Greaseproof paper is a type of oil-resistant paper used widely in foodservice settings, from cafés and bakeries to high-volume takeaway kitchens. It is designed to prevent oil, fat, and moisture from seeping through, making it ideal for wrapping burgers, lining pastry boxes, or baking without the mess. For commercial kitchens, it is not just a convenience. It is a clean, efficient, and brand-enhancing solution.

Whether you’re packing a buttery croissant or plating up crispy fried snacks for delivery, greaseproof paper helps food stay presentable and packaging stay intact. It keeps grease off customers’ hands, off your counters, and off your brand. For food businesses focused on hygiene, appearance, and sustainability, it has become a go-to packaging material.

In this guide we will look at how greaseproof paper works, the different types available, and why it is more than just a liner. From functional benefits to custom branding, you will learn how this humble paper supports better packaging, better presentation, and better business.

What Is Greaseproof Paper?

Greaseproof paper is a type of food-grade paper engineered to resist oil and moisture penetration. It is commonly used in baking, food wrapping, and packaging applications where grease control is essential.

Its performance comes from a mechanical process called calendering, which compresses the paper fibers to create a dense, low-porosity surface. This structure prevents fats and liquids from seeping through. In some cases, a food-safe coating such as silicone is added to enhance heat resistance or improve release properties for baking.

While greaseproof paper performs well under moderate heat, not all types are suitable for high-temperature use. Uncoated variants may discolor, curl, or weaken in the oven. For baking or reheating, always verify temperature tolerance. Though simple in appearance, greaseproof paper is a purpose-built material designed for efficiency, hygiene, and food-safe performance.

How Greaseproof Paper Works?

The key to greaseproof paper’s performance lies in its dense fiber structure. During manufacturing, the paper undergoes a process called calendering, where rollers compress the cellulose fibers tightly together. This dramatically reduces the paper’s porosity, forming a physical barrier that blocks oil and moisture from passing through.

Its effectiveness comes from the internal structure itself, with fibers so tightly bonded that oil cannot seep between them. This makes it food-safe, clean, and reliable for various uses.

In some cases, a silicone coating is added to improve heat resistance and non-stick properties, especially for baking applications. But the core greaseproof function is structural and achieved without chemical treatment, making it both efficient and naturally effective.

How Greaseproof Paper Is Made?

The manufacturing of greaseproof paper begins with a refined blend of high-quality pulp, often combining needlewood and bamboo fibers. These raw materials are selected for their strength and flexibility, which are essential for producing paper that is both durable and resistant to oil.

The pulp is first beaten to modify the fiber surface and improve bonding. Once formed into sheets, the paper passes through heavy calendering rollers. This process compresses the fibers tightly, creating a smooth, low-porosity surface that blocks oil and moisture. The result is a base material known as glassine, which provides the structural foundation of greaseproof paper.

To further enhance its performance, the paper may be treated with natural additives such as starch, alginates, or carboxymethyl cellulose, which help fill any remaining micro-gaps and improve fat resistance. For higher-grade applications, a final surface treatment with oxidised starch or silicone adds non-stick properties and increases oven resistance.

The finished paper is then dried, polished, and trimmed. This detailed process ensures a clean, food-safe material that performs consistently in both packaging and cooking environments.

Types of Greaseproof Paper

Greaseproof paper comes in a variety of types, each offering unique advantages depending on the application, aesthetic, or sustainability goals. Below are the most common types you’ll encounter in food service and packaging.

Bleached Greaseproof Paper

Bleached greaseproof paper is white and chemically treated to remove its natural color, giving it a clean, polished appearance. It’s commonly used in branded packaging where a professional, high-contrast print is needed, such as for custom logos or pattern designs. While it’s visually appealing and widely used in cafes and bakeries, some brands are moving away from it due to environmental concerns linked to chemical processing.

Unbleached Greaseproof Paper

Unbleached greaseproof paper retains its natural brown color because it skips the bleaching process, making it a more eco-friendly choice. It’s often favored by sustainable brands, organic food vendors, and businesses seeking a rustic, natural look that aligns with environmentally conscious values.

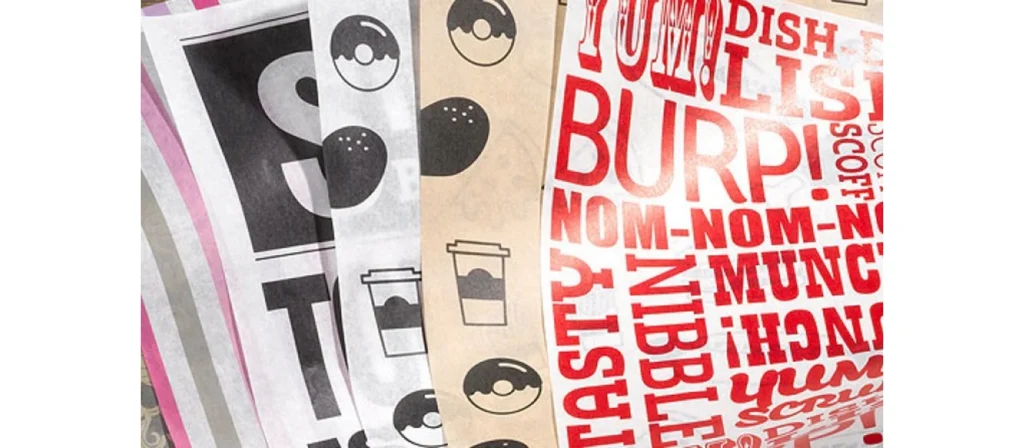

Colored and Custom-Printed Greaseproof Paper

Colored or custom-printed greaseproof paper adds a branding element to food packaging by featuring logos, patterns, or seasonal artwork. It’s popular in restaurants, delis, and bakeries aiming to create a more memorable unboxing or dining experience, while still offering effective grease resistance and food-safe performance.

PFAS-Free Greaseproof Paper

PFAS-free greaseproof paper eliminates the use of per- and polyfluoroalkyl substances, which are often added to resist grease but have raised health and environmental concerns. As consumer awareness grows, this type has become increasingly preferred by food businesses focused on offering safe, sustainable packaging solutions.

Silicone-Coated Greaseproof Paper

Silicone-coated greaseproof paper is designed for high-heat applications like baking, thanks to its excellent non-stick properties and oven safety. Often reusable, it’s the go-to choice for commercial kitchens and home bakers needing a reliable, food-safe paper that won’t burn or stick under high temperatures.

Common Uses of Greaseproof Paper

Greaseproof paper is a surprisingly versatile material used across various industries, especially in food-related settings. Its oil-resistant, moisture-blocking properties make it a go-to for everything from cooking to branding.

Baking and Cooking Applications

In baking, greaseproof paper is a staple for lining cake tins, cookie sheets, and pastry trays. It prevents sticking without the need for additional oils or sprays, making cleanup easier and baked goods look more polished. It’s also used for steaming foods like fish or dumplings, acting as a protective barrier that maintains moisture while resisting grease.

Food Wrapping and Takeaway Packaging

Greaseproof paper is widely used in food wrapping for sandwiches, burgers, fries, and pastries. It prevents oils from seeping through packaging, keeping both the food and customer hands clean. For takeaway businesses, it enhances presentation and hygiene while also serving as a branding opportunity when custom printed.

Industrial and Non-Food Uses

Beyond food, greaseproof paper plays a role in cosmetics packaging, industrial layering, and even crafting. It’s used to wrap oily skincare products or line boxes to prevent product seepage. In industrial settings, it serves as a separator between greasy components or as protective wrapping during shipping.

Benefits of Greaseproof Paper

Greaseproof paper offers more than just oil resistance. Its unique qualities make it essential for both home kitchens and food businesses. From baking trays to branded wraps, its benefits span functionality, presentation, and sustainability.

Grease and Moisture Resistance

Greaseproof paper is specially designed to resist oil and moisture, which keeps packaging clean and food presentable. It prevents soggy bottoms and greasy stains, making it perfect for baked goods, fried foods, or deli wraps. This reliability is especially important in takeaway services, where appearance and hygiene both matter.

Non-Stick Performance

With a naturally smooth surface, greaseproof paper helps prevent food from sticking to pans or trays. It’s ideal for baking cookies, pastries, and other delicate items that can tear easily. It also eliminates the need for extra oil or butter, which supports healthier cooking and easier cleanup.

Heat Resistance

Many types of greaseproof paper, especially those with silicone coatings, are oven-safe up to 220°C. They handle most baking and reheating tasks without curling, scorching, or sticking. This makes them far more versatile than wax paper and perfect for both home ovens and commercial use.

Custom Branding Potential

Greaseproof paper can be custom printed with logos, designs, or seasonal themes, turning everyday packaging into a branding opportunity. It adds a professional touch to food presentation and helps businesses build a consistent, memorable brand experience for customers.

Environmentally Friendly Options

Sustainable greaseproof paper options, such as unbleached or PFAS-free types, are increasingly popular. Many are biodegradable, compostable, or recyclable. Choosing eco-friendly paper shows environmental responsibility and aligns with growing consumer demand for greener packaging choices.

Greaseproof Paper vs. Other Food Papers

Greaseproof paper often gets confused with other types of food-grade paper, like wax paper, parchment paper, or butcher paper. While they may look similar at first glance, each has specific properties and best-use scenarios. Choosing the right one can make a big difference in food safety, presentation, and performance.

Below is a detailed comparison to help you understand how greaseproof paper stands apart.

Comparison Table: Greaseproof Paper vs. Other Food Papers

| Paper Type | Grease Resistance | Heat Resistance | Non-Stick | Typical Use Cases |

|---|---|---|---|---|

| Greaseproof Paper | High | Moderate to High | Moderate to High | Wrapping baked goods, lining trays |

| Parchment Paper | High | High | High | Baking, roasting, non-stick cooking |

| Wax Paper | Moderate | Low | Moderate | Cold food wrapping, cheese storage |

| Butcher Paper | Low to Moderate | Low | Low | Meat wrapping, deli use, crafts |

Key Differences Explained

Greaseproof paper is designed mainly for oil resistance and light to moderate heat tasks. It’s best for wrapping greasy foods or lining trays, especially in bakeries and takeout. It doesn’t melt or break down easily, making it ideal for food packaging.

Parchment paper, often confused with greaseproof, is typically coated with silicone, which gives it superior non-stick properties and high heat tolerance. It’s perfect for baking cookies or roasting vegetables in the oven.

Wax paper has a thin wax coating that makes it moisture-resistant but not heat-safe. It will melt or catch fire in the oven. It’s great for wrapping cold foods like sandwiches, cheese, or candy.

Butcher paper is thicker and more fibrous, used mainly for wrapping meats or deli items. It doesn’t resist grease or heat well but is breathable, which helps with storing and aging meat.

Understanding these differences helps prevent kitchen mishaps and ensures you use the right material for each job. When in doubt, always check the label for heat resistance and food-safe usage.

Why Trust Million Pack for Custom Greaseproof Paper Packaging?

Million Pack is a trusted supplier of greaseproof paper, helping businesses create packaging that is both functional and brand-enhancing. With expertise in food-grade materials, they offer a wide range of options including unbleached, colored, PFAS free, and heat resistant papers.

What makes Million Pack stand out is their ability to customize greaseproof paper with logos, patterns, and designs using food safe and environmentally friendly inks. Whether you are a small café or a large food brand, they tailor solutions to match your needs both visually and technically.

With reliable production, fast turnaround times, and global shipping, Million Pack is a dependable partner for food businesses seeking high quality, sustainable, and personalized packaging that strengthens their brand.

Ready to Upgrade Your Food Packaging?

Looking for greaseproof paper that matches your food, your brand, and your sustainability goals? Million Pack offers custom solutions for bakeries, cafés, and food businesses of all sizes. From eco-friendly materials to full-color printing, we help you turn everyday packaging into a professional experience. Contact us today to request samples, get a quote, or explore custom printing options tailored to your business.

Get a Quote

Get a Quote

FAQs

Is greaseproof paper the same as butter paper?

Not always. “Butter paper” is a loose term that may refer to greaseproof or wax paper depending on the region. Greaseproof paper resists oil without wax coating, unlike wax paper.

What’s a substitute for greaseproof paper?

Parchment paper is the most common substitute, especially for baking. For cold or greasy food wrapping, wax paper or foil may also work depending on the use case.

Do you have to use greaseproof paper when baking a cake?

No, but it helps. Greaseproof paper prevents sticking and makes cake release cleaner, especially with delicate sponge cakes or when you want smooth edges.

Is greaseproof paper white or brown?

It can be either. White (bleached) versions are chemically treated for a clean appearance, while brown (unbleached) paper is more natural and often marketed as eco-friendly.

How to stop greaseproof paper from sticking?

Use the coated or treated side facing the food if applicable. In baking, ensure surfaces are clean and dry, and consider a light oil spray for extra release.

Why can’t you use greaseproof paper in the oven?

You actually can, but only if it’s rated for oven use. Some low-grade or non-coated types may smoke, curl, or break down at high temperatures above 200°C.

Is parchment paper like greaseproof paper?

They’re similar in oil resistance, but parchment paper is typically silicone-coated, making it better for high-heat, non-stick baking. Greaseproof paper may not perform as well at high temperatures.