In the world of food packaging, first impressions can make or break a product. When shoppers browse shelves filled with cookie boxes, pasta cartons, and frozen meals, what often catches their eye first isn’t a flashy logo. It’s the ability to actually see what’s inside. That’s where window patching comes in. This packaging technique, which adds a transparent film over a die-cut opening, gives consumers a clear view of the product while keeping it sealed, fresh, and safe.

But window patching is more than just a see-through gimmick. For food brands, it’s a strategic tool that builds trust, showcases quality, and boosts shelf appeal. Whether you’re marketing artisan bread or sugar-dusted donuts, showing off the goods adds real value. In this guide, we’ll break down everything you need to know about window patching in food packaging, from materials and machine processes to smart design tips and real-world examples. Let’s open the box and get started.

What is Window Patching in Food Packaging?

Window patching is a packaging technique that involves applying a clear plastic film over a die-cut opening on a food box or carton. This creates a transparent window that allows customers to see the product inside while maintaining safety, hygiene, and freshness. You’ll often spot this on bakery boxes, pasta cartons, snack packs, and even some frozen food containers.

In food packaging, visibility plays a huge role in building consumer confidence. When shoppers can actually see the golden crust of a loaf of bread or the texture of pasta inside the box, they’re far more likely to buy. The window not only showcases the product, but also adds a layer of authenticity and quality perception.

Window patching also helps food brands combine visual appeal with practicality. It supports structural strength by keeping most of the box made from paperboard, while using just enough transparent film to display the product clearly. For categories where appearance matters, like sweets, dry goods, or artisanal snacks, it’s a strategic design choice that makes a real difference.

Key Design Considerations in Food Packaging

Designing effective window patching for food packaging involves more than simply cutting a hole and adding a clear film. The process must account for how the packaging will perform in real-world conditions—from the production line to store shelves and even customer homes. Several factors come into play, including the size and shape of the window, the type of film used, and how the package will respond to environmental conditions such as cold storage or humidity.

Each of these design decisions can impact not just appearance but also functionality, strength, and customer perception. Let’s take a closer look at the key considerations that guide successful window patching in food packaging.

Window Size and Shape

One of the first things to consider when implementing window patching in food packaging is the size and shape of the window. A larger window gives consumers a better view of the product, which can enhance trust and visual appeal. However, going too big can weaken the box structure, especially if the packaging holds heavier or delicate food items.

Designers must find the sweet spot between visibility and durability. A window that is too small might not showcase the product well enough, while one that’s too large might reduce the strength of the packaging or complicate stacking. In bakery packaging, for example, a rectangular window across the top may work well for flat items like brownies, while a smaller circular window might suit cupcakes or tarts.

The shape also plays a role in how the product is perceived. Rounded corners are easier to patch and less prone to tearing during production. Custom shapes like hearts or stars can be eye-catching but may slow down manufacturing or increase material waste. Ultimately, the design should highlight the most appealing part of the product while preserving the box’s integrity.

Rigidity vs. Flexibility of Window Films

Choosing between rigid and flexible films is a critical decision in food packaging design. The type of film used in window patching directly affects how the package performs during production, transport, and display. Each type has distinct characteristics that make it more or less suitable for different kinds of food products.

Rigid films, such as PET, offer excellent clarity and a high-end appearance. They hold their shape well, making them ideal for packaging that needs to maintain a flat surface or structural integrity. This is particularly useful for premium products like chocolates, pastries, or frozen meals where a polished, upscale look is part of the brand experience.

On the other hand, flexible films like polypropylene are lightweight, cost-effective, and more forgiving when the packaging is squeezed, bent, or stacked. These films work well for snack foods, cereals, and other items where durability and flexibility are more important than a glass-like finish. They’re also better suited for machines that require tighter rolls or curved surfaces.

The choice between rigid and flexible films depends not only on the product type but also on the packaging design, transportation method, and retail environment. The key is to match the film’s properties with the packaging’s purpose and the customer’s expectations.

Temperature, Humidity, and Freezing Resistance

When it comes to food packaging, environmental conditions like temperature and humidity can make or break the performance of a window patch. Not all films respond the same way to cold storage, warm display cases, or humid environments, so selecting materials and adhesives that can handle these variables is essential.

For refrigerated or frozen products, films must resist fogging and cracking. Common problems include condensation forming on the inside of the window or the film becoming brittle when exposed to freezing temperatures. Using anti-fog coatings or selecting films with better thermal tolerance can help maintain clarity and durability in cold conditions.

In humid environments, such as tropical regions or high-moisture retail spaces, adhesives must also be chosen carefully. A poorly matched adhesive could cause the window film to lift, wrinkle, or even fall off over time. Proper sealing methods and moisture-resistant materials ensure that window patching holds up throughout the product’s shelf life.

Whether packaging is displayed in a chilled cabinet or shipped across hot climates, understanding how environmental factors interact with the window patching system is key to delivering a reliable and visually appealing product.

Functional and Marketing Benefits

Window patching offers more than just a peek inside the box. It delivers practical value from both functional and branding perspectives. For food products, especially those sold in retail environments, packaging needs to work hard. It must protect the product, inform the buyer, attract attention, and support the brand. Window patching supports all of these goals by blending visibility with visual impact.

Here are four key benefits that explain why this technique is widely used in food packaging today.

Improves Product Visibility

Allowing customers to see the actual food inside the packaging reduces hesitation and builds immediate trust. Whether it’s a frosted cupcake or a crunchy granola bar, visual access helps shoppers quickly assess freshness and quality. Window patching makes that decision feel more confident and effortless.

Builds Consumer Confidence

When buyers can view the real product instead of relying on printed images, they feel more secure about their purchase. This sense of transparency improves satisfaction and lowers the chance of returns or disappointment. Window patching makes expectations clearer and results more reliable.

Enhances Shelf Presence

In a crowded store aisle, packaging that shows the product inside naturally stands out. Window patching adds a visual break that grabs attention and helps differentiate your product from competitors. This visibility can increase the chance of a product being picked up and purchased.

Adds a Premium Look and Feel

A well-designed window adds more than function. It communicates care, craftsmanship, and attention to detail. Many premium food brands use custom-shaped windows, printed frames, or embossing around the window to give the packaging a high-end, giftable look that elevates the product’s perceived value.

Window Patching Machinery and Processes

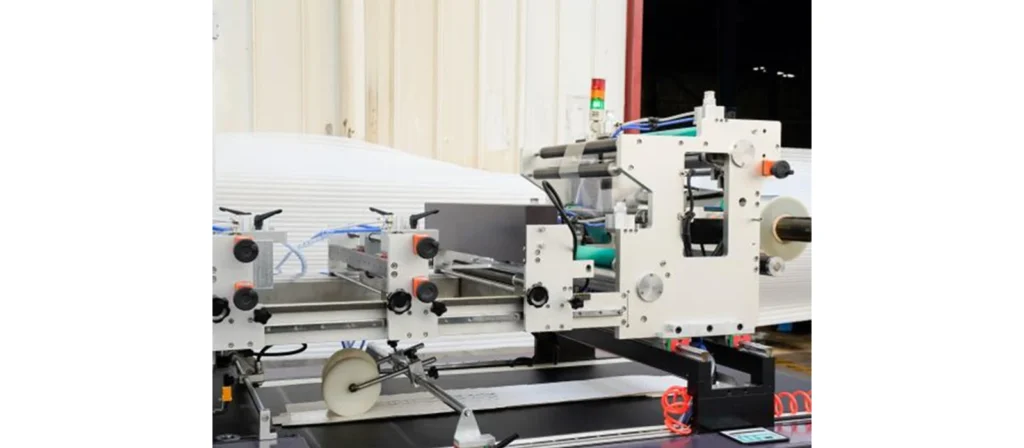

The window patching process in food packaging is carried out using automated machinery designed for speed, hygiene, and accuracy. It begins with flat cartons that have already been die-cut with a window opening. These cartons are fed into the machine, where a thin layer of food-safe adhesive is applied around the edges of the cut-out area. A roll of transparent film is then unwound and cut into pieces matching the required window size. Each film segment is placed over the adhesive area and pressed into position. Once the film is securely attached, the carton moves on to the next stages of the packaging line, such as folding, gluing, and final assembly. This process ensures that each package has a clean, sealed window that enhances product visibility while maintaining food safety standards.

Window patching systems are often integrated into broader packaging lines, allowing for seamless high-speed production. These machines are optimized for minimal waste, consistent precision, and compatibility with various carton sizes and materials. For food manufacturers, the process supports both scalability and compliance with hygiene regulations, making it a practical choice for mass-market as well as premium product lines. In short, window patching is not just a design element, but a well-engineered system that supports product integrity, customer appeal, and production efficiency at scale.

Best Use Cases in the Food Industry

Window patching is widely used in the food industry because it allows consumers to see the product before purchasing while keeping it protected and sealed. It’s especially effective in categories where product appearance influences buying decisions. From fresh pastries to frozen meals, here are the most common types of food packaging that benefit from this technique.

Bakery and Pastry Boxes

Bakeries often use window patching to showcase items like cakes, cookies, and bread. A clear window lets customers see the frosting, texture, and freshness without opening the box. This visibility adds trust and appeal, especially for handcrafted or premium products.

Pasta, Cereals, and Dry Goods

Dry foods with unique shapes or colors, such as pasta, grains, or cereals, benefit from transparent packaging. A window on the front of the box highlights the product’s quality and visual variety, helping it stand out on crowded retail shelves.

Frozen and Refrigerated Food

For frozen meals, ready-to-eat dishes, or refrigerated snacks, window patching offers a way to display ingredients or portion size while keeping the contents sealed. The right film material ensures durability even in cold or humid storage conditions.

Conclusion

Window patching plays a powerful role in modern food packaging by blending visibility with protection. It gives consumers the ability to see what they’re buying while keeping products sealed and hygienic. From bakery boxes to frozen meals, this simple design element builds trust, improves shelf presence, and helps food brands stand out in highly competitive retail environments.

As packaging continues to evolve with consumer expectations, the strategic use of window patching can make a clear difference. Whether you’re designing for artisan bread or pre-packed pasta, a well-placed transparent window tells your product’s story before it’s even opened. For food brands looking to connect visually and deliver confidently, window patching is a tool worth using.

At Million Pack, we specialize in high-quality, food-safe window patching solutions tailored to your brand and product needs. From material selection to structural design and production, our team helps you create packaging that performs on the shelf and delights in the hands. Let us help you turn visibility into value.

FAQs

Is window patching safe for direct contact with food?

In most cases, no. The clear film used in window patching is not intended to touch the food directly. It is applied to the outside of cartons or boxes that contain wrapped or separated food items.

Can window patching be used for frozen or refrigerated food products?

Yes. As long as the correct film and adhesive are used, window patching can perform well in cold environments without fogging, peeling, or cracking.

Does the window patch affect recyclability of the packaging?

It can. When the plastic film is bonded to a paperboard surface, the materials may need to be separated for proper recycling. Some packaging is designed to make this easier, but not all recycling systems can handle mixed materials.

How does window patching impact packaging costs?

Window patching adds an extra step in production, which can slightly increase costs. However, the added product visibility often improves sales and offsets the investment through stronger shelf appeal.

What types of food are not suitable for window patching?

Foods that are oily, sticky, or directly contact the inside of the box may not be ideal for window patching unless there is an inner wrap. Items requiring airtight packaging are also better served by fully sealed plastic or vacuum packs.