PFAS Free Food Packaging has become a priority for businesses and consumers who want safer and more sustainable choices. Growing awareness of chemical exposure has created a need for packaging solutions that protect both people and the environment. Companies are now expected to understand what PFAS are and how to eliminate them from their supply chain.

This shift sets the stage for a deeper exploration of what PFAS are, why they pose risks and how businesses can transition to safer materials. The following sections break down their chemistry, common uses and the emerging alternatives that define the future of responsible food packaging.

What is PFAS?

The acronym PFAS refers to Per and Polyfluoroalkyl Substances. These are a large group of manmade chemicals that have been in use across various industrial and consumer products since the 1940s. Their chemical structure gives them unique properties that make them highly valuable for specific applications. Crucially, PFAS contain a chain of carbon atoms bonded to fluorine atoms. The carbon fluorine bond is one of the strongest in organic chemistry, which is the very reason these chemicals earned their notorious nickname.

Defining Per and Polyfluoroalkyl Substances The “Forever Chemicals”

PFAS are commonly known as “forever chemicals” because of their extreme persistence in the environment and in the human body. Unlike many other compounds, PFAS do not naturally degrade over time. When they are released into the air, water, or soil, they remain intact, leading to bioaccumulation. This means that as they enter the food chain, the concentration of these substances increases up the trophic levels. The stability that makes them useful in manufacturing is the same characteristic that makes them a long term global contaminant. Understanding the chemistry behind this stability is the first step toward appreciating the necessity of PFAS Free Food Packaging.

Understanding the Health and Environmental Risks

The widespread use of PFAS and their environmental persistence have led to significant concerns regarding human health. While research is ongoing, many studies have linked exposure to various health issues. The key problem is the accumulation of these chemicals in the blood, organs, and tissues of living beings.

The U.S. Environmental Protection Agency EPA and health organizations worldwide have pointed to several potential adverse effects associated with PFAS exposure:

Potential health risks associated with PFAS exposure include:

- Increased risk of certain cancers, including kidney and testicular cancer

- Hormonal disruption and interference with the body’s endocrine system

- Immune system suppression, reducing the effectiveness of vaccines

- Impacts on cholesterol levels and liver function

- Developmental effects in children and decreased fertility

The transition to PFAS Free Food Packaging is therefore not merely a compliance issue, but a major public health measure aimed at eliminating one pervasive source of exposure to these harmful chemicals. The environmental consequence is equally severe. Manufacturing facilities release PFAS into waterways, contaminating drinking water sources and accumulating in landfill leachates, contributing to a persistent environmental burden.

The Common Uses of PFAS in Traditional Food Packaging

In the context of food service and distribution, PFAS were traditionally added to materials to provide an unparalleled level of resistance to water, oil, and heat. The chemical barrier they created meant that a simple paper plate could hold greasy French fries or a hot, saucy meal without soaking through.

These chemicals were particularly prevalent in molded fiber products such as clamshell containers and bowls, as well as in greaseproof paper used for wraps and linings. The goal was superior performance, offering convenience and preventing leaks that consumers found frustrating.

Common food packaging items that historically contained PFAS include:

- Molded fiber containers used for takeout meals

- Grease resistant paper bags for fast food items

- Microwave popcorn bags and pizza box liners

- Paper cups and soup containers requiring water and oil repellency

Why PFAS-Free Packaging is a Critical Buyer Issue

The shift to PFAS Free Food Packaging is accelerating, transforming from a voluntary sustainability trend into an essential requirement for market entry and brand integrity. For professional buyers, procurement specialists, and restaurant chain operators, 2025 marks a pivotal moment where continued success depends entirely on navigating this transition correctly. Failure to adapt poses significant financial and reputational risks.

The Health and Environmental Threat of “Forever Chemicals”

The severity of the “forever chemical” threat has forced governments and consumers to act decisively. Buyers today are responding to clear scientific consensus that legacy packaging containing PFAS is unsustainable and unsafe. Every purchase decision involving non PFAS Free Food Packaging carries a long term liability. This liability extends beyond simply meeting a ban; it involves taking responsibility for products that contribute to contamination.

The primary concerns driving this market change are focused on:

- Migration Risk: PFAS can leach out of packaging materials and directly into the food they contain, especially when exposed to heat or grease. This is the direct pathway of human exposure that food service companies must eliminate.

- Contamination of Compost: Even compostable products that contain PFAS contaminate the resulting nutrient rich compost, preventing its safe use in agriculture and thereby closing a critical loop in the circular economy. Buyers must ensure their packaging supports a clean composting stream.

- Public Scrutiny: Major retailers and media outlets frequently highlight brands that fail to adopt safer alternatives, leading to damaging public relations crises.

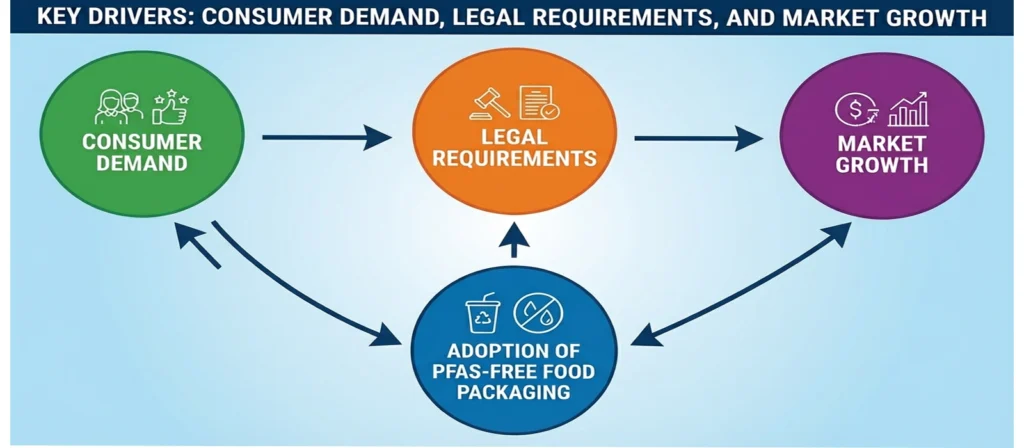

Key Drivers: Consumer Demand, Legal Requirements, and Market Growth

The necessity of adopting PFAS Free Food Packaging is propelled by three powerful, interconnected market forces.

1. Legal Requirements and Regulatory Deadlines

Across the globe, legislative bodies are implementing outright bans on the intentional use of PFAS in food contact materials. For buyers, the regulatory landscape is shifting from a patchwork of state laws to broader, more encompassing federal and regional mandates.

The implication is that inventory sourced today must meet the standards of tomorrow. Holding onto stock of non PFAS Free Food Packaging can lead to:

- Mandatory product recalls and associated disposal costs.

- Significant fines and legal penalties for noncompliance.

- Loss of market access in regions with strict new rules.

2. Growing Consumer Demand for Non-Toxic Products

Today’s consumers are highly educated about chemical safety. The rise of social media and accessible scientific reporting means that the term PFAS is widely recognized as a chemical to avoid. Customers are actively seeking out non toxic, safe alternatives.

For quick service restaurants QSRs and retailers, providing transparently PFAS Free Food Packaging is a powerful marketing tool. It signals brand commitment to health and sustainability, moving it from a cost center to a value added feature. Brands that proactively communicate their use of safe packaging gain a substantial competitive edge.

3. Exponential Market Growth

The market for sustainable and PFAS Free Food Packaging alternatives is experiencing rapid double digit growth. This trend signals to buyers that reliance on traditional, non-compliant packaging is a shrinking market with diminishing returns. By committing to PFAS free alternatives, buyers align their sourcing strategy with future market profitability and ensure supply chain stability in the long run. The smart investment is in the compliant, growth oriented segment of the market.

PFAS-Free Materials and Product Options

The industry’s transition has spurred major innovation in material science, resulting in numerous commercially viable and high performing alternatives for PFAS Free Food Packaging. Buyers now have a wide range of options to meet their diverse needs for hot, cold, wet, or greasy foods without compromising safety or environmental responsibility. Choosing the right material depends on the specific food application, required heat resistance, and local composting infrastructure.

1. Sugarcane Bagasse The Compostable Fiber Alternative

Bagasse, a byproduct of sugarcane processing, has become one of the leading choices for molded fiber PFAS Free Food Packaging. It is an annually renewable resource and performs exceptionally well across various food service applications. Unlike paper products that traditionally rely on PFAS for grease resistance, bagasse inherently possesses strong fiber structure that can be treated with plant based coatings.

Key Features of Bagasse Products:

- Heat Stability: Bagasse performs well in high heat environments, making it suitable for hot meals, microwave reheating, and oven safe applications up to certain temperatures.

- Compostability: The material is naturally compostable, breaking down rapidly in industrial composting facilities, supporting a circular economy model.

- Sturdy Structure: It forms strong, rigid products like clamshells, plates, and bowls, offering better structural integrity than some lightweight paper options.

2.PLA Polylactic Acid Clear Solutions for Cold Applications

PLA is a bioplastic made from renewable resources such as corn starch or sugarcane. After processing, it becomes a clear and versatile polymer used as a liner for paper cups and bowls or molded into containers, lids and cutlery. It offers reliable moisture resistance for many food applications and is naturally free of PFAS, making it a safe choice for sustainable packaging.

PLA is an excellent alternative for:

- Clear deli containers and salad bowls, offering high visibility for merchandising.

- Cold drink cups, as it maintains its structure well when chilled.

- Lining hot cups and bowls where grease and moisture barrier is needed, replacing traditional plastic PE linings.

It is important to note that standard PLA is primarily suitable for cold applications or containers that do not exceed $105^\circ \text{F}$. However, modified crystalline PLA CPLA offers enhanced heat resistance suitable for cutlery and some hot food lids.

3. Kraft Paper and Water-Based Coatings The Flexible Option

Kraft paper is widely used for bags, wraps, and food box liners due to its strength and flexibility. To qualify as PFAS Free Food Packaging, Kraft paper requires a specific barrier coating to achieve necessary grease and moisture resistance without fluorochemicals.Manufacturers now rely on advanced water based coatings made from natural polymers or clay dispersions. These coatings are essential because they create an effective, non toxic barrier against oil and moisture, directly replacing the function of PFAS.

When sourcing Kraft paper products, buyers must verify:

- The finished product maintains its integrity when used as flexible packaging for items like fries, pastries, or sandwiches.

- The coating is explicitly certified as PFAS free.

- The barrier provides sufficient grease resistance for the intended application, often validated via the Kit Test.

Product Categories Clamshells, Bowls, Cups, and Cutlery

The availability of PFAS Free Food Packaging now covers nearly the entire range of disposable food service items. Buyers can transition their entire inventory to safe alternatives, maintaining consistency across their brand’s offerings.

- Clamshell Containers: Primarily made from bagasse or fiber treated with water based coatings, designed for hot sandwiches, burgers, and entrees.

- Bowls and Soup Containers: Available in bagasse or paperboard lined with PLA or water based barriers, suitable for both hot soups and cold salads.

- Cups: Cold cups use standard PLA or a PLA liner; hot cups use PLA or water based coatings, sometimes featuring a double wall for insulation.

- Cutlery: Often made from CPLA high heat PLA or wood/bamboo, providing sturdy, compostable eating utensils.

This comprehensive material shift ensures that the functional requirements of food service packaging are met while satisfying the fundamental compliance and safety requirement of being free from PFAS.

Global Regulations and Market Trends The Rise of PFAS-Free

The regulatory environment is the single biggest forcing function driving the adoption of PFAS Free Food Packaging. As global restrictions tighten, compliance is non negotiable for any enterprise operating internationally or planning future expansion. Market trends reflect a race toward preemptive compliance and the establishment of new global standards for safe food contact materials. The table below details the key regulations and quantitative standards shaping the PFAS Free Food Packaging market.

| Region | Regulatory Focus | Key Standards and Thresholds | Impact on PFAS Free Food Packaging |

| European Union (EU) | Precautionary Principle & REACH | REACH Regulation: Near total restriction of PFAS in food contact materials. | Requires robust supply chain transparency and verifiable PFAS Free Food Packaging status for all imports. |

| EN 13432: Mandatory compostability standard. Total Fluorine Testing: Third party certification schemes often demand less than $100$ ppm total organic fluorine. | Distributors must secure dual certification for fiber products to confirm safety and end of life compliance. | ||

| United States (US) | State-Driven Bans (Patchwork Model) | California AB 1200: Bans PFAS in plant fiber based food packaging effective January 2023. | Forces buyers to adopt national PFAS Free Food Packaging standards to simplify logistics and ensure market access in key states. |

| Washington, New York, Maine: Similar state level prohibitions based on non detect or low parts per billion ppb total fluorine limits. | Buyers must track multiple state deadlines; the safest strategy is meeting the strictest state law available. | ||

| Canada | Federal Prohibition | Health Canada: Federal directives prohibiting the use of PFAS in food contact materials and requiring specific import documentation. | Strict border controls mandate that all imported PFAS Free Food Packaging is accompanied by verifiable compliance documentation. |

| Asia Pacific (APAC) | Evolving Eco-Labeling and Trade Demand | Certifications: Driven by multinational QSR demands and eco labeling requirements in markets like South Korea and Japan. | Suppliers in the region are forced to meet EU or US PFAS Free Food Packaging standards to remain competitive in global supply chains. |

The move toward PFAS Free Food Packaging is no longer a niche choice but an unavoidable mandate. By standardizing procurement around the strictest global regulations and demanding certified testing data, buyers ensure market stability and secure their brand’s reputation for safety and sustainability.

Buyer Mistakes to Avoid in PFAS-Free Packaging Procurement

The shift to PFAS Free Food Packaging is fraught with potential pitfalls. Due to misleading labeling, complex material science, and varying supplier honesty, buyers frequently make errors that result in costly noncompliance, material failure, and reputational harm. Recognizing these common mistakes is crucial for successful sourcing.

Mistake 1: Confusing “Compostable” with “PFAS-Free”

This is arguably the most common and costly error. Many molded fiber products were labeled compostable while still relying on PFAS for grease resistance. Assuming an eco-friendly label guarantees safety is a dangerous practice that contaminates compost and leads to noncompliant inventory. Buyers must specifically require evidence of PFAS free status alongside compostability certification to ensure true safety and circularity.

Mistake 2: Ignoring Third-Party Certification

Relying solely on a supplier’s internal claims or self issued documentation is a critical lapse in due diligence. The complexity of testing for trace amounts of PFAS demands specialized laboratory equipment and validated methods. The only reliable proof that packaging is truly PFAS Free Food Packaging comes from independent, accredited third party testing and detailed compliance reports, which serve as legal indemnity for buyers.

Mistake 3: Overlooking Material Composition and Coatings

The devil is often in the details of the material coating. A product may claim to be plant based, but the water repellent barrier may contain trace PFAS if the manufacturer has not fully cleaned their production lines. Understanding the exact chemical composition of the grease resistant treatment prevents regrettable substitution and ensures the best PFAS Free Food Packaging uses known safe alternatives like PLA or certified water based barriers.

Mistake 4: Not Verifying Heat and Grease Resistance Performance

PFAS were used because they worked exceptionally well, and achieving comparable performance is the primary challenge for new alternatives. Buyers often assume the new material performs like the old, only to discover leaks or structural failure with hot or oily foods. Before large scale purchases, buyers must conduct rigorous in house testing and request technical data sheets to verify temperature thresholds

Key Mistake Summary:

- Assuming “compostable” means PFAS free

- Skipping vital third party certification reports

- Overlooking the exact chemical composition of coatings

- Failing to test heat and grease resistance internally

Failure to perform these application specific tests can lead to inventory that performs poorly, resulting in unhappy customers and wasted product.

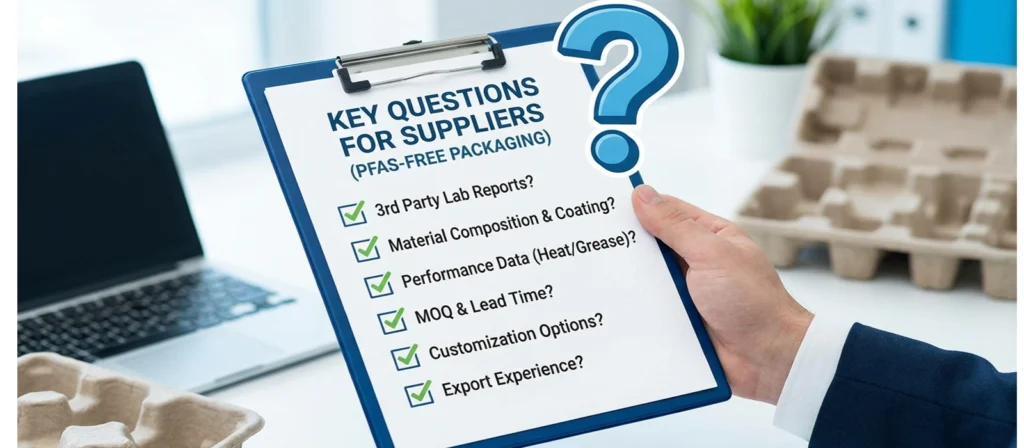

Moving to PFAS Free Food Packaging requires a fundamental shift in how buyers engage with their suppliers. The procurement conversation must evolve from price and volume to encompass stringent compliance and transparency. Asking the right questions is the only way to safeguard your supply chain and brand reputation.

Key Questions Buyers Must Ask Suppliers

Question 1: Certification and Testing Verification

Buyers must demand current third party lab reports confirming the absence of intentionally added PFAS and trace analysis. Verify global compostability certifications like BPI or Seedling, ensuring the PFAS Free Food Packaging meets both chemical safety and end of life compliance, and confirm the supplier’s internal Quality Control protocol for cross contamination prevention.

Question 2: Material Composition and Coating Type

To ensure a true PFAS Free Food Packaging solution, investigate the exact base material and the specific composition of the moisture and grease barrier, looking for explicit confirmation of PLA, CPLA, or certified water based coatings. Clarify whether the material is recyclable, compostable, or both, and verify that all raw material suppliers provide PFAS free declarations.

Question 3: Performance Guarantees (Grease/Oil and Heat Resistance)

The new PFAS Free Food Packaging must perform reliably, so buyers need to quantify the capability by asking for the maximum continuous temperature the product can handle, including suitability for reheating. Require the certified Kit Test rating or OGR score, and ask if enhanced barrier options are available for extremely oily or saucy foods.

Question 4: Logistics and Fulfillment (MOQ & Lead Time)

To plan inventory effectively, determine the Minimum Order Quantity MOQ and the average production lead time for a standard order. Confirm if shipments are optimized for international container space and if the supplier maintains buffer stock for key PFAS Free Food Packaging items to mitigate unexpected supply chain delays.

Question 5: Customization and Branding Options

Buyers must inquire about custom printing and color matching capabilities, ensuring that all inks used are certified as food grade and PFAS free. Confirm the ability to customize the PFAS Free Food Packaging to display specific sustainability certifications and clarify the associated plate costs and lead time for customized runs.

Question 6: Compliance and Export Experience

Partnering with an experienced supplier is essential for smooth global operations. Buyers must ask for a demonstrable history exporting certified PFAS Free Food Packaging to major markets like the EU and the US. Finally, confirm the supplier’s process for monitoring changes in global PFAS regulations and their ability to assist in providing necessary customs documentation.

Key Questions Summary:

- Requesting third party lab and compostability certifications

- Verifying exact barrier and coating chemical composition

- Quantifying heat and grease resistance performance data

- Clarifying minimum order quantities and production lead times

- Checking if custom printing and food grade inks are PFAS free

- Confirming expertise in global export and compliance documentation

These detailed questions ensure that buyers receive high performing, fully compliant PFAS Free Food Packaging that supports both their business growth and their commitment to environmental safety.

Conclusion

The move toward PFAS free food packaging represents a critical turning point for public health, environmental protection, and responsible supply chain management. By understanding the risks of PFAS, evaluating safe alternative materials, and verifying third party certifications, buyers gain the clarity needed to source truly compliant products. Businesses that adopt PFAS free solutions now position themselves for regulatory readiness, stronger brand trust, and long term market growth. Choosing safe, tested, and transparent packaging is no longer optional but a defining standard for the future of sustainable food service.