Matte Finish vs Glossy Finish for Packaging offers very different qualities. Matte feels smooth, understated, and elegant, often used to signal simplicity or sophistication. Glossy finishes are eye-catching and bright, making colors appear richer and more vibrant. Each finish can change the way your design is perceived, not only on shelves but in the hands of the customer.

Packaging does more than protect what is inside. It creates a first impression, sets expectations, and tells a story before a single word is read. When it comes to visual appeal and tactile experience, the choice between a matte finish and a glossy finish can make all the difference. This decision is subtle but powerful, influencing how your product is seen and felt, often in just a second or two.

Picture a single-wall coffee cup from a busy corner shop, finished in a plain matte coating. It feels practical, no nonsense, and built for takeaway speed. Now contrast that with a double-wall cup from an upscale café, wrapped in a glossy finish that reflects light and shows off the logo in sharp, vibrant color. It feels more premium, more deliberate, almost like part of the experience rather than just a container. These are not random design choices. They are strategic decisions shaped by how finish affects perception, comfort, and brand image. In the sections ahead we will explore exactly how matte and glossy finishes perform across key areas of packaging design.

Understand Lamination and Coating

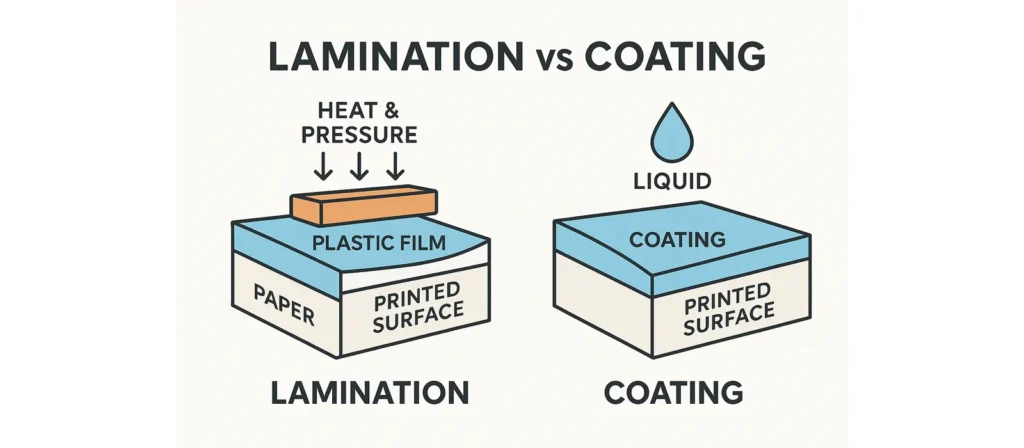

In packaging, the terms lamination and coating often come up when discussing surface finishes. While they both serve to protect printed materials and enhance the visual appeal of packaging, they differ in how they’re applied and the kind of protection they offer. Lamination involves bonding a thin layer of plastic film over the printed surface using heat and pressure. This creates a strong barrier against moisture, scratches, and general wear, making it ideal for packaging that needs durability. On the other hand, coating is typically a liquid solution, like aqueous, UV, or varnish, that’s applied directly to the paper surface and then dried or cured. It offers a lighter protective layer and is often more cost-effective.

Both matte and glossy finishes can be achieved through either lamination or coating. For example, you might use matte lamination to get a smooth, non-reflective finish that resists fingerprints and has a soft touch. Or you could use a gloss UV coating to create a shiny, high-contrast effect that makes colors pop. The method chosen often depends on the intended use, budget, and the type of packaging material involved. Understanding the difference between lamination and coating is key to choosing the right finish, not just for how it looks, but how it performs in real-world conditions.

What is Matte Finish?

A matte finish is characterized by its non-reflective, flat surface that diffuses light rather than bouncing it back. The result is a smooth, muted appearance that feels soft to the touch and reduces glare. Matte finishes are often chosen for high-end or minimalist packaging, where subtlety and elegance are part of the brand’s appeal. They can be created using matte lamination or matte coating, each offering different levels of durability and texture.

Matte can be achieved through different production methods, most commonly matte lamination or matte coating. Matte lamination involves applying a thin film over the surface using heat and pressure, while matte coating typically uses a liquid applied directly onto the substrate and cured. The final result depends on the type of material used, as well as the thickness and quality of the application process.

What is Gloss Finish?

A gloss finish is smooth, shiny, and highly reflective. It enhances color vibrancy, increases contrast, and gives packaging a clean, polished look. This finish is often associated with energy, brightness, and mass-market appeal. It can be applied via gloss lamination or gloss coating, with each method providing varying levels of sheen and durability.

Gloss lamination adds a thin, transparent film over the surface, while gloss coating involves the use of liquid solutions like UV or aqueous coatings. These are cured or dried to create a smooth, shiny top layer. Glossy finishes are popular in industries like beverages, personal care, and tech accessories, where visual impact on shelves is a top priority. On the downside, gloss finishes can show fingerprints and scuffs more easily and may produce glare under strong lighting. But when the goal is to stand out quickly and boldly, gloss often wins.

Difference Between Matte and Glossy Finishing Effect

Appearance

Matte and glossy finishes differ first and foremost in how they present the surface of the packaging. A matte finish gives a flat, non-reflective look that absorbs light, resulting in a more muted and subdued appearance. It tends to soften sharp lines and reduce the visual intensity of printed graphics. This creates a calm and refined visual tone that pairs well with minimalist or premium branding.

In contrast, a glossy finish offers a highly reflective surface that amplifies brightness and contrast. It creates a slick, polished appearance that tends to catch the eye quickly. The shine adds a sense of sharpness and depth to design elements, making packaging look bold and high-energy. This visual style is especially effective in crowded retail environments where attention is limited.

Surface Reflection

Surface reflection is a technical but important distinction. Glossy finishes reflect light directly, often producing sharp highlights and shiny hotspots depending on viewing angle and light source. This reflective property can enhance visual drama but also creates variability depending on where the product is placed.

Matte finishes, by contrast, diffuse light evenly across the surface. This means there is little to no shine, and the surface looks consistent under different lighting conditions. It avoids reflections altogether, maintaining a stable appearance from all angles. This makes matte surfaces easier to photograph or display under bright lights without distractions.

Usability

In terms of practical use, matte finishes tend to be more forgiving in high-contact scenarios. They do not show fingerprints, smudges, or minor scratches easily, which helps maintain a clean look even after repeated handling. This makes them suitable for products meant to be touched frequently, such as takeaway packaging or interactive printed materials.

Glossy finishes are less resistant to marks. Their smooth, shiny surface often highlights fingerprints, dust, and even light abrasions. While they look pristine when untouched, frequent contact can diminish their visual quality unless additional protective measures are applied. They are often used for packaging meant to remain sealed or displayed without heavy interaction.

Color Vibrancy

Glossy finishes naturally enhance color vibrancy. They deepen blacks, intensify saturation, and make lighter tones more vivid. This is due to the way gloss reflects light, which increases contrast and sharpness. Graphics and photos appear bolder and more eye-catching, making this finish ideal for designs that rely on visual punch.

Matte finishes tend to soften color output. They absorb more light and reduce the intensity of both dark and bright tones, resulting in a more neutral or understated look. While this can slightly dull high-saturation designs, it often benefits detailed artwork or packaging that prioritizes subtlety over impact.

Glare & Readability

Glare is often overlooked but critically affects readability. Glossy surfaces, with their high reflectivity, are more prone to glare under overhead lighting or sunlight. This can make printed text or images difficult to see from certain angles. It’s particularly noticeable on flat surfaces, like brochures, labels, or book covers.

Matte finishes significantly reduce glare due to their light-diffusing properties. Text and design elements remain legible in a wide range of lighting environments, making them ideal for informational packaging or printed material that needs to be read easily. This clarity is especially helpful for small text or detailed layouts.

Tactile Feel

The feel of a package often influences how people perceive its quality. Matte finishes offer a soft, almost velvety texture. The surface has slight resistance, which creates a warm, comfortable sensation when held. This tactile experience is often associated with luxury, minimalism, or hand-crafted quality.

Glossy finishes, on the other hand, are smooth and slick. They feel cooler and glide easily under the fingers. This can give the impression of cleanliness, speed, or high technology. While the texture is less nuanced than matte, it reinforces a sense of polish and precision, which works well for modern, high-contrast brand aesthetics.

Matte Finish vs Glossy Finish for Packaging

The table below compares matte and glossy finishes across several technical and performance-based attributes commonly considered in packaging design:

| Aspect | Matte Finish | Gloss Finish |

|---|---|---|

| Durability | Generally strong, especially with lamination; resists scratches and smudges. | Also durable but more prone to showing scratches and wear over time. |

| Print Effect | Softens colors and reduces contrast; better for subtle or minimal designs. | Enhances colors with sharp contrast and brightness; ideal for bold visuals. |

| Material Flexibility | Slightly more flexible; works well with textured or uncoated surfaces. | Slightly stiffer; better suited for smooth, coated papers or films. |

| Water Resistance | Offers good resistance when laminated; coatings provide limited protection. | High resistance, especially with gloss lamination or UV gloss coating. |

| UV Resistance | Moderate UV protection depending on material and method used. | Often higher UV resistance, especially with UV coatings. |

| Temperature Resistance | Performs well under moderate temperature shifts; stable matte surfaces. | Gloss layers may warp slightly under heat but remain stable in cold storage. |

| Cost | Slightly more expensive in lamination due to texture finish. | Usually more cost-effective in coating applications. |

| Eco Compatibility | Available in eco-friendly options; some matte films are biodegradable. | Also available in recyclable variants but less common in high-gloss laminates. |

Use of Matte and Gloss Finishes in Various Industries

Food Packaging

Matte finishes are commonly used on takeaway boxes, bowls, and paper containers designed for casual or fast-casual dining. The soft, non-reflective surface feels more natural and often pairs better with kraft or compostable materials. It also avoids glare under indoor lighting, making product labels or branding easier to read at the counter or table.

Glossy finishes, on the other hand, are more frequently applied to double-wall coffee cups, printed lids, or promotional packaging meant to catch attention. The high shine enhances visual contrast, making logos and colors stand out. For example, a gloss-laminated cold cup can give a cleaner, more vibrant impression at a café, especially for iced drinks or branded events.

Finish selection in food packaging often comes down to the balance between practical use, material compatibility, and the brand story the packaging needs to tell. For eco-conscious brands, matte finishes on biodegradable materials provide a cleaner aesthetic that aligns with sustainability goals without compromising performance.

Luxury Products

In luxury packaging, the finish is part of the product experience. Whether it is a box of artisan chocolates, a skincare gift set, or a bottle of wine, the texture and look of the package must align with a sense of exclusivity. Matte and glossy finishes are both used in this space, but for different emotional effects.

Glossy finishes often give packaging a high impact, glamorous appearance. They enhance bold colors, reflect light, and amplify printed elements, which is ideal for creating a strong first impression. Matte finishes, on the other hand, offer a more subtle sophistication. Their smooth, non-reflective surface feels refined, minimal, and deliberate. A matte black box with soft touch lamination can feel just as premium as a high gloss counterpart, but with a quieter kind of elegance. In many luxury applications, brands choose based on the type of statement they want to make, whether bold and energetic or calm and confident. Both finishes aim to elevate the unboxing experience.

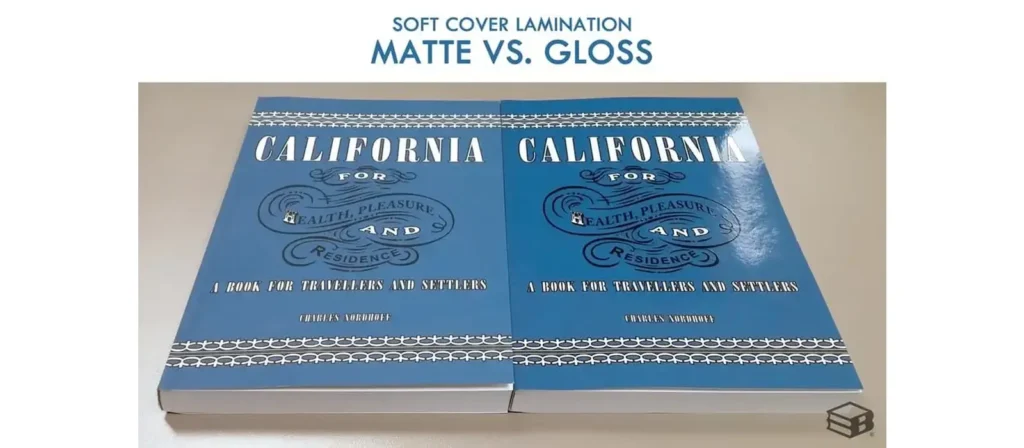

Books and Journals

In publishing, the choice between matte and glossy finishes often depends on content type and reader experience. Glossy covers are common for magazines, catalogs, or photography books where color sharpness and visual impact matter. Matte finishes are more frequently used for novels, journals, children’s coloring books,and academic publications, where readability and a softer tactile feel are preferred. Matte also resists glare under reading lights, making it easier on the eyes during extended use.

Business Cards

Business cards are a small format with high design stakes. Glossy finishes are used when bold colors, photographs, or vibrant logos are part of the layout. They offer a polished and attention-grabbing look. Matte finishes, on the other hand, provide a more sophisticated and modern feel, and they are often easier to write on. Professionals seeking a minimalist, premium impression tend to favor matte, while glossy works well for brands that lean toward dynamic visuals.

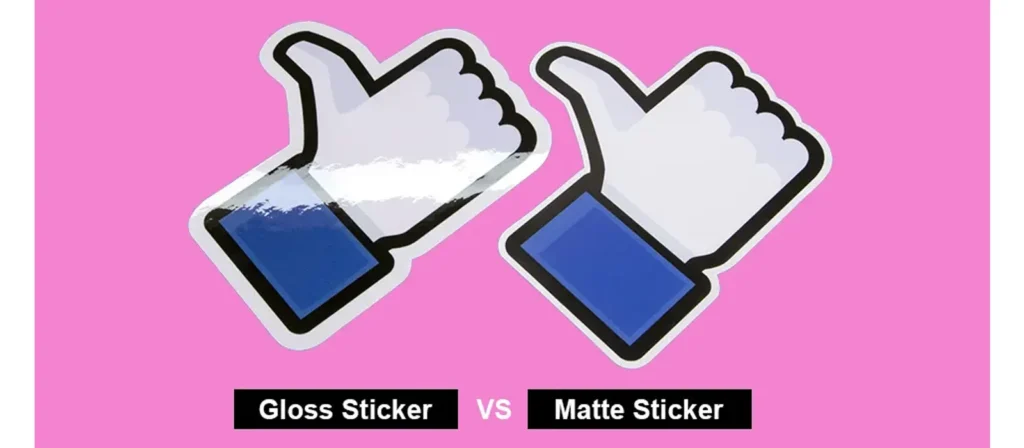

Custom Stickers

For stickers, both finishes are widely used based on their purpose. Glossy stickers are bright, durable, and ideal for product labeling or promotional use, especially when color visibility is key. Matte stickers have a softer look and are popular for boutique branding, eco packaging, and items where a less reflective surface is desired. The finish also affects how well a sticker blends with packaging, whether you want it to stand out or blend in.

Advantages and disadvantages of Matte Finish

Matte finishes are commonly used across industries for their elegant appearance and comfortable feel. While they offer a refined aesthetic and functional benefits, they are not always the best choice for every packaging need. Below are the key strengths and limitations of matte finishes.

Pros

- Reduces glare and enhances readability under different lighting conditions

- Provides a soft, smooth texture that feels premium and natural

- Resists fingerprints and smudges on high-touch surfaces

- Works well with muted color palettes and minimalist design

- Ideal for eco-friendly materials and sustainable branding

Cons

- Slightly mutes colors and reduces overall print vibrancy

- May appear flat or dull for highly graphic or colorful designs

- Less water-resistant than high-gloss coatings if not laminated

- Can be more expensive when using specialty matte laminations

- Texture may show scuffs over time on certain substrates

Advantages and disadvantages of Gloss Finish

Gloss lamination is often used to create a clean, vibrant surface that stands out visually. Its high reflectivity and smooth texture make it a popular choice in commercial packaging, but it also comes with trade-offs depending on how and where it is used.

Pros

- Enhances color depth and sharpness for bold visual impact

- Creates a sleek, polished surface that looks clean and modern

- Offers strong resistance to moisture and external elements

- Adds a smooth finish that pairs well with detailed graphics

- Suitable for products that need to stand out quickly on shelves

Cons

- Shows fingerprints, scratches, and dust more easily

- Can create glare under lighting that affects readability

- Feels less natural or soft compared to matte finishes

- May not bond as well with some textured or uncoated papers

- High-gloss lamination is not always ideal for eco-conscious brands

Choose the Right One for Packaging

Choosing between matte and glossy finishes depends on more than just visual preference. The product type, target audience, and how the packaging will be handled all play important roles in making the right decision. Each finish offers its own set of characteristics that support different design goals.

Gloss finishes are ideal when strong visual impact and color intensity are priorities. They work well for promotional materials, tech accessories, or packaging that needs to grab attention quickly. Matte finishes, on the other hand, provide a softer, more natural look that supports minimalist branding and offers a tactile, premium feel.

In food packaging, both finishes have their place. A double-wall coffee cup might use a glossy surface to highlight brand colors, while a kraft takeaway box benefits from a matte finish that aligns with eco values and reduces glare. Ultimately, the right choice depends on the balance between visual appeal, practicality, and how well the finish supports your brand story.

Conclusion

The finish you choose for your packaging does more than complete the look. It shapes how people interact with your brand from the very first moment. Matte and glossy finishes each bring distinct qualities, from the way they handle color and texture to how they perform under lighting or frequent handling. Neither is objectively better than the other. What matters is how well the finish supports the function, message, and style of your product.

For brands in the food industry and beyond, understanding these differences is key to making informed decisions that align with customer expectations and packaging needs. Whether you are aiming for a bold high gloss design or a calm matte surface that speaks to sustainability and subtlety, the finish should feel intentional and on brand. When chosen thoughtfully, it becomes part of the product experience, not just a protective layer but a statement in itself.