When consumers have clear guidance on how to dispose of paper plates, they make correct choices with confidence. Businesses also benefit from this clarity because they can select suppliers knowing their products meet regulatory expectations and growing customer demand for sustainability. This level of certainty supports a stronger brand image, reduces unnecessary waste, and helps companies present themselves as leaders in environmental responsibility within a competitive market.

This guide is your bridge from confusion to confident, strategic action. We will demystify the rules of paper plate recycling for everyone, from households to procurement managers. You will learn to identify truly recyclable materials, understand the impact of common contaminants, and discover actionable tips for choosing products that genuinely support a circular economy and enhance your sustainability commitments.

What Makes Paper Plates Recyclable

Understanding what makes a paper plate recyclable helps you recognize which products can enter the recycling stream and which cannot. Different materials and coatings behave differently during pulping, so identifying these traits matters. This section explains the essential features that support the recycling process.

Fiber Quality

Paper plates start with wood fiber, and the recyclability of those fibers is the first deciding factor. Clean, strong fibers break down easily in pulping machines and can be reused to create new paper. Plates made from thick paperboard or molded fiber usually provide this level of quality. When the fibers are consistent and free from non-paper layers, mills can turn them into usable recycled pulp.

Simple Plate Construction

A plate that qualifies as Recyclable Paper Plates must be primarily paper. If the structure hides plastic, foam, or metallic sheets inside, the plate fails during pulping. Single-material construction works best because recycling facilities depend on machinery designed for fiber, not mixed materials. A plate that tears cleanly and shows only paper fibers along the edge is usually a positive sign.

Lightweight Coatings

Many plates have coatings to keep liquid or oil from soaking through. These coatings determine whether the plate can be accepted into the recycling flow. Light mineral or thin plastic coatings can sometimes be screened out during pulping, allowing the fiber to be reused. Heavy coatings behave like separate materials and often cause mills to reject the plate entirely.

Clean Surface Condition

The final answer to Are Paper Plates Recyclable often depends on how the plate was used. A plate that held dry food may remain clean enough for recycling, while one covered in oil or sauce may not. Grease binds with fibers and creates clumps that interfere with the screening process. Recycling plants cannot remove oily residue effectively, which results in contamination of the batch.

- Clean Surface Condition

- Lightweight Coatings

- Simple Plate Construction

- Fiber Quality

When a paper plate contains clean fibers, simple construction, minimal coatings, and little contamination, it is most likely to be recyclable. Knowing these traits makes it easier to choose products that truly support sustainable waste management and clarifies which plates belong in recycling and which do not.

Why Some Paper Plates Can’t Be Recycled

Not all plates that appear to be paper actually behave like recyclable products. Some contain materials or residues that disrupt the pulping process. This section explains the most common reasons paper plates are rejected by recycling programs.

Common Reasons Paper Plates Are Rejected From Recycling

- Grease and food residue: Oil and sauce penetrate the fibers and cannot be washed out. When mills process greasy material, the pulp becomes weak and sticky, which can affect entire recycling loads.

- Thick plastic linings: Some plates contain dense plastic layers that do not break down during pulping. These layers clog screening equipment and are treated as contaminants even when the plate looks like paper from the outside.

- Multi layer designs: Plates made with fused layers of paper, plastic, or metallic materials are difficult to separate during recycling. These mixed structures interfere with pulping and are often rejected at sorting facilities.

- Heavy wet strength chemicals: Plates designed to hold soups or very moist foods contain treatments that resist pulping. Many mills cannot process these fibers, so they decline this material.

- Decorative printing: Plates with saturated inks or metallic pigments can leave residue in the pulp. Dark or heavily printed surfaces may stain recycled material, reducing quality and limiting acceptance.

- Compostable misunderstanding: Some plates labeled compostable cannot be recycled. Compostable coatings behave differently during pulping and disrupt recycling systems. These products must be composted rather than recycled.

In summary, the following six situations require that paper plates not be recycled.

- Grease-soaked plates

- Thick plastic-lined plates

- Multi-layer composite plates

- Wet-strength treated plates

- Heavily printed decorative plates

- Compostable bioplastic-coated plates

Recycling failures usually happen because of coating, contamination, or incorrect labeling. By understanding these barriers, households and businesses can avoid placing unsuitable plates into recycling bins. Clear decisions help protect recycling streams and improve overall material recovery.

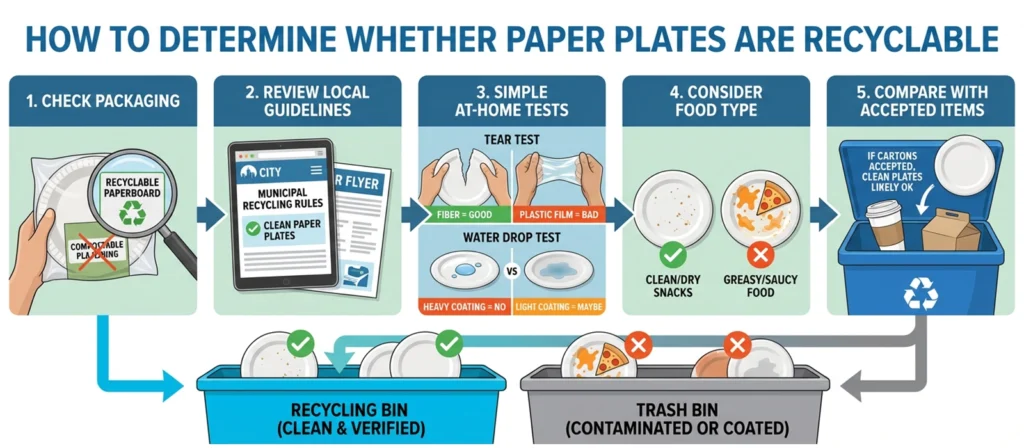

How to Determine Whether Paper Plates Are Recyclable

Many people wonder whether their plates belong in the recycling bin, yet the answer depends on specific clues. By checking the material, local rules, and the condition of the plate, you can judge whether your item qualifies. This section offers simple steps anyone can follow.

How to Tell Whether Your Paper Plates Are Recyclable

- Check the packaging: Clear labeling provides the most reliable guidance. Packaging that states compatibility with curbside paper recycling reflects testing and verification. Generic eco claims are not enough, and missing labels usually signal that recycling is not advised.

- Review local guidelines: Recycling rules vary by location. Many guides list paper plates separately and note whether clean plates are accepted. If your municipality excludes plates, the answer in your area is likely no. Local instructions should always guide your decision.

- Use simple at home tests: When information is unclear, tearing the plate can reveal hidden plastic layers. A clean tear that resembles cardboard indicates pure fiber, while visible plastic strands suggest coatings that interfere with recycling. A small water drop test also shows whether coatings are heavy or light.

- Consider the type of food used: Clean, dry plates may remain suitable for recycling. Plates exposed to grease, melted cheese, or sauces usually cannot be recycled because food residue contaminates the pulp even when the material itself is recyclable.

- Compare with accepted items: If your facility accepts paper cups or coated food containers, similar paper plates may also qualify. If these items are excluded, plates often follow the same rule. Visual comparison helps you judge whether your plate matches materials your facility already processes.

With simple checks, consumers can make confident decisions about plate disposal. These steps reduce contamination and support recycling facilities that depend on clean, fiber-rich streams. Consistent use of these methods strengthens overall recycling efficiency.

Types of Paper Plates That Can Be Recycled

Not all plates are made the same, and some are naturally more compatible with recycling systems. This section breaks down the main types that may qualify, depending on material and local acceptance.

1. Uncoated Paperboard Plates

These plates contain pure fiber without added barriers and offer the cleanest material stream for mills. They work best with dry snacks or light meals and break down quickly during pulping without leaving residue. Because their structure mirrors standard cardboard, most facilities can process them easily when local programs accept plates as part of regular paper recycling.

2. Plates with Biodegradable Plastic Coatings

Some plates use thin biodegradable coatings such as PLA, PHA, or PBS that provide moisture resistance while still allowing mills to recover most of the fiber. These coatings are applied in lightweight layers, often supported by mineral or water-based dispersion technology that can be screened out during pulping. Although performance improves with these materials, recyclability still depends on local programs that accept coated paperboard.

3. Bagasse Plates

Plates made from molded plant fiber or sugarcane bagasse provide strong cellulose content that behaves similarly to paper in most pulping environments. When produced without extra barrier films, they can integrate well into recycling systems and deliver high-fiber yield. Some areas classify them as compostable instead, so their final path depends on the capability of local recycling or composting facilities.

Comparison of Different Paper Plate Types

To better understand the characteristics and disposal methods of different paper plates, please refer to the table below:

| Plate Type | Key Characteristics | Recyclability | Best Disposal Method |

|---|---|---|---|

| Uncoated Paperboard Plates | Pure plant fiber, no coating, similar to cardboard. | High | Place in paper recycling bin, provided it’s clean and dry. |

| Plates with Biodegradable Plastic Coatings | Thin coatings (e.g., PLA, PHA) for moisture resistance. | Medium | Depends on local recycling facilities’ acceptance of coated paperboard. |

| Bagasse Plates | Made from molded plant fibers like sugarcane bagasse. | Medium | Depends on local regulations; may be recyclable or compostable. |

| Compostable Fiber Plates | Explicitly labeled “compostable,” often with bioplastic coatings. | Almost Zero | Industrial composting system (not standard recycling bin). |

| Plates with Thick Plastic Linings | Internal, smooth, tear-resistant plastic lining for strong waterproofing. | Very Low | Difficult to separate paper from plastic; usually non-recyclable, dispose of as general waste. |

| Heavily Printed or Metallic-Coated Plates | Decorated with saturated inks, metallic pigments, or metallic layers. | Very Low | Inks and metallic layers do not dissolve easily and can contaminate pulp; dispose of as general waste. |

Understanding the differences among plate types helps consumers choose options that truly support recycling. Selecting the right product reduces waste and increases the likelihood that valuable fiber is recovered. This knowledge also supports businesses seeking sustainable packaging choices.

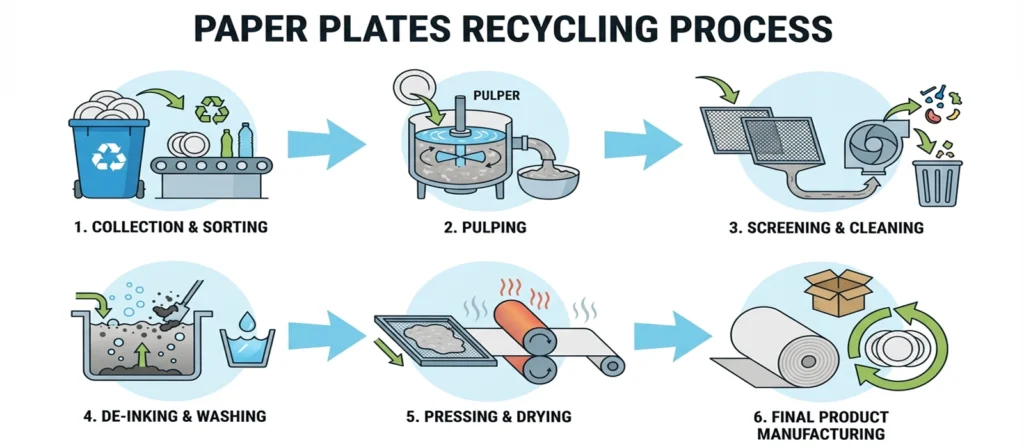

Paper Plates Recycling Process

The journey of a recyclable paper plate from your bin to a new product involves several crucial steps.

- Collection and Sorting: Recyclable paper plates are collected and transported to a Materials Recovery Facility (MRF). Here, they are sorted manually or by machines to separate them from other recyclables like plastic and glass, and to remove heavily contaminated items.

- Pulping: The sorted plates are placed into a large vat called a ‘pulper,’ where they are mixed with water and chemicals. High-speed rotating blades break them down into their original components—cellulose fibers—forming a thick slurry.

- Screening and Cleaning: The pulp is passed through a series of screens of various sizes to remove non-fiber contaminants like plastic coatings, food scraps, and staples. Centrifugal cleaners use rotational force to separate heavy contaminants that are denser than the fibers.

- De-inking and Washing: If the plates have ink, the pulp is sent to a de-inking system. Air and chemicals are injected, causing ink particles to attach to bubbles and float to the surface, where they are scraped off. Afterward, the pulp is thoroughly washed to remove any remaining chemicals.

- Pressing and Drying: The clean pulp is pumped onto a paper machine and spread over a moving screen, where most of the water is drained. The pulp layer then passes through a series of large, heated press rollers that squeeze out more water and dry it, ultimately forming a continuous sheet of recycled paper.

- Final Product Manufacturing: The dried recycled paper is wound into giant rolls. These rolls are then sold as raw material to manufacturers to produce new paperboard, packaging boxes, toilet paper, or other paper products, completing the recycling loop.

This efficient process ensures that valuable paper fibers are reused, contributing to a more sustainable cycle.

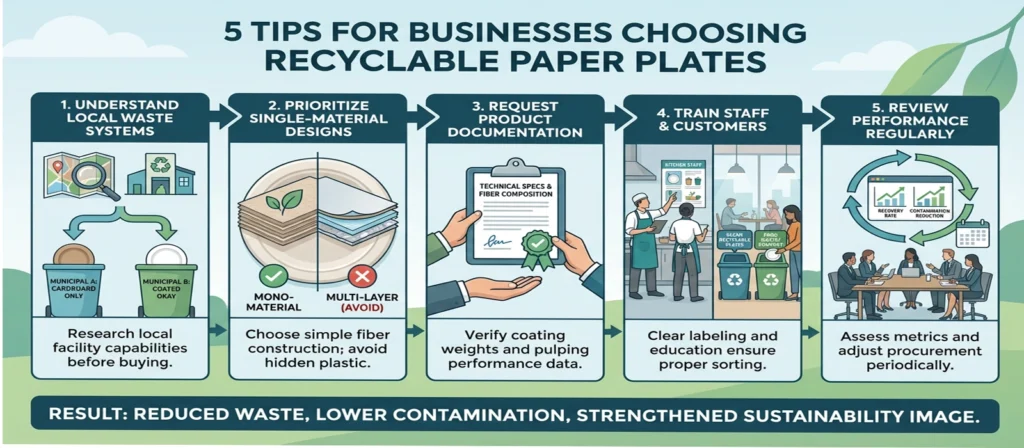

5 Tips for Businesses Choosing Recyclable Paper Plates

Businesses have a larger environmental footprint and therefore must choose plate materials responsibly. The right selections reduce contamination, support recycling goals, and strengthen sustainability commitments.

Tip 1: Understand Local Waste Systems

Businesses should begin by studying how their local facilities process food service packaging. Some cities accept only cardboard, while others accept coated paperboard. Understanding local capacity prevents purchasing products that cannot enter recycling streams even if labeled recyclable.

Tip 2: Prioritize Single-Material Designs

Choosing plates with simple fiber construction reduces recycling risks. Mono-material plates without hidden plastic layers are more likely to be accepted by mills. These products may not resist heavy moisture as well as multi-layer plates, but they guarantee higher recycling compatibility.

Tip 3: Request Product Documentation

Suppliers offering reliable Recyclable Paper Plates usually provide technical documents explaining coating weight, fiber composition, and pulping performance. Asking for verification ensures your purchase aligns with genuine recycling processes rather than relying on vague marketing statements.

Tip 4: Train Staff and Customers

Clear internal communication is essential. Employees handling food waste should understand how to sort plates properly. Businesses can support guests by placing well-labeled bins in dining areas. Even a high-quality recyclable plate fails when incorrectly discarded.

Tip 5: Review Performance Regularly

Monitoring waste data helps businesses refine their sustainability approach. If recyclable plates repeatedly end up in trash or create contamination issues, adjustments may be needed. Evaluating customer behavior, menu choices, and product performance leads to better waste outcomes.

Businesses that make informed choices contribute meaningfully to recycling efficiency. By selecting appropriate products and educating staff, companies strengthen their environmental performance. These practices ensure that Recyclable Paper Plates are handled correctly across operations.

Why are more and more companies choosing recyclable paper trays?

The primary driver behind this shift is rising consumer awareness. Today’s customers are increasingly eco-conscious and actively support businesses that demonstrate environmental responsibility. By offering sustainable paper plates, companies can meet this demand, enhance their brand image, and foster customer loyalty, creating a positive reputation that sets them apart from the competition.

Simultaneously, governments worldwide are tightening regulations on single-use plastics. The introduction of bans, taxes, and other restrictions makes switching to sustainable alternatives a matter of operational necessity. Businesses that adopt compostable or recyclable plates proactively ensure they remain compliant, avoiding potential fines and operational disruptions.

Ultimately, choosing sustainable paper plates is a strategic business decision that signals a commitment to long-term sustainability and market leadership. This forward-thinking approach not only mitigates risks associated with environmental regulations but also positions the brand as a responsible leader in a rapidly evolving market, attracting both customers and talent who value sustainability.

- Meet Consumer Demand

- Enhance Brand Image

- Adhere to Regulations

- Strengthen Corporate Responsibility

- Gain a Competitive Edge

Recyclable paper plates are arguably one of the most important products you must pay attention to and consider using.

Conclusion

The question Are Paper Plates Recyclable has more than one answer. Some plates contain clean paper fiber that mills can reuse. Others include coatings, inks or contamination that prevent recycling entirely. Local facility capability also determines whether a product is accepted or rejected. With careful attention to materials, usage, cleanliness and local rules, households and businesses can confidently choose Recyclable Paper Plates and dispose of them responsibly.

FAQs

1. Can I recycle a paper plate if it only has a small amount of grease or food crumbs on it?

No. Any plate with grease or oily residue is not recyclable because the oil contaminates the paper fibers.

Dry crumbs on an otherwise clean plate are usually acceptable if your local program allows plates.

Once you see visible grease stains, the plate should go in the trash or compost instead of recycling.

2. How can I tell if a paper plate has a plastic coating that makes it non recyclable?

Try tearing the plate gently and look at the torn edge.

If it tears cleanly like plain paper or cardboard, it is more likely to be recyclable.

If you see a plastic film that stretches or resists tearing, the plate has a coating and should not be recycled.

3. What is the difference between “compostable” and “recyclable” plates, and why can’t I recycle a compostable one?

Recyclable plates are designed to be turned back into paper pulp and made into new paper products.

Compostable plates are made to break down in an industrial composting facility, not in a paper mill.

The materials in compostable plates can contaminate the paper recycling stream, so they must be composted instead of recycled.

4. Why is grease such a major problem that it makes an otherwise recyclable paper plate unusable?

Grease does not separate from paper fibers during the pulping process.

Oily fibers create weak, sticky pulp that cannot be turned into strong, clean recycled paper.

Even a small amount of grease can affect a larger batch, which is why recycling programs reject greasy plates.

5. If a paper plate is clean and seems to be made of simple paperboard, is it always safe to put it in the recycling bin?

No, not always. A clean paperboard plate is only one part of the decision.

The most important step is to check your local recycling guidelines and see if they accept paper plates at all.

Some programs do not allow any kind of paper plates, even when they look clean and recyclable.