An SOS paper bag, also called a Self-Open Sack paper bag, is a flat-bottomed, self-opening bag that can stand upright on its own and securely hold products. Compared with thin, less durable plastic bags, an SOS paper bag maintains its shape, allowing staff to pack food, groceries, and daily items quickly at the counter. It is widely used in retail and food service as simple, reliable, and eco-friendly packaging.

Beyond the basic shape, an SOS paper bag is designed with daily operations in mind. The flat bottom gives it a box-like volume, while the side gussets allow the bag to open wide and stand steady during filling. Most SOS paper bags are made from kraft paper, with options for food-grade liners and custom printing for branding and product information. This mix of function, hygiene, and flexibility is what makes the SOS paper bag a practical fit for modern packaging needs.

Imagine a bustling lunchtime takeout counter: an employee picks up a stack of SOS paper bags, the opening swiftly unfolds, and boxed meals and snacks slide in easily, the bags remaining securely in place, making it convenient to add sauces and napkins. No need to move containers or struggle with soft plastic bags. This simple scenario demonstrates how SOS paper bags subtly improve efficiency, hygiene, and brand image in real life. In the following sections, we’ll explore the history, definition, sizes, and applications of SOS paper bags across various industries, as well as the factors to consider when choosing the right SOS paper bags for your packaging needs.

Understanding SOS Bag Definition and History

Understanding an SOS bag starts with its structure. An SOS paper bag, or Self-Open Sack, is a pre-glued, side-gusseted paper bag with a rectangular flat bottom that allows it to stand upright without support. When you pick it up and pull it open, the base automatically pops into shape, forming a stable box-like cavity. This self-opening feature means products can be loaded quickly and neatly, whether they are food containers, groceries, or small packaged goods that need to stay upright during handling and transport.

In industry terms, an SOS paper bag is not just any paper carrier but a specific format designed for speed, consistency, and volume packing. It usually comes in standardized sizes, made from kraft or white paper, sometimes with inner linings for food contact or extra strength. The clean surfaces are suitable for printing branding, product information, or handling instructions, which helps businesses present a tidy, professional look.

Origins and Development of the SOS Paper Bag

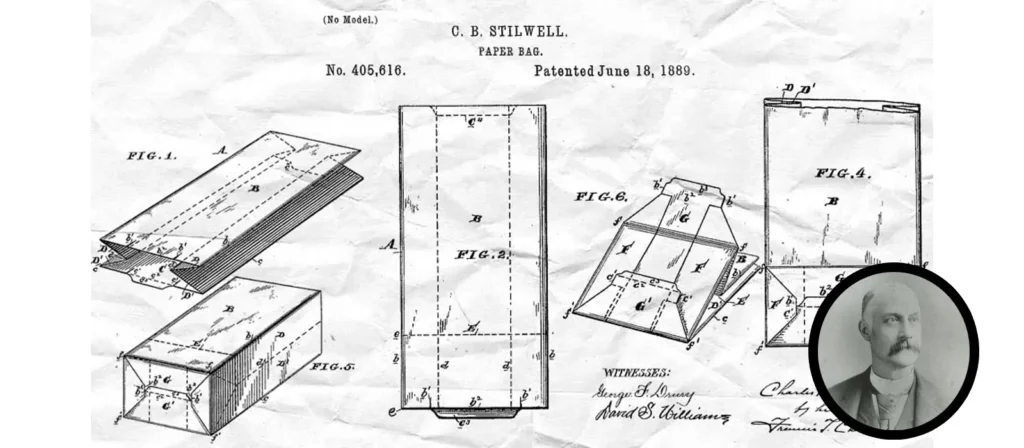

The story of the SOS paper bag began in the late nineteenth century, when retailers needed a better solution than loose wrapping paper and simple flat bags. American inventor Charles Stilwell is widely credited with developing the Self-Opening Sack design and securing patents for a machine that could mass-produce square-bottom bags. His idea was to create a bag that arrived flat for storage, but opened itself into a box-like form with one motion, saving shop assistants precious time while improving how goods were packed and carried home.

As urban retail, bakeries, and later supermarkets grew through the twentieth century, the SOS paper bag format spread quickly. Brands and stores adopted it for bread, dry foods, and everyday goods because it combined machinability with a neat, standing shape on shelves and counters. When environmental awareness and concern about plastic waste increased in the late twentieth and early twenty-first centuries, the existing SOS bag design found new life as an eco-aligned packaging choice. It evolved with food-safe papers, grease-resistant options, and stronger bases, but the core Self-Open Sack concept remained largely unchanged

SOS Paper Bag Sizing

When you talk about SOS paper bag sizing, most suppliers use a simple set of measurements: width, gusset (side fold), and height. These three numbers decide how much volume the bag can hold, whether it can take a burger box and drink, or just a few snacks and small items. While every factory has its own catalogue, most SOS paper bags fall into a few common size ranges that cover takeaway, bakery, grocery, and small retail use.

- Small SOS paper bags

Often used for snacks, small bakery items, or pharmacy products. Typical sizes might be around 120 × 70 × 220 mm or 150 × 80 × 260 mm, giving enough room for light, compact items without wasting material. - Medium SOS paper bags

This is the most common category for food service and convenience retail. A medium SOS paper bag might be 180 × 100 × 280 mm or 200 × 110 × 320 mm, which suits burger boxes, sandwich packs, or a mix of snacks and drinks. - Large SOS paper bags

Designed for family meals, multiple containers, or heavier groceries. Sizes such as 240 × 120 × 360 mm or 260 × 140 × 420 mm are typical, with a wider base to keep several food boxes or bulkier products stable during transport. - Extra large or heavy duty SOS paper bags

Used when you need extra volume or strength, for example large takeaway orders, multiple grocery items, or bulk packaged goods. These bags may exceed 280 mm in width and 450 mm in height, sometimes combined with thicker paper grades to support higher loads. - Custom sized SOS paper bags

Many brands choose custom sizes to match specific containers or shelf layouts. In this case, the bag dimensions are adjusted so that branded boxes, cups, or product bundles fit snugly without tipping or wasted space, helping both handling efficiency and presentation.

Application of SOS bags

In real life, the SOS paper bag shows up in many places long before most people ever learn its name. The same flat bottom, self-opening structure makes it useful at a clothing store checkout, a busy coffee bar, a pharmacy counter, or a farm supply shop. By changing the paper grade, size, and printing, one SOS paper bag design can be adapted to very different product types and handling needs.

Retail

In retail, the SOS paper bag often replaces both plastic carry bags and gift wrap. Picture a lifestyle store where customers buy candles, small homeware, and skincare products. Staff pick up an SOS paper bag, it pops open in one movement, then bottles, jars, and boxes stand neatly inside without falling over. The flat bottom helps keep glass items separated and stable, reducing the chance of breakage on the way home.

Fashion boutiques also like the SOS paper bag format for smaller garments, socks, accessories, or folded T-shirts. With a clean exterior for branding, the bag works as a mobile advertisement once the customer walks out of the store. For supermarkets and convenience shops, smaller SOS paper bags are ideal for impulse buys at the checkout, such as snacks, cosmetics, or seasonal goods. In each of these settings, the self-opening structure reduces packing time and keeps the counter area tidy.

Food and beverage services

Food and beverages are one of the most visible homes of the SOS paper bag. At a quick service restaurant during the lunch rush, staff load burger boxes, fries, and drinks into a medium or large SOS paper bag. The flat base supports the meal boxes in a stacked or side-by-side layout, while sauces, napkins, and cutlery are tucked in around them. Customers can carry several items in one hand without everything tipping over.

Coffee shops and bakeries also rely on this format. A barista might slide a pastry box, a slice of cake in a clamshell, and a pack of coffee beans into a printed SOS paper bag, then fold the top over for easier carrying. The paper surface absorbs minor condensation from warm food better than a plastic option, and the upright structure keeps delicate baked goods from getting crushed. For delivery platforms and takeaway orders, using a branded SOS paper bag helps maintain a neat presentation when the order arrives at the customer’s door.

Pharmaceuticals and healthcare applications

In pharmacies and healthcare settings, the SOS paper bag plays a quieter but important role. When a pharmacist hands over prescription medicines, the items are usually placed in a plain or discreetly branded SOS paper bag. The flat bottom allows medicine bottles, blister packs, and instruction leaflets to sit upright, so labels stay readable and small items are less likely to fall out when the bag is opened at home.

Many pharmacies print dosage reminders, safety warnings, or brand contact details directly onto the SOS paper bag. This turns the packaging into a simple communication tool that reaches the patient every time they pick up their medication. In clinics and small healthcare facilities, SOS paper bags may also be used to pack sample containers, medical supplies, or over-the-counter items. The quick self-opening action reduces handling time, while the paper material aligns better with privacy and professionalism than noisy, transparent plastic.

Agricultural products and bulk goods

For agricultural products and bulk goods, the SOS paper bag is often scaled up and strengthened. Farm shops and seed retailers use larger, heavier paper grades to hold dried seeds, animal feed samples, soil amendments, or garden products. The wide, flat base keeps heavy contents stable on pallets or shelves, and the upright shape makes it easier to pour out the product in controlled amounts.

In some cases, an SOS paper bag may be combined with an inner liner or coated paper to handle dusty or oily materials. Think of a garden center selling bulk bird feed or lawn treatment: staff scoop the product into the open bag, the base supports the weight, and the top is folded or taped down for transport.

Benefits of SOS Bags In The Food Industry

In the food industry, small details in packaging can make or break the whole service experience. The way meals are packed affects speed at the counter, how well food travels, and what the customer feels when they open the bag at home or in the office. The SOS paper bag fits neatly into this daily routine: its flat bottom, quick self-opening action, and reliable structure help kitchens, front-of-house staff, and delivery riders work faster, while still keeping food presentable and safe to handle.

Great for Takeaway

For takeaway shops and quick service restaurants, time and consistency matter more than anything. Staff often have only a few seconds to pack each order, especially during peak hours. An SOS paper bag opens in one simple motion and stays upright on its own, so staff can slide in burger boxes, rice bowls, noodle containers or snack trays without having to hold the bag open with one hand. This reduces fumbling at the counter and keeps the packing line flowing smoothly.

From the customer’s point of view, a takeaway order in an SOS paper bag feels more organised. Boxes sit flat instead of tipping over, sauces and side dishes can be placed neatly in the gaps, and the top can be folded or rolled for extra security. When the customer arrives at their destination and opens the bag, the food is more likely to look close to how it left the kitchen, which supports a better eating experience and fewer complaints about spilled meals.

Suitable for both hot and cold foods

Food businesses rarely serve only one type of product. A single order might include a hot main dish, a cold dessert and a drink. The structure and material of an SOS paper bag handle this mix reasonably well. The paper walls allow some steam to pass through, which helps reduce condensation build-up around hot food containers. At the same time, the bag keeps cold items such as salads, chilled desserts or bottled drinks upright and separated from hotter items, so they do not get crushed or warmed up too quickly.

In practice, this means a restaurant can use one main bag type for a wide range of menu combinations. A hot pizza box and a cold drink can share a large, sturdy bag, while a medium bag can hold a warm sandwich and a cold side salad. The flat bottom and side gussets create enough space for containers to sit side by side rather than stacked in a way that causes pressure or leakage. For kitchens and franchise operations, this versatility simplifies packaging choices and reduces the number of different bag formats they need to keep in stock.

Food Safe Packaging

In food packaging, the bag is part of the eating experience, not just a way to carry things home. An SOS paper bag made from food-grade kraft paper gives takeaways, bakeries, and quick service restaurants a packaging option that supports both safety and sustainability. The paper surface is suitable for direct food contact in many formats, and when combined with grease-resistant or moisture-resistant grades, it can handle items like burgers, fries, pastries, or hot snacks without falling apart too quickly. Compared with many plastic options, a plain kraft SOS paper bag is easier for customers to accept as a “better” choice when they finish their meal and need to dispose of the packaging.

For food service brands, the outside of the bag becomes a simple tool to communicate how the packaging should be handled after use. Messages such as “recyclable where facilities exist”, “paper from responsibly managed sources,” or clear icons about separating food waste and packaging can be printed directly on the bag. Even when heavy grease or sauce stains mean the bag cannot be recycled in every region, customers still tend to view a paper-based SOS paper bag as more in line with modern food packaging standards, where reducing plastic use and choosing fibre-based materials is an important step. In busy takeaway and delivery operations, this kind of everyday eco choice helps align the packaging with the expectations of diners who care about how their food is packed.

Cost-effective

Food businesses use packaging in large, constant volumes, so small differences in unit price and performance quickly show up in the monthly costs. An SOS paper bag is often chosen because it offers a practical balance between strength and price for takeaway and delivery operations. The bags are produced on high-speed paper bag machines, using standard food-grade kraft, which helps keep per-unit costs predictable even when there is custom printing for the restaurant logo or menu messages. Since they are delivered flat and stacked tightly, they take up less storage space in the kitchen or behind the counter, leaving more room for ingredients and equipment.

In daily service, the way an SOS paper bag behaves also has a cost impact. When the Self-Open Sack structure pops into shape with one movement, staff can pack hot meals, sides, and drinks faster, which is critical during peak times. A correctly sized, sturdy bag reduces the chance of containers tipping, sauces leaking, or meals being damaged on the way to the customer, whether they pick up at the counter or receive a delivery rider at their door. Fewer damaged orders mean fewer replacements and less wasted food. The reduced need for double bagging or “extra” plastic carriers also cuts consumption of other packaging materials. Over a long period, these operational details make the SOS paper bag a cost-effective choice specifically for food packaging, not only at the moment of purchase but across the full service process.

Environmental Features of SOS Paper Bags

Renewable and Responsibly Sourced Materials

At the most basic level, an SOS paper bag starts with fibre, usually from wood pulp. When that pulp comes from responsibly managed forests or recycled sources, the packaging has a clearer environmental story than many fossil fuel based plastics. For brands, this means they can choose SOS paper bags made with certified or documented paper grades and show that their packaging is tied to renewable raw materials rather than purely petrochemical inputs.

Recyclability and End-of-Life Disposal Options

A key environmental feature of SOS paper bags is their compatibility with many existing paper recycling processes, provided they are clean enough and the local recycling facilities accept the material.

In the food service industry, the actual recycling situation is somewhat complicated, as grease, sauces, and large amounts of food scraps limit recycling options. Even so, SOS paper bags that end up in general waste are generally easier to decompose than many similar plastic bags. In some areas, partially soiled paper packaging may be suitable for composting or industrial processing with food waste. While regulations vary by location, the core principle is that fiber-based packaging bags have more potential end-of-life disposal pathways than many single-use plastic bags, supporting a more circular packaging philosophy.

Reduced Reliance on Single-Use Plastics

Every time a restaurant, café, or store switches from a plastic carrier to an SOS paper bag, it reduces its direct use of single-use plastic items. On its own, one bag is a small change, but across thousands of orders per week, the impact becomes meaningful. Many countries and cities now have restrictions, fees, or social pressure around plastic bags for food and retail. Choosing a sturdy SOS paper bag helps businesses stay ahead of these trends and avoid relying on plastic as the default solution.

Alignment with Modern Environmental Standards

From a marketing perspective, the environmental features of SOS paper bags can be integrated into broader sustainability reporting. Details such as the share of recycled content, the use of certified paper, or the reduction of plastic carriers can be counted and reported over time. This gives businesses concrete numbers to talk about, rather than vague promises. When a company chooses the SOS paper bag as part of its packaging mix, it is stepping into a format that can be aligned with environmental standards in a clear, measurable way, which is increasingly important for both regulators and customers.

Factors to consider when purchasing SOS bags

Bag Size and Capacity Planning

The first decision is always size. Before choosing any SOS paper bag, think about the exact products it needs to carry: portion sizes, container shapes, and whether items are stacked or placed side by side. A bag that is too small will strain at the seams and risk tearing, while one that is too large can let containers slide around, causing spills and poor presentation. Mapping your main products to specific bag sizes is a simple exercise, but it makes a big difference to service quality.

Paper Grade and Strength

The paper itself is the backbone of every SOS paper bag. Different GSM (grams per square metre) levels and paper types provide different levels of strength, tear resistance, and stiffness. For light food items such as pastries or small snacks, a standard Kraft paper may be enough. For heavier takeaway boxes, large drink combinations, or bulk goods, a thicker or multi-ply paper grade is usually safer. Choosing the correct paper grade reduces the risk of handles tearing, bottoms giving way, or sides splitting under load.

Food Contact Safety and Compliance

If the SOS paper bag is used directly with food, rather than only holding sealed containers, food contact safety becomes a primary concern. For items like bakery goods, sandwiches in wraps or snacks placed directly in the bag, you need grades that are certified for food contact and ideally supported by documentation for the markets where you operate. Grease-resistant or moisture-resistant papers may be required for oily or hot products, to keep the bag from weakening too quickly.

Printing, Branding and Surface Finish

For many businesses, the SOS paper bag is not just a carrier but a moving piece of advertising. The available printing methods, number of colours and surface finish have a direct impact on how your brand appears in the street, in offices and in customers’ social media photos. Simple one- or two-colour logos may be enough for a minimal look, while more complex artwork might require higher-end printing and tighter control over colour consistency.

The surface of the bag also matters. Uncoated kraft provides a natural, rustic feel that suits eco-focused cafés and bakeries, while white or coated papers can give a cleaner, more premium look for cosmetic or pharmacy uses. When choosing a supplier, ask for printed samples so you can judge how sharp the artwork appears, how well colours are reproduced, and how the surface reacts to handling and light grease. Good print quality on an SOS paper bag quietly supports the overall brand experience.

Supplier Reliability, MOQs, and Lead Time

Even the best-designed SOS paper bag is only useful if it arrives on time and in the right quantity. When choosing a supplier, take a close look at minimum order quantities (MOQs), standard lead times, and their flexibility during busy seasons. A partner that can handle both regular orders and occasional rush jobs is valuable for businesses with strong seasonal peaks or frequent promotions.

It is also wise to ask how quality control is managed. Consistent bag dimensions, paper strength, and print alignment are crucial when you run standardised operations across several outlets or regions. Checking references, visiting production facilities if possible, or starting with a trial order can help assess whether the supplier is a good long-term fit. For brands that operate internationally, understanding how the supplier handles export documentation and logistics is another important part of the decision.

Conclusion

In summary, SOS paper bags are more than just simple flat-bottomed bags. They are a form of packaging that silently supports the entire process of modern business, from busy takeout counters and small neighborhood bakeries to pharmacies and agricultural supply stores. Their self-opening structure, stable bottom, and accordion side pleats allow for quick packaging and safe transport, while the paper material aligns with current expectations for environmentally friendly packaging.

If you are evaluating your current packaging, the next practical step is to match your main products and order types with specific SOS paper bag sizes and specifications. Test actual orders with sample bags to assess their performance in daily use and check that their compliance and environmental claims are documented. Through this structured approach, SOS paper bags will become a reliable, flexible, and future-proof component of your packaging system, not just another item on your purchasing list.