In today’s fast-paced world, where food safety and sustainability are at the forefront of consumer consciousness, food grade plastic has become an essential part of packaging and storage systems. From takeout containers to commercial food packaging, its usage is widespread — but how much do we really know about it?

This comprehensive guide explores what qualifies as food grade plastic, why it matters, and how it differs from ordinary plastics. You’ll also discover the most common types used in the food industry, how to identify them, and how they align with safety regulations and environmental goals. Whether you’re a consumer, manufacturer, or food business owner, understanding food grade plastic is key to ensuring health, safety, and compliance.

What Is Food Grade Plastic?

Food grade plastic refers to plastic materials that are considered safe for use with food and beverages. These materials must meet specific regulatory standards to ensure they do not leach harmful substances into consumables. In most countries, especially the United States and the EU, such plastics must comply with rigorous food safety standards such as those set by the U.S. Food and Drug Administration (FDA) or the European Food Safety Authority (EFSA).While some are inert and safe, others can break down over time or under stress, releasing dangerous chemicals such as BPA (Bisphenol A) or phthalates.

Key characteristics of food grade plastic include:

- Non-toxic and non-reactive with food or beverages.

- Resistant to heat and cold.

- Free of dangerous additives or contaminants.

- Stable over time, without degrading into harmful components.

By choosing food grade plastic, consumers and businesses alike can ensure safer food handling and storage, while maintaining regulatory compliance and consumer trust.

Types of Food Grade Plastic Used in Packaging and Containers

Different types of food grade plastic serve various purposes depending on their structural properties, cost, and compatibility with different food types. Below are the most widely used types in the food industry, along with their advantages and common applications.

1. High-Density Polyethylene (HDPE)

HDPE is one of the most popular materials in the realm of food packaging. It is sturdy, moisture-resistant, and doesn’t leach into food, making it ideal for milk jugs, juice bottles, and food storage containers.

- Properties: Lightweight, durable, and highly resistant to impact.

- Applications: Cereal box liners, milk containers, cutting boards.

2. Low-Density Polyethylene (LDPE)

Softer and more flexible than HDPE, LDPE is used primarily in plastic wraps and squeezable bottles. It is safe for direct food contact and resistant to acids and bases.

- Properties: Flexible, clear, and chemically stable.

- Applications: Bread bags, frozen food packaging, condiment bottles.

3. Polypropylene (PP)

Known for its high melting point, PP is often used in containers that must endure hot fillings or microwave reheating. It’s also resistant to chemicals, oils, and solvents.

- Properties: Strong, resistant to heat, chemically inert.

- Applications: Yogurt containers, microwavable trays, reusable food containers.

4. Polyethylene Terephthalate (PET or PETE)

Widely used for beverage containers and prepackaged foods, PET is clear, strong, and lightweight. It has excellent gas and moisture barrier properties.

- Properties: Clear, rigid, recyclable.

- Applications: Soda bottles, salad dressing containers, food jars.

5. Polycarbonate (PC)

Once popular for its strength and transparency, PC is now less common due to concerns about BPA. However, BPA-free versions are still in use for items like baby bottles and large water jugs.

- Properties: Extremely durable and shatter-resistant.

- Applications: Baby bottles (BPA-free), large water bottles.

Each of these types of food grade plastic has been tested and approved for safe food contact. However, consumers must still pay attention to labels and symbols to ensure safe usage.

Is Food Grade Plastic Safe for Everyday Use?

The safety of food grade plastic is one of the most common concerns among consumers. With growing awareness of toxins and long-term health risks, questions often arise about whether these plastics are truly safe — especially when exposed to heat, microwaves, or acidic foods.

1. FDA and Global Regulations

Plastics that qualify as “food grade” must pass stringent tests and receive certifications from authorities such as the FDA in the U.S. or EFSA in Europe. These tests evaluate the material’s potential to release harmful substances under normal usage conditions.

2. BPA and Phthalates

One of the biggest controversies revolves around BPA, a chemical used in some polycarbonate plastics. BPA has been linked to hormonal disruptions and is no longer permitted in baby bottles or children’s food containers in many countries. Fortunately, most modern food grade plastic products are now BPA-free and labeled accordingly.

3. Microwave and Freezer Safety

Not all food-safe plastics are designed for extreme temperatures. Only certain types, like PP and HDPE, are suitable for microwave or freezer use. Using the wrong plastic in high-heat environments can lead to chemical leaching.

4. Lifespan and Reuse

Even when made of food grade plastic, containers have a finite lifespan. Scratches, stains, or warping can indicate that the material’s structure is compromised, increasing the risk of contamination.

The key takeaway: food grade plastic is generally safe when used as intended. Always check labels, avoid heating unknown plastics, and replace containers that show signs of wear.

How to Identify Food Grade Plastic at Home

Recognizing food grade plastic isn’t just for manufacturers — consumers can also verify it by checking packaging symbols, material codes, and labels.

1. Look for Recycling Codes

Most plastic products include a recycling triangle with a number from 1 to 7. Not all of these are suitable for food contact:

SAFE:

- #1 PET – Safe for one-time use; not for reuse.

- #2 HDPE – Highly safe and durable.

- #4 LDPE – Safe for wrapping and soft containers.

- #5 PP – Microwave-safe and commonly used.

AVOID:

- #3 (PVC):can release harmful chemicals such as chlorine and phthalates, which may disrupt hormones and damage the liver or kidneys when food comes into contact with it.

- #6 (PS):may leach styrene, a possible carcinogen linked to nervous system damage and other long-term health effects, especially when heated or used with acidic foods.

- #7 (Other unless labeled BPA-free).:especially those made with polycarbonate, can contain BPA, a chemical associated with hormonal imbalance, reproductive issues, and potential developmental problems in children.

2. Labels and Certifications

Look for terms like:

- “BPA-Free”

- “FDA Approved”

- “Microwave Safe” or “Freezer Safe”

3. Smell and Appearance

Quality food grade plastic should not have a strong chemical odor. It should feel smooth, not greasy, and shouldn’t change appearance after washing.

Food Grade Plastic vs. Regular Plastic: Key Differences

While all food grade plastics are plastics, not all plastics are food grade. Here’s how they differ:

| Criteria | Food Grade Plastic | Regular Plastic |

|---|---|---|

| Safety | Certified non-toxic, stable | May release chemicals or leach toxins |

| Regulations | FDA/EFSA compliance | No specific requirements |

| Application | Used in food packaging & storage | Industrial, construction, etc. |

| Temperature Tolerance | Tested for heating/cooling | Often not heat-resistant |

| Cost | Slightly higher due to testing | Lower, but riskier for food contact |

When it comes to health and safety, the extra cost of using food grade plastic is a worthwhile investment.

Sustainability and Recycling of Food Grade Plastics

The conversation around plastics has shifted significantly toward sustainability. While food grade plastic is necessary for hygiene and shelf life, it raises concerns about waste and environmental impact

1.Recyclability

Many types of food grade plastic (especially #1, #2, and #5) are recyclable. However, local recycling capabilities vary, and food residue often complicates the process.

2.Reusable Alternatives

Some companies now offer food grade plastic containers that are reusable and dishwasher-safe, reducing the need for single-use items.

3.Bioplastics and Innovation

The future of food grade plastic includes compostable materials and plant-based alternatives like PLA. These are promising, but they also face hurdles like infrastructure limitations and higher production costs.Being eco-conscious while using food grade plastic means choosing reusable over disposable, recycling responsibly, and supporting innovations that reduce plastic dependence.

Application Cases of Food-Grade Plastics in Food Enterprises

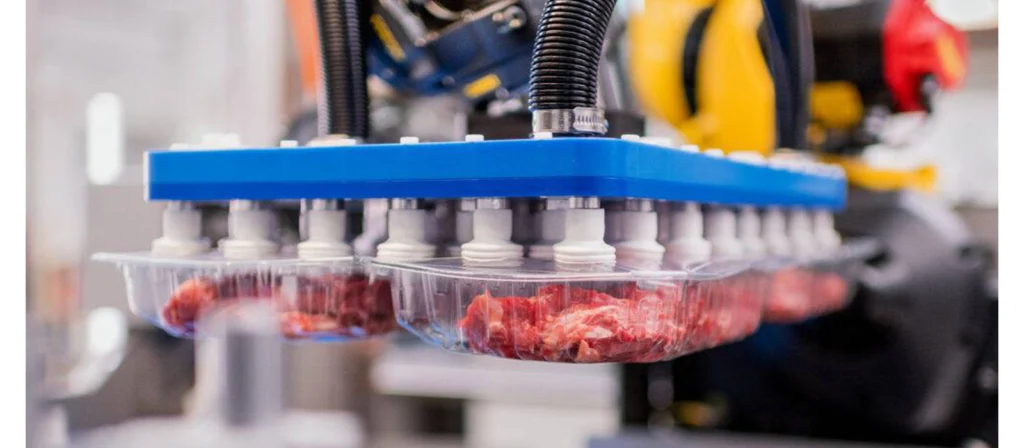

1. Common Applications of Food-Grade Plastics in Enterprises

In commercial food production and packaging, food grade plastic is not only crucial for preserving product quality and safety but also significantly affects operational efficiency and cost control. For enterprises handling large volumes of food, the right choice of plastic materials can lower contamination risks, improve shelf life, and reduce packaging expenses.

From a cost perspective, food grade plastic offers an economical alternative to glass or metal, particularly in high-throughput operations. Its lightweight nature reduces transportation costs, while durability ensures fewer breakages during handling and shipping. For instance, HDPE and PP are far less expensive to manufacture and transport than rigid glass or stainless steel, and they support faster automated packaging processes — a major cost-saving factor for large food manufacturers.

Here are some of the most common applications across various sectors:

- Dairy Industry: HDPE is used for milk jugs, cheese containers, and yogurt tubs.

- Beverage Industry: PET bottles are the standard for juices, water, and soft drinks.

- Frozen Foods: LDPE and PP are used for packaging ready-to-eat meals and ice cream.

- Food Processing Plants: PP trays and HDPE pallets streamline large-scale handling and transportation.

- Food Service Industry : PLA,PP and PS (Polystyrene) are frequently used for disposable plastic knives, forks, spoons, and cups, especially in quick-service restaurants, cafeterias, and catering

2. Examples of food-grade plastics applications in the Food Service Industry

In the food service industry, food grade plastics are essential for both front-of-house and back-of-house operations. Polypropylene (PP) and HDPE are commonly used for reusable food storage containers in commercial kitchens, due to their resistance to heat, staining, and chemical degradation during repeated cleaning cycles.

Takeout and delivery services rely heavily on PET for clear food containers and lids, providing strong barriers against moisture and oxygen while showcasing food visually. Meanwhile, LDPE is widely used in disposable gloves, cling films, and squeeze bottles — offering flexibility and food-safe performance during food prep and service.

These applications highlight how food grade plastic supports safety, hygiene, and efficiency throughout the food service workflow — from preparation and cooking to packaging and delivery.

Conclusion

Understanding food grade plastic is no longer optional—it’s essential. From everyday home use to large-scale food manufacturing, these materials form the backbone of modern food safety and hygiene. Whether you’re a consumer looking to make safer choices or a business aiming to meet compliance standards, knowing the types, properties, and applications of food grade plastics can significantly impact your decisions.

Safe when used correctly, recyclable in many cases, and increasingly innovative in composition, food grade plastic represents the evolving relationship between convenience, safety, and sustainability. But with this convenience comes responsibility: check labels, understand material codes, and opt for high-quality, certified products whenever possible.

FAQs About Food Grade Plastic

1. What makes a plastic “food grade”?

A plastic is considered food grade when it meets strict safety standards set by regulatory agencies like the FDA or EFSA. It must not contain harmful chemicals, must not react with food, and must remain stable under normal storage or usage conditions.

2. How can I tell if a plastic container is food grade?

Check for recycling codes like #1 (PET), #2 (HDPE), #4 (LDPE), or #5 (PP), and look for labels such as “BPA-Free,” “FDA Approved,” or “Microwave Safe.” Smell and appearance can also be indicators—food grade plastic should not have a strong chemical odor.

3. Is food grade plastic safe in the microwave?

Some types of food grade plastic, such as polypropylene (PP), are microwave-safe. However, not all food-safe plastics can withstand high heat. Always check the container label to confirm suitability for microwave use.

4. Can I reuse food grade plastic containers?

Yes, many food grade plastic containers are designed for reuse, especially those made from HDPE or PP. However, repeated washing and heating can degrade the material, so it’s important to inspect for cracks, warping, or discoloration.

5. What’s the difference between food grade and food safe plastic?

“Food grade” means the plastic is safe for food contact according to regulations. “Food safe” typically means the plastic has been tested in its final form (including dyes and treatments) and proven not to transfer harmful substances to food.

6. Are there eco-friendly options for food grade plastic?

Yes, bioplastics and compostable materials like PLA are emerging alternatives, and many traditional food grade plastics like PET and HDPE are recyclable. Still, these options depend on local recycling systems and the absence of food contamination.