is increasingly used by brands transitioning to more sustainable paper-based packaging.

What Are the Benefits of Aqueous Coating?

Aqueous coating offers a powerful combination of aesthetic enhancement, functional protection, and environmental responsibility. Its benefits make it one of the most widely used finishing techniques in commercial printing and packaging, especially for brands that prioritize both performance and presentation.

Enhanced Visual Appeal

One of the most immediate advantages of aqueous coating is its ability to improve the visual quality of printed materials. Whether in gloss, matte, satin, or soft-touch finish, it adds depth to colors, sharpens image clarity, and gives your packaging a professional, high-quality appearance. A well-coated print surface reflects attention to detail and elevates the perceived value of your product.

Surface Protection

Aqueous coating serves as a durable shield against common forms of wear and tear. It reduces the likelihood of scratches, scuffs, fingerprints, and smudges that can diminish the appeal of printed materials over time. In packaging, this is particularly important as products move through storage, transport, and retail handling environments.

Quick Drying Time

Unlike traditional varnishes or solvent-based coatings, aqueous coatings dry quickly, often inline during the printing process. This speeds up production timelines and reduces the risk of set-off (ink transfer between sheets), making the process more efficient and cost-effective.

Eco-Friendly and Non-Toxic

Because it is water-based and free from volatile organic compounds (VOCs), aqueous coating is one of the most environmentally responsible finishing options available. It meets the growing demand for sustainable packaging and printing practices, making it a preferred choice for companies looking to reduce their ecological footprint.

Cost-Effective for Large Runs

For high-volume print and packaging jobs, aqueous coating provides excellent value. It is more affordable than many specialty coatings like UV or lamination, especially when applied inline during the offset printing process. The reduced need for additional drying time or equipment also helps cut costs without compromising on quality.

Compatible with Post-Processing

Unlike some other finishes, aqueous coating is compatible with a variety of post-print techniques such as die-cutting, embossing, and foil stamping. It doesn’t crack or peel during folding and handling, allowing for greater flexibility in design and production without sacrificing durability or aesthetics.

In summary, aqueous coating delivers across the board, from vibrant, market-ready visuals to resilient, eco-conscious protection. Whether your goal is to impress customers, extend shelf life, or streamline your print operations, the benefits of aqueous coating make it an intelligent and future-ready finishing choice.

What is the Difference Between Aqueous and UV Coating?

When selecting a surface finish for packaging or printed materials, aqueous coating and UV coating are two widely used options. Both enhance durability and visual appeal, but they differ in several key areas, including composition, application method, visual characteristics, and environmental impact.

The table below summarizes the primary differences:

| Aspect | Aqueous Coating | UV Coating |

|---|---|---|

| Composition | Water-based with acrylic polymers | Solvent-free, cured by ultraviolet light |

| Application Method | Applied inline during offset printing, dries with heated air | Applied inline or offline, cures instantly under UV light |

| Finish Options | Gloss, matte, satin, soft-touch | Mostly high-gloss, some matte options available |

| Durability | Good resistance to scuffing, moisture, and fingerprints | Very high durability and hardness, but may crack under folding |

| Visual Impact | Subtle, elegant, less reflective | Very high gloss and clarity, enhances color saturation |

| Eco-Friendliness | Low-VOC, recyclable, food-packaging compatible | Harder to recycle, may contain trace chemicals, not food-contact safe |

| Production Speed | Fast drying, good for high-speed packaging lines | Instant curing, but requires UV lamps and precise handling |

| Cost Consideration | More economical for large volumes | Higher material and equipment costs |

| Ideal Use Cases | Folding cartons, food and beverage packaging, cosmetic boxes | Postcards, book covers, promotional pieces with heavy handling |

In summary, aqueous coating offers greater flexibility for sustainable, food-safe, and cost-effective packaging applications. UV coating, while more visually intense and abrasion-resistant, is better suited to specialty prints where gloss and durability take priority over recyclability or regulatory compliance.

Frequently Asked Questions About Aqueous Coating

Is aqueous coating eco-friendly?

Yes, aqueous coating is one of the most environmentally friendly print finishes available. It’s water-based, contains little to no VOCs (volatile organic compounds), and is completely non-toxic. It also supports recycling, making it a sustainable choice for businesses focused on eco-conscious printing and packaging.

Can aqueous coating be written on?

It depends on the type of aqueous coating used. Gloss and satin finishes typically repel ink and are not ideal for writing. However, some matte or specially formulated writable aqueous coatings allow for ballpoint pen or pencil use. Always test your specific coating and paper combination before final production.

Does aqueous coating affect color accuracy in printing?

Aqueous coating can slightly enhance color vibrancy, particularly with gloss finishes. However, it generally does not distort or alter the ink’s color balance. In fact, it protects the ink layer beneath from fading and damage, helping to preserve the intended design and colors over time.

Is aqueous coating waterproof?

No, aqueous coating is not fully waterproof, but it does offer limited moisture resistance. It protects against light splashes, humidity, and handling-related dampness. For applications requiring full water resistance, UV coating or lamination would be better options.

How does aqueous coating compare to lamination?

Aqueous coating is applied as a liquid and dries quickly, while lamination involves bonding a plastic film to the surface of the printed material. Lamination is thicker and offers more durability, but it’s also more expensive and less eco-friendly. Aqueous coating provides solid protection and visual enhancement without the bulk or added cost of lamination.

Partnering with Million Pack: The Ideal Choice for Enhancing Packaging and Protection

As this guide illustrates, selecting the right finish is a critical step in enhancing your packaging and protection. But achieving that perfect balance of visual appeal, durability, and sustainability isn’t just about choosing a coating—it’s about choosing the right partner to execute your vision flawlessly.

This is why partnering with Million Pack is the ideal choice. We don’t just supply packaging; we provide comprehensive solutions. Our team of experts collaborates with you to navigate the complexities of finishes, from eco-friendly aqueous coatings to specialty textures. We ensure that the final result not only protects your product through handling and shipping but also elevates your brand identity on the shelf. Choose Million Pack, and let’s create packaging that makes a lasting first impression.