Flexographic printing is a modern printing method that uses flexible relief plates to transfer ink onto a wide range of materials. It works by coating raised image areas with fast drying inks and pressing them onto substrates such as paper, film, foil, and corrugated cardboard. Flexographic printing is widely used in packaging, labels, and other high volume production because it supports continuous and efficient printing.

- Flexographic printing is a fast, versatile printing method ideal for packaging and labels.

- Flexible plates are used to transfer ink onto a wide range of materials, including plastic, paper, and foil.

- High-speed production makes flexo great for large print runs with consistent quality.

- Eco-friendly inks and materials can be used in flexo, making it more sustainable than some alternatives.

- Ideal for continuous patterns, like wrapping paper or wallpaper, due to its roll-to-roll printing format.

As packaging and consumer goods continue to expand globally, flexographic printing has become one of the most important printing technologies for businesses seeking high quality results at large scale. Its versatility, speed, and ability to print on almost any surface make it a preferred choice for industries that need consistent and cost effective production.

In this guide, we will explore how flexographic printing works, its key components, advantages, applications, and how it compares to digital printing and other traditional methods. By the end, you will have a clear understanding of why flexographic printing remains a leading solution in today’s printing and packaging world.

Types of Flexographic Printing

Flexographic printing technology is not monolithic. It has evolved into distinct forms that serve specific market needs. The two main categories are traditional and enhanced flexographic printing.

Traditional Flexographic Printing

Traditional flexographic printing is what most people refer to when they mention “flexo.” It involves manually mounted photopolymer plates, mechanical ink controls, and standard drying systems. While modern in many ways, traditional flexo still relies heavily on the operator’s expertise to maintain registration, ink consistency, and plate longevity.

This method is cost-effective for long print runs with minimal changes. It’s best suited for applications like:

- Corrugated boxes

- Paper bags

- Simple labels

- Wrapping paper

Enhanced Flexographic Printing

Enhanced or “modern” flexographic printing incorporates digital and automated technologies to improve precision, quality, and efficiency. These presses feature servo-driven components, fully automated registration systems, and software-driven workflows that minimize human error.

By choosing the appropriate flexo variant, businesses can align production capabilities with quality expectations and market demands. Whether it’s a simple monochrome shipping label or a vibrant, multi-layered pouch, there’s a flexo solution fit for the job.

Flexographic Printing Process

Flexographic printing operates on a roll-to-roll system, where substrate materials are fed through a press and printed using flexible plates mounted on rotating cylinders. These plates carry raised images that pick up ink and transfer it onto the material, layer by layer, to produce the final printed image.

The process is optimized for high-speed and high-volume production, making it ideal for industries that rely on efficiency, such as food packaging, labeling, and industrial wrapping.

Working Principle

Rollers are at the core of the flexographic printing mechanism. Each roller plays a distinct role in transferring ink, forming the image, and applying it precisely to the substrate. The four main types of rollers used: a fountain roller, an anilox roller, the plate cylinder, and the impression cylinder.

To understand the inner workings of flexographic printing, imagine a continuous, high-speed version of a stamp. But instead of manually pressing ink onto paper, the process uses rotating cylinders, each playing a specific role, to achieve consistent and scalable results.

At the heart of this method is the flexible printing plate, made from rubber or photopolymer material. These plates are mounted onto the plate cylinder, where each one carries an image or pattern to be printed. The image areas on the plate are raised, while the non-image areas remain recessed. This relief printing technique ensures that only the raised portions come in contact with the ink.

Here’s a simplified breakdown of the flexographic working mechanism:

- Ink Application: An ink reservoir feeds ink to the anilox roller, which is engraved with thousands of tiny cells. These cells control the amount of ink transferred to the plate.

- Ink Transfer: The anilox roller lightly touches the flexographic plate, evenly distributing a precise layer of ink onto the raised image areas.

- Impression: The plate then makes contact with the substrate (the material being printed on), transferring the ink in the exact shape of the image.

- Drying: After each color is applied, the substrate passes through a drying station. This ensures rapid drying, especially crucial for fast-moving production lines.

What makes flexo particularly unique is its ability to print on non-absorbent and uneven surfaces, something other printing methods struggle with. Whether it’s a glossy pouch or corrugated cardboard, flexo’s adaptable nature allows it to deliver consistent results across a range of textures and thicknesses.

Materials and Inks Used

Flexographic printing is admired for its material flexibility. Unlike many other printing methods that are limited to flat or absorbent surfaces, flexo accommodates a wide array of substrates.

Common Substrates:

- Paper: Kraft, coated, uncoated

- Corrugated board: Ideal for shipping containers and retail packaging

- Plastic films: Polyethylene (PE), Polypropylene (PP), Polyvinyl chloride (PVC)

- Foils: Aluminum and other metallic materials

- Laminates: Used in food packaging and flexible pouches

- Non-woven textiles: Used for hygiene products and industrial applications

Types of Inks:

The type of ink used is critical to ensuring adhesion, color vibrancy, and environmental compliance. Flexographic printing commonly utilizes three types of inks:

1. Water-Based Inks:

Primarily used on porous surfaces like paper and corrugated board. They offer fast drying, are environmentally friendly, and pose fewer health hazards during handling.

2. Solvent-Based Inks:

Best suited for non-absorbent substrates such as plastic films. These inks provide excellent adhesion and resistance to moisture and abrasion, although they require controlled ventilation and proper disposal due to VOC (volatile organic compounds) emissions.

3. UV-Curable Inks:

Rapid curing through ultraviolet light makes them ideal for high-speed printing and high-detail jobs. They work well on a variety of surfaces and offer excellent print quality, although they require specialized curing equipment.

The ability to select from a wide variety of inks based on substrate and application is what makes flexographic printing exceptionally versatile across industries.

Flexographic Printing Process Steps

Understanding the full workflow from design to final output reveals the efficiency and technical sophistication of flexography. Here’s a step-by-step breakdown:

- Prepress and Design Preparation

Digital artwork is created and adjusted for print, including color separation, trapping, and bleed setup. - Plate Making

Photopolymer or rubber plates are produced using laser engraving or exposure methods, with raised areas for printing. - Plate Mounting

Plates are mounted onto cylinders with precise alignment to ensure accurate registration during printing. - Press Setup and Inking

Anilox rollers and ink stations are configured. Ink flow, pressure, and drying parameters are calibrated for the job. - Printing Process

Substrate moves through color stations where ink is transferred from plate to material in a continuous motion. - Drying and Curing

Each ink layer is dried using heat, hot air, or UV curing before the next color is applied to prevent smudging. - Post-Processing

Printed materials may be laminated, cut, or varnished depending on the final product requirements. - Quality Control and Finishing

Visual inspections and camera systems check for defects. Approved rolls or sheets are packed and prepared for delivery.

Advantages and Disadvantages of Flexographic Printing

Flexographic printing has grown into one of the most prominent technologies in packaging and labeling. Understanding both its strengths and limitations is essential for businesses deciding whether it’s the right solution for their needs.

Advantages of Flexographic Printing

- High-speed operation: Capable of producing thousands of impressions per hour.

- Substrate versatility: Works with both absorbent and non-absorbent materials.

- Cost-effective for long runs: Once set up, the unit cost per print is low.

- Fast drying: Utilizes low-viscosity inks that dry quickly, minimizing smudging and downtime.

- Eco-friendly options: Water-based and UV-curable inks are widely available.

Disadvantages of Flexographic Printing

- High initial setup costs: Plate production and press setup can be expensive.

- Lower detail resolution: Not ideal for ultra-fine images or detailed photo reproduction.

- Limited color accuracy: Spot color matching can be complex compared to digital printing.

Suitable Packaging Materials for Flexographic Printing

Flexographic printing is a powerhouse in the packaging world largely because of its ability to work with such a wide range of materials. From flexible films to rigid cartons, flexo’s adaptability allows it to meet diverse packaging needs across industries.

Here are some of the most commonly used materials in flexographic printing:

- Paper and Cardboard

Common for cartons, shopping bags, and corrugated boxes. Flexo handles these porous surfaces well, especially when using water-based inks. - Plastic Films (PE, PET, BOPP)

Widely used for snack packaging, pouches, and shrink sleeves. Flexo printing excels here when combined with solvent or UV-curable inks for better adhesion and quick drying. - Aluminum Foil

Often used in food and pharmaceutical packaging. Requires precise ink control and fast curing to prevent wrinkling or heat damage. - Biodegradable and Compostable Films

As sustainable packaging gains popularity, flexo has proven capable of printing on eco-friendly materials like PLA and cellulose-based films, provided ink formulations are adjusted accordingly. - Non-woven Fabrics

Used in hygiene products and medical packaging. Flexo presses with gentle pressure control can print effectively on these delicate surfaces.

Choosing the right material depends on factors like product type, required shelf life, environmental considerations, and regulatory compliance. Flexographic printing offers the flexibility to adapt to these demands without compromising on print quality or durability.

Advantages of Flexographic Printing in Food Packaging

Food packaging demands precision, hygiene, and speed—criteria that flexographic printing meets exceptionally well. As a result, flexo is widely used in the food industry, from ready-to-eat meals to fresh produce and snack products.

1. Food-Safe Inks and Materials

Flexographic printing supports the use of certified food-grade inks and coatings, which comply with health and safety standards globally.

2. High-Speed Output

Fast production capabilities help food companies meet tight delivery schedules and keep up with high consumer demand, especially for perishable goods.

3. Wide Material Compatibility

Whether it’s plastic film, foil, paper, or compostable packaging, flexo can print effectively across all major substrates used in the food industry.

4. Barrier Protection Compatibility

Flexo is compatible with functional packaging materials that offer moisture, oxygen, and UV protection, critical for extending food shelf life.

5. Crisp Branding and Regulatory Compliance

Packaging must display brand colors, ingredients, barcodes, nutritional facts, and expiration dates. Flexographic printing offers sharp, clear reproduction of both graphics and small text, ensuring brands comply with regulations while maintaining visual appeal.

6. Cost Efficiency in Competitive Markets

Margins in food production are narrow, making cost-efficient packaging essential. Flexographic printing lowers per-unit costs over large runs and supports inline processes like varnishing, perforating, and die-cutting, reducing reliance on multiple machines or vendors.

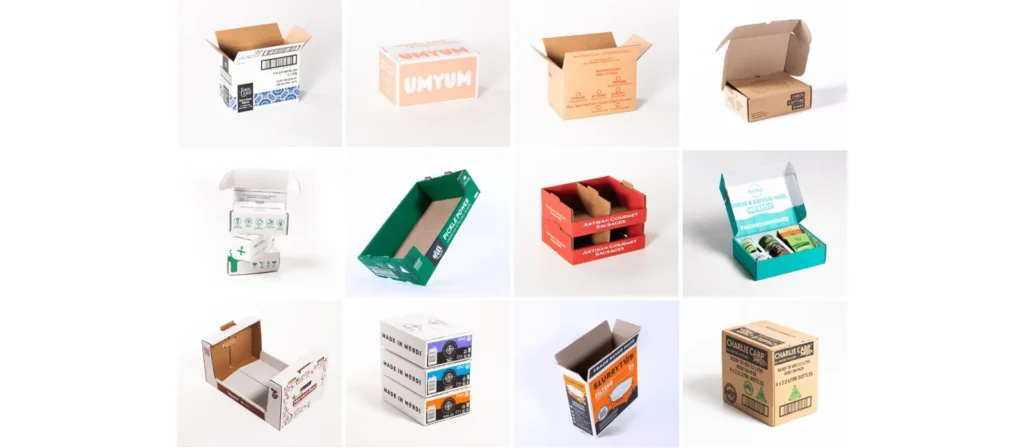

Common Applications of Flexographic Printing

Flexographic printing is widely used across a diverse range of industries due to its versatility, speed, and ability to print on various materials. Below are some of the most common applications:

- Food packaging (snack bags, frozen food pouches, wrappers)

- Beverage labels (bottled water, soft drinks, juice containers)

- Pharmaceutical and medical packaging (blister packs, sachets, labels)

- Personal care and cosmetics packaging (tubes, cartons, foils)

- Retail packaging (shopping bags, branded boxes, shelf-ready packs)

- E-commerce packaging (corrugated boxes, mailing bags, tape)

- Household product packaging (cleaning supplies, detergents, wipes)

- Industrial labels (warning labels, part identification, chemical packaging)

- Agricultural packaging (fertilizer bags, seed packets, plant tags)

Flexographic Printing vs. Offset Printing

Flexographic and offset printing are two of the most widely used printing methods in commercial and packaging industries. While both offer high-quality results, they differ significantly in terms of technology, cost structure, substrates, and use cases.

| Feature | Flexographic Printing | Offset Printing |

|---|---|---|

| Printing Plate | Flexible photopolymer plates | Rigid metal plates |

| Best Materials | Plastic, film, foil, cardboard | Paper and flat surfaces |

| Print Quality | Very good, especially for packaging | Excellent for high-resolution images |

| Setup Cost | Higher initial setup, faster production | Lower setup cost for small to medium runs |

| Speed | Extremely fast, ideal for long runs | Slower, better for detailed work |

| Use Cases | Packaging, labels, flexible materials | Books, brochures, paper-based prints |

Advances in Flexographic Printing Technology

Recent developments in flexographic printing have significantly improved print quality, speed, and consistency. High-resolution digital plate imaging, flat-top dot technology, and sleeve systems now allow for sharper graphics, faster changeovers, and tighter registration control. Servo-driven presses and closed-loop color systems ensure precision and reduce waste, making the entire process more efficient.

Environmental improvements have also shaped the industry. The rise of water-based and UV-curable inks, along with energy-efficient LED curing systems, has made flexo more sustainable. Combined with workflow automation and hybrid flexo-digital presses, flexographic printing is now more agile, eco-friendly, and suitable for complex packaging needs.

FAQs

- What is the typical run length for flexographic printing?

Flexographic printing is well suited for medium to high volumes. While very short runs (e.g., a few hundred units) may be better served by digital printing, many packaging operations begin to see economies of scale with flexo for runs in the thousands or more. - Can flexographic printing handle high-resolution graphics?

Yes, modern flexo technology has improved a lot! With digital plate-making and UV inks, flexo now produces sharp, detailed images suitable for branding and fine graphics. - Is flexographic printing eco-friendly?

It can be! When used with water-based or UV-curable inks and sustainable substrates, flexographic printing offers a lower environmental impact than many other print methods. - How long do flexographic printing plates last?

With proper care, flexo plates can last for hundreds of thousands of impressions. Some high-quality plates are reusable and durable across multiple production runs. - Can flexographic printing handle detailed designs?

It can handle moderate detail well, but extremely fine detail is better suited to digital or gravure printing.

Conclusion

Flexographic printing is a powerful, adaptable and increasingly sophisticated printing method — ideally suited for the demands of modern labeling, packaging and industrial print markets. With its ability to print on a broad array of substrates, high production speeds, integration of finishing processes and ongoing improvements in print quality and sustainability, flexography remains a compelling choice for many producers.

If your business deals with flexible films, plastic pouches, metallic laminates, corrugated cartons or high‑volume labels, flexo is likely a strong contender. By staying abreast of evolving substrates, finishes and digital workflows, flexographic printing will continue to evolve and remain relevant for years to come.