Bamboo packaging is increasingly regarded as the future of eco-friendly product design because it offers a rare balance of renewability, functional performance, and environmental responsibility. As a fast-growing natural resource, bamboo can be harvested without long-term ecological damage, making it a strong alternative to traditional packaging materials that rely on finite resources or energy-intensive processes.

As sustainability expectations continue to rise, brands are facing greater pressure from environmental regulations, consumer awareness, and global plastic reduction initiatives. Packaging is no longer judged solely on cost or appearance. It is now evaluated by its full lifecycle impact, including sourcing, production, usage, and end-of-life disposal. These factors have reshaped how companies approach eco-friendly product design across multiple industries.

Bamboo packaging responds directly to these challenges by combining structural strength, lightweight properties, and natural aesthetics with a significantly lower environmental footprint. Its versatility allows it to be used in a wide range of packaging formats, while its renewable nature supports long-term sustainability goals without compromising design flexibility or product protection.

This article explains why bamboo packaging is gaining global attention and how it is shaping the future of eco-friendly product design, from material selection and functional performance to environmental impact and market adoption.

What is Bamboo Packaging?

Bamboo packaging refers to packaging materials made from bamboo (a fast‑growing grass species, not a conventional tree) or bamboo‑based fibres and composites, used to create containers, boxes, trays, cutlery, sleeves, shells and other protective or display packaging solutions. Rather than relying solely on plastics, synthetic polymers or timber‐derived pulp, bamboo packaging utilises the plant’s natural fibre strength, renewability and biodegradability to deliver functional packaging that aligns with sustainable product design goals.

Specifically, bamboo packaging may take many forms: moulded pulp products derived from bamboo fibres, laminated bamboo boards, solid bamboo veneers used as decorative packaging elements, or hybrid designs combining bamboo fibre with other eco‑materials.

Bamboo Packaging vs Traditional Packaging

| Feature | Bamboo Packaging | Traditional Packaging (Plastic, Foam, Paper) |

|---|---|---|

| Material Source | Renewable (fast-growing bamboo) | Non-renewable (petroleum, slow-growing trees) |

| Biodegradability | 100% biodegradable in months | Plastic: 500+ years, Foam: 100+ years |

| Recyclability | Easily recyclable and compostable | Limited (plastic and foam rarely recycled) |

| Strength & Durability | High tensile strength, moisture resistant | Varies: Plastic is durable, paper is weak |

| Toxicity | Non-toxic, chemical-free processing | Often contains harmful dyes and resins |

| Production Footprint | Low energy and water usage | High energy consumption and emissions |

| Visual Aesthetic | Natural, elegant, premium appeal | Synthetic, industrial appearance |

| Cost Efficiency (Long-Term) | Increasingly affordable with scale | Often cheaper upfront but costlier long-term |

Why is Bamboo Packaging Sustainable?

Sustainability is not a single attribute but a multi‑faceted concept covering renewability, resource efficiency, environmental impact, end‑of‑life behaviour, and supply chain ethics. Below, we break down the specific attributes that make bamboo one of the most sustainable packaging materials available today.

1. Growth Rate

Bamboo is one of the fastest-growing plants on Earth. Certain species, such as Moso bamboo, can grow up to 91 cm (35 inches) in a single day under optimal conditions.

This rapid growth allows for more frequent harvesting compared to trees used in paper and wood packaging, which can take 10 to 20 years to mature. A mature bamboo plant can be harvested every 3 to 5 years without killing the root system, making it a genuinely renewable resource.

2. Environmental benefits

Bamboo packaging confers a range of environmental benefits that reinforce its sustainability credentials. For example:

- Bamboo can sequester more carbon dioxide and produce more oxygen than many traditional tree species. According to scientific studies, bamboo absorbs up to 12 tons of CO₂ per hectare per year and releases 35% more oxygen into the atmosphere compared to similar-sized tree populations.

- The root system of bamboo helps stabilize soil, reducing erosion, and can thrive on degraded soils that may not be suited for other crops.

- Because bamboo often requires little to no fertilizer or pesticide, cultivation has a lower chemical input burden and thus lesser impact on surrounding ecosystems.

- Bamboo cultivation typically requires fewer inputs.

3. Biodegradability

An essential aspect of sustainability is how a material behaves at end‑of‑life. Bamboo packaging shines here in many respects. Bamboo‑based packaging materials are typically biodegradable and compostable under appropriate conditions.

4. Recyclability

Bamboo-based packaging, especially when created from bamboo pulp or molded fiber, is fully recyclable within standard paper recycling systems.

Bamboo fibers can be reused multiple times without significant degradation in quality. This allows brands to extend the lifecycle of their packaging materials, reducing both the need for virgin resources and the cost of waste disposal.

Advantages and Disadvantages of Bamboo Packaging

Every packaging material has pros and cons. Bamboo, while widely praised, is not without limitations.

Advantages of Bamboo Packaging

- Sustainability

Bamboo grows rapidly, requires minimal water and no chemical fertilizers, making it one of the most renewable packaging materials available. - Customer appeal

Its natural texture and eco-friendly story enhance product perception and brand image, especially among environmentally conscious consumers. - Durability

Bamboo offers strong fiber structure, making packaging more resistant to crushing, bending, and damage during transport. - Antibacterial

Naturally resists bacteria and mold, making it ideal for food, skincare, and hygiene-related packaging. - Extended food shelf life

Its breathable yet durable structure helps protect contents and can maintain freshness longer than some plastics or paper. - Odor absorption

Bamboo absorbs and neutralizes unwanted smells, which helps preserve product aroma and overall cleanliness.

Disadvantages of Bamboo Packaging

- Land Use Risk

Large-scale bamboo farming, if poorly managed, may threaten biodiversity or cause soil depletion. - Cost Issues

Bamboo packaging often costs more than plastic or cardboard due to limited manufacturing scale and higher production complexity. - Transportation Impact

As bamboo is mainly grown in Asia, international shipping increases its carbon footprint, reducing some environmental benefits.

How is Bamboo Food Packaging Made?

Bamboo packaging begins with a plant that is as remarkable as it is resilient. Bamboo can grow up to three feet a day, requires no pesticides, and regrows after harvest without the need for replanting. This makes it an ideal raw material for packaging, particularly when sustainability and scalability are critical.

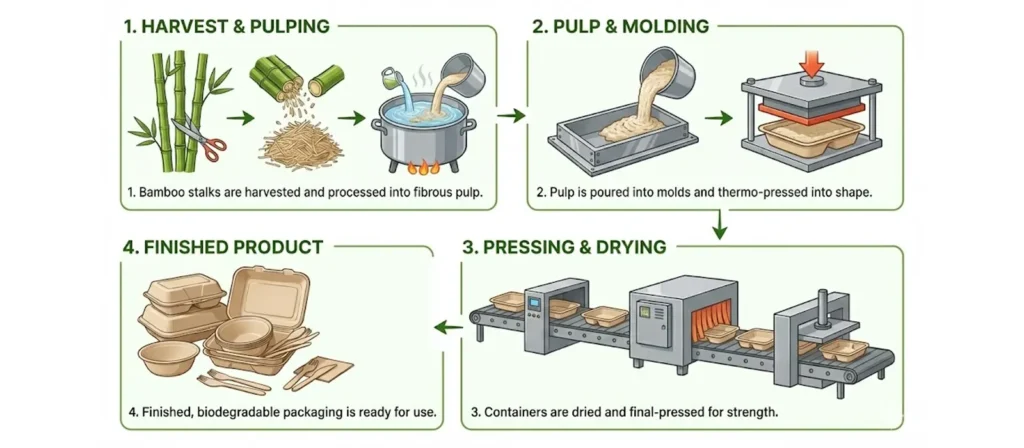

Step 1: Harvesting and Sourcing

Bamboo used in packaging typically comes from controlled plantations. It’s harvested once mature—generally around 3 to 5 years old. Mature stalks are selected for their strength and fiber density.

Step 2: Processing into Pulp or Fiber

For many food applications, bamboo is turned into a pulp, similar to paper or plant-fiber packaging.

- Pulping

The bamboo chips are cooked under controlled temperature and pressure, often with chemicals that help break down lignin and separate fibers. This produces a fibrous pulp. - Washing and screening

The pulp is washed to remove residual chemicals and screened to remove oversized particles, ensuring a more consistent fiber size. - Forming and molding

The bamboo pulp is mixed with water and sometimes small amounts of additives, then deposited onto molds using vacuum suction or pressing.

Different tools and molds create different shapes: plates, bowls, takeaway containers, cup lids, protective trays, and more. - Pressing and drying

The molded pieces are compressed and dried under heat. This step defines the final strength, thickness, and surface quality of the Bamboo Packaging. Higher pressure and well-controlled moisture levels create denser, stronger parts.

Step 3: Molding or Forming

For disposable food containers, bamboo pulp is poured into heated molds that shape it into trays, boxes, or bowls. These molds press the pulp at high temperatures and pressure, creating packaging that is strong, lightweight, and thermally resistant.

Step 4: Drying and Curing

Once molded, the bamboo packaging is dried in industrial dryers. This prevents warping and ensures the structure holds during transportation and usage. In some cases, a natural coating—such as a food-safe wax—is applied to enhance water resistance.

Step 5: Finishing and Quality Control

Final steps include trimming, polishing, and sometimes branding. Quality control checks for structural integrity, food safety compliance, and consistency in finish.

Step 6: Safety and Compliance

Legitimate manufacturers ensure their bamboo food packaging is compliant with global standards such as FDA, LFGB, and BfR. These certifications guarantee that the material doesn’t leach harmful chemicals and is safe for direct food contact.

How Bamboo Packaging Decomposes?

Understanding the decomposition process of bamboo packaging helps businesses and consumers make informed sustainability choices. While bamboo is known for its biodegradability, how it breaks down depends on several factors, including packaging form, environmental conditions, and material treatments.

Bamboo packaging decomposes through natural microbial activity, where fungi, bacteria, and other organisms break down the organic material into carbon dioxide, water, and biomass. This process mimics how plant material naturally decays in the wild but can vary significantly depending on the context.

Ways to Decompose Bamboo Packaging

There are several effective methods for decomposing bamboo packaging. Each method varies in speed and efficiency depending on the environment and type of bamboo product being composted.

1. Home Composting

For small bamboo packaging items like thin molded trays, paper-like wraps, or uncoated cutlery:

- Suitable For: Untreated, thin bamboo packaging

- Composting Time: 4–6 months

- Best Practices:

- Shred or cut the packaging into smaller pieces

- Add to a compost pile with a balanced ratio of greens (e.g., food scraps) and browns (e.g., dry leaves)

- Maintain moisture and aerate weekly

2. Industrial Composting

Industrial composting facilities maintain higher temperatures (above 55°C), increased microbial activity, and controlled humidity—ideal for thicker or more rigid bamboo items like molded trays, containers, or boxes.

- Suitable For: Larger, denser, or thicker bamboo products

- Composting Time: 2–3 months in optimized conditions

- Best Practices:

- Contact local composting facilities to confirm they accept bamboo-based materials

- Ensure packaging is free from plastic linings or synthetic coatings

3. Landfill Conditions

While bamboo is biodegradable, landfills are not ideal for decomposition. They are anaerobic (oxygen-deprived), which significantly slows the breakdown process and can lead to methane gas production—a potent greenhouse gas.

- Suitable For: Any bamboo packaging (as a last resort)

- Decomposition Time: 1–2 years or more

- Environmental Impact: Much lower than plastic, but not the best method for bamboo waste

4. Alternative Disposal Methods

In regions without composting infrastructure, some low-tech and low-impact methods can still support bamboo decomposition:

- Burial in garden soil: Bamboo packaging can be buried in loose soil in a home garden to slowly decompose and enrich the soil. It takes longer than composting but is fully natural.

- Vermicomposting (worm composting): Some bamboo pulp products may be accepted in worm bins, though care should be taken to avoid items that are too thick or treated.

Market Applications for Bamboo Packaging

Bamboo packaging’s versatility allows it to be used across a wide range of industries. As environmental regulations tighten and consumer preferences shift, its applications continue to expand.

Food and Beverage Industry

Bamboo is increasingly used for takeaway containers, food trays, cups, cutlery, and even beverage packaging. Its heat resistance, moisture tolerance, and antibacterial properties make it ideal for direct food contact.

Some major retailers and restaurants are switching to bamboo as part of their zero-waste initiatives, replacing polystyrene and plastic disposables.

Cosmetics and Personal Care

Luxury skincare and beauty brands are opting for bamboo packaging to elevate product presentation while meeting sustainability goals. Bamboo caps, jars, and sleeves add a natural, elegant touch that aligns with organic or vegan product lines. The tactile feel and aesthetic of bamboo packaging enhance unboxing experiences, increasing perceived value and reducing reliance on non-recyclable plastics.

Electronics and Accessories

Companies are turning to molded bamboo pulp trays and boxes for electronics such as headphones, smartwatches, or mobile accessories. These provide excellent protection and a clean, professional appearance without contributing to e-waste.

Bamboo’s anti-static properties and cushioning ability also make it safer for sensitive components during shipping.

Home Goods and Lifestyle Products

Eco-conscious consumers look for packaging that matches the sustainability of the product inside. From candles and home décor to kitchen utensils and sustainable fashion, bamboo boxes and wraps provide an attractive and earth-friendly solution.

Industrial & Specialty Packaging

Although less common today, bamboo‑based fibre composites may be used in speciality packaging – for example protective trays, pallets, inserts or crates – where companies seek high‑strength, lightweight, renewable materials. Research shows that natural fibre composites (including bamboo) are being adopted for packaging in automotive, aerospace and industrial sectors.

Advantages of Bamboo Packaging for Businesses

From a business perspective, the decision to adopt bamboo packaging should be based on strategic value, not just ethical sentiment. Here are the key business‑centric advantages of embracing bamboo packaging.

1. Regulatory Compliance

As governments worldwide enforce bans on single-use plastics and increase Extended Producer Responsibility (EPR) requirements, bamboo packaging helps businesses comply with legal obligations and avoid penalties. Countries such as Canada, the European Union, and parts of Asia are already phasing out non-recyclable packaging materials.

2. Brand Differentiation and Premium Positioning

Bamboo packaging enables brands to stand out in crowded markets. By combining sustainability credentials with premium look/feel, businesses can communicate authenticity. This may translate into higher perceived value, greater customer loyalty, and willingness to pay more.

3. Reduced Return Rates

Bamboo’s durability ensures products arrive intact, reducing returns caused by damaged goods. This not only saves on logistics costs but also enhances customer satisfaction.

4. Long‑Term Cost and Waste Reduction Benefits

While initial cost may be higher, businesses may derive long‑term savings or value through lower waste disposal costs, improved product durability, fewer returns or complaints, enhanced shelf life, and positive brand‑related lift in pricing or consumer share.

5. Supply Chain Resilience and Future‑Proofing

Bamboo’s fast growth and expanding global cultivation reduce dependency on limited or volatile materials like plastic and timber. Its scalable sourcing supports more stable and diversified supply chains. With rising demand for sustainable materials, early adoption ensures long-term availability and regulatory alignment. This makes bamboo a reliable option for future-focused packaging strategies.

How to Transition to Bamboo Packaging?

Switching from conventional materials to bamboo packaging involves more than replacing one material with another. It’s a strategic move that affects your supply chain, branding, and customer experience. Done right, it positions your company as a leader in sustainability without compromising performance or profitability.

1. Identify Low-Risk Products for Initial Conversion

Start by selecting products that are relatively easy to repackage. Dry foods, shelf-stable items, or single-serve containers are good entry points. These use cases require minimal barrier properties and allow your team to test bamboo packaging without risk to product integrity.

2. Find a Trusted Bamboo Packaging Supplier

Work with manufacturers who specialize in bamboo and understand your industry’s compliance requirements. Ask for documentation around:

- Food contact safety

- Compostability or biodegradability standards

- Minimum order quantities

- Production timelines and scalability

Many reputable bamboo packaging manufacturers are located in China, India, and Southeast Asia. However, several North American and European distributors are emerging to meet growing demand.

3. Redesign for Function, Not Just Form

Bamboo behaves differently from plastic or paper. It may require slight tweaks in structural design to ensure optimal function. Collaborate with packaging engineers who understand both the material’s potential and its constraints.

4. Run Real-World Performance Tests

Before a full launch, test your bamboo packaging across typical storage and transportation conditions. Check for:

- Moisture retention

- Stackability

- Reaction to temperature changes

- End-user experience

Feedback from both logistics teams and customers can help optimize final designs.

5. Train Teams & Communicate with Customers

Internally, your operations and fulfillment teams should be educated on how bamboo packaging handles differently. Externally, educate your customers. Use packaging labels, website messaging, and point-of-sale materials to explain why you’ve chosen bamboo—and how to dispose of it responsibly.

How Long Does Bamboo Packaging Last?

Durability is often a concern when considering eco-friendly packaging, particularly for food items. How long bamboo packaging lasts depends on several factors:

In Storage (Pre-Use):

When stored in a cool, dry environment, bamboo packaging can maintain structural integrity for up to two years. It must be kept away from moisture and direct sunlight, which can degrade the fibers over time.

In Use (Post-Packaging):

Once a product is packaged and exposed to typical environmental conditions—light, humidity, handling—bamboo performs well. It can handle:

After Use (Decomposition):

One of the biggest advantages of bamboo packaging is how quickly it returns to the earth. Under composting conditions, it begins breaking down in as little as 60 days, depending on thickness and coating. Even in a landfill, it will degrade within 4 to 6 months, unlike plastic, which can take centuries.

The Future of Bamboo in Food Packaging

The momentum behind bamboo packaging is no accident. It’s the result of converging trends that point toward a packaging industry ready for reinvention. In food packaging, bamboo is poised to lead the next decade of sustainable design.

Consumer Expectations Are Changing

Today’s consumers expect more than recyclable labels. They want brands that design out waste. Bamboo packaging answers this demand with packaging that is not only functional and attractive but also consistent with their environmental values.

Regulations Are Getting Stricter

Governments around the world are rolling out bans on single-use plastics and mandates for compostable packaging. As these regulations tighten, bamboo packaging—already compliant with most global standards—becomes an obvious choice for brands wanting to future-proof their operations.

Technology Is Improving

As investment in sustainable materials grows, new manufacturing techniques are reducing costs and expanding design possibilities for bamboo packaging. High-precision molding, hybrid material integration, and antimicrobial coatings are already in development.

Brands Are Realizing Marketing Value

Bamboo packaging isn’t just good for the planet—it’s good for positioning. When brands showcase bamboo as part of their packaging story, they communicate innovation, responsibility, and authenticity. It becomes a part of their competitive edge.

Local Supply Chains Are Emerging

With rising demand, more local and regional bamboo processing facilities are opening, especially in Asia, South America, and parts of Africa. This reduces carbon emissions from shipping and creates new employment opportunities in rural communities.

In the next five to ten years, we can expect bamboo to become the gold standard for sustainable food packaging. It’s renewable, safe, and proven. But more importantly, it represents a shift in how we think about materials—not just what we use, but why we use them.

FAQs

- Is bamboo packaging waterproof?

Bamboo is naturally moisture-resistant, but for full waterproofing, an eco-friendly internal lining may be added. - Can bamboo packaging be reused?

Absolutely. Its strength and appearance make it ideal for reuse in households, especially for storage or gift packaging. - Is bamboo packaging safe for food?

Yes. Bamboo is non-toxic and food-safe, especially when untreated or lined with food-grade materials. - Is bamboo packaging more expensive than plastic?

Initially, it may be more costly, but the long-term branding and environmental benefits often outweigh the price difference. - Where can I source bamboo packaging?

You can find certified suppliers in Asia, Europe, and North America. Look for suppliers that offer FSC or other environmental certifications to ensure sustainable sourcing. Millionpack is a Chinese supplier of environmentally friendly food packaging that meets the required safety certifications. - Is bamboo packaging safe for the environment if not composted?

Yes, even if not composted, bamboo packaging breaks down naturally without harming the environment.

Conclusion

In a world where single‑use plastics, global waste streams and carbon emissions are pressing issues, packaging must evolve. Bamboo packaging offers a compelling solution: a rapidly renewable raw material, with strong environmental credentials, industrial versatility, and growing appeal among consumers and brands who prioritise sustainability and design.

But to realise its full promise, brands and manufacturers must act with expertise and integrity: sourcing responsibly, processing thoughtfully, ensuring end‑of‑life recovery, and communicating transparently. When these conditions are met, bamboo packaging becomes not only an environmentally friendly alternative, but also a strategic asset that can perfectly combine brand mission, consumer values, and supply chain innovation.