Choosing sustainable cutlery may seem like a simple decision, but when you are faced with terms like PLA and CPLA, the choice becomes surprisingly complex. Both are promoted as eco-friendly, compostable, and plant based, yet they perform differently, break down under different conditions, and serve different roles in food service.

In this guide, we provide a detailed comparison of PLA vs CPLA cutlery. You will learn how each is made, how they perform in real-world use, and how they fit into sustainable food systems. Whether you are managing a business, planning an event, or looking to reduce waste responsibly, this article will help you make an informed and practical decision.

What is PLA?

PLA, or Polylactic Acid, is a bioplastic derived from renewable plant sources like corn starch, sugarcane, or cassava. Unlike petroleum-based plastics, PLA is classified as a biodegradable thermoplastic, meaning it can break down under the right industrial composting conditions. This makes it a popular choice for single-use products like cups, food containers, and cutlery.

Despite being called a “plastic,” PLA doesn’t come from fossil fuels. Instead, it is synthesized through the fermentation of plant sugars, making it a more sustainable option compared to conventional plastic utensils.

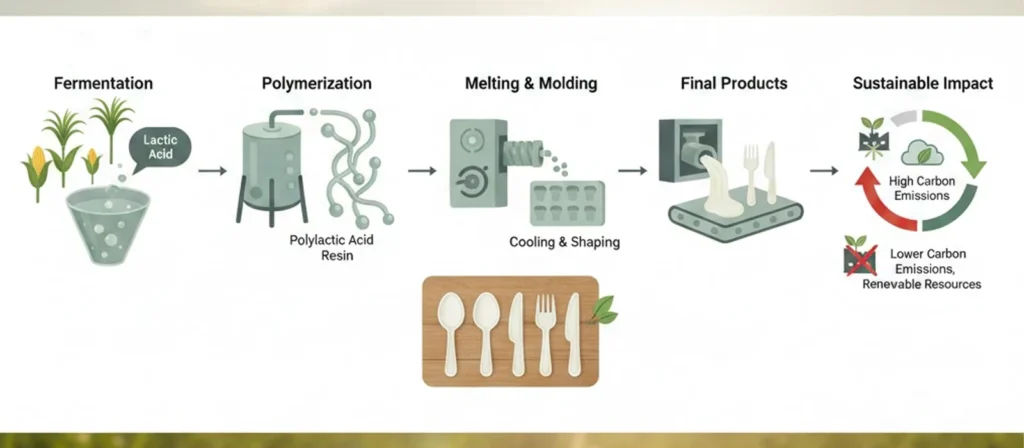

How PLA is Made

The production of PLA starts with fermenting natural sugars extracted from plants into lactic acid. This acid is then polymerized into long molecular chains, forming polylactic acid resin. The resin is melted, molded, and cooled into specific shapes such as spoons, forks, and knives using conventional plastic manufacturing equipment.

The process results in fewer carbon emissions than fossil-based plastic production and relies on renewable agricultural inputs, reducing dependency on oil.

PLA Applications in the Food Industry

As the demand for sustainable packaging grows, PLA has become a popular material in the food industry for cold and lightweight applications. It is derived from renewable resources and offers a compostable alternative to petroleum-based plastics, making it attractive to businesses aiming to reduce their environmental footprint. PLA performs well in food service settings where high heat is not a concern, and it supports clean branding and clear presentation.

Common food-related products made from PLA include:

- Cold beverage cups used for iced coffee, smoothies, and juices

- Cup lids for takeout drinks, including dome and flat lid styles

- Salad containers such as clamshell boxes for fresh meals

- Takeout bowls and trays for room-temperature food items

- Cutlery sets including forks, spoons, and knives for cold meals

- Food wrap films as compostable alternatives to plastic wrap

- Portion cups and lids used for sauces, dressings, or dips

- Bakery containers that hold cakes, pastries, and cookies

- Straws designed for cold beverages

- Blister packaging used for snacks or ready-to-eat items

These applications are especially common in cafes, quick-serve restaurants, eco-conscious food brands, and delivery platforms focused on sustainable packaging.

What is CPLA?

CPLA stands for Crystallized Polylactic Acid. It is essentially PLA that has undergone a crystallization process to enhance its structural and thermal properties. While it is made from the same plant-based materials as PLA, CPLA is designed to withstand higher temperatures and offer greater durability.

This makes CPLA a better choice for hot foods and demanding use cases where regular PLA might soften or deform. In appearance and texture, CPLA cutlery is often more rigid, with a matte finish rather than the glossy look of PLA.

CPLA is still compostable in industrial facilities, but it is not suitable for home composting, just like PLA.

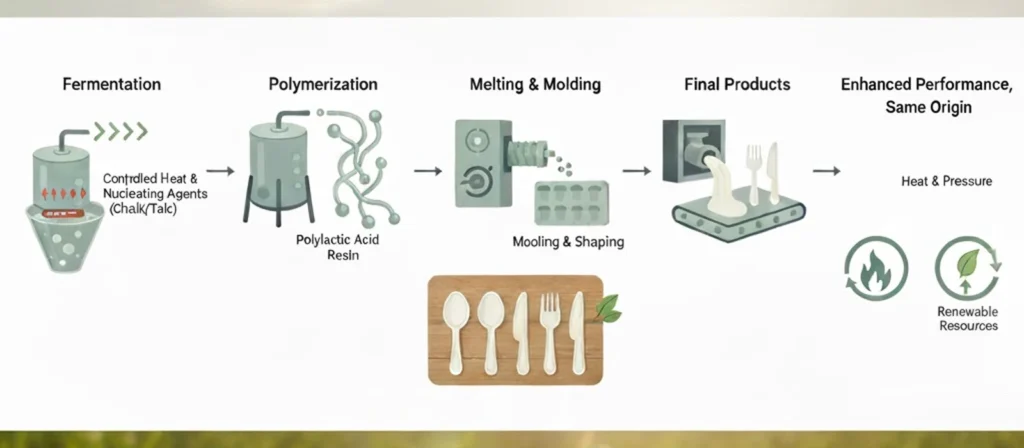

How CPLA is Made

The process of creating CPLA begins with regular PLA. Through controlled heat and the addition of chalk or talc-based nucleating agents, the molecular structure of PLA is altered. This induces crystallization, giving the final material its signature strength and heat resistance.

This structural transformation does not change its origin — it is still made from renewable resources — but it significantly improves performance, especially under heat or pressure.

CPLA Applications in the Food Industry

CPLA is a modified form of PLA with enhanced heat resistance and structural strength, making it ideal for food packaging that needs to perform under higher temperatures. Its durability and compostability in industrial settings allow food businesses to offer more sustainable utensils and containers without compromising functionality. CPLA is often preferred in hot food environments where standard PLA would deform.

Typical food-related products made from CPLA include:

- Hot food cutlery including forks, knives, and spoons used in restaurants and catering

- Utensil kits pre-packed with napkins and compostable CPLA cutlery for takeout

- Heat-resistant lids for soup cups, noodle bowls, or hot drink containers

- Sturdy takeout boxes designed to hold warm meals and prevent leakage

- Microwave-safe food trays for meal prep services or ready-to-eat items

- Compostable steak knives or serving tools for events and food trucks

- CPLA coffee stirrers for hot beverages served in cafes

- High-end catering utensils used in formal or premium dining events

- Institutional foodservice tools for hospitals, schools, or cafeterias

CPLA is especially valuable in sectors that require reliable performance under heat, such as full-service restaurants, corporate catering, airline meals, and hospitality events. It combines sustainability goals with the practical needs of professional food handling.

PLA vs CPLA: Physical & Chemical Properties Comparison

| Property | PLA | CPLA |

|---|---|---|

| Molecular Formula | (C3H4O2)n | Based on PLA with additives |

| Density | 1.21–1.43 g/cm³ | Similar, with added fillers |

| Melting Point | 155–185°C | Not specified, crystallized version |

| Glass Transition Temp | 60–65°C | Slightly higher due to structure |

| Heat Resistance | Up to 55–60°C | Up to 80–100°C |

| Tensile Strength | 40–60 MPa | Higher than PLA |

| Flexural Modulus | 100–150 MPa | Higher than PLA |

| Elongation at Break | 4–10% | Lower flexibility |

| Impact Strength | 20–300 J/m | More stable under heat and stress |

| Industrial Compostability | Yes (2–4 months) | Yes (2–4 months) |

PLA vs CPLA Cutlery in Real-World Use: Performance, Strength, and Cost

Heat Resistance

One of the most critical differences between PLA and CPLA cutlery is how they respond to heat. PLA begins to soften at temperatures around 55 to 60°C, making it unsuitable for hot soups, entrees, or beverages. It can warp or bend when exposed to steam or high heat, leading to an unpleasant user experience.

CPLA is engineered to solve this problem. Thanks to its crystallized molecular structure, it can withstand temperatures of up to 90 to 100°C without deforming. This makes CPLA cutlery ideal for hot meals, microwave-safe applications, and full-service food operations where heat exposure is routine.

Strength and Durability

PLA cutlery performs adequately for light-use cases but may snap or bend under pressure, especially when used to cut tougher foods like meat or dense vegetables.

CPLA is noticeably stronger and more rigid. It holds its shape under stress and mimics the firmness of conventional plastic. For businesses and events that demand reliability and customer satisfaction, CPLA’s superior strength can justify its slightly higher price.

User Experience

From the customer’s perspective, CPLA feels sturdier and more premium in the hand. Its matte texture and rigidity give it the tactile qualities of high-quality plastic utensils, while PLA’s glossy, lighter feel may come across as flimsy in comparison.

For casual takeout meals or snacks, PLA can be perfectly acceptable. But for formal dining, catered events, or dishes that require active cutting, CPLA enhances both usability and brand perception.

Cost Comparison

PLA cutlery is generally more affordable than CPLA due to its simpler production process. This makes PLA a budget-friendly choice for high-volume, short-duration uses such as festivals, cafeterias, or fast-food chains.

CPLA cutlery is typically 10–20% more expensive, reflecting the added processing required to crystallize the material and improve its properties. However, when weighed against its superior performance, reduced waste from breakage, and better user feedback, many food service operators find the cost increase worthwhile.

PLA vs CPLA Cutlery: Quick Comparison

| Feature | PLA Cutlery | CPLA Cutlery |

|---|---|---|

| Heat Resistance | Softens at 55–60°C Not suitable for hot foods | Withstands up to 90–100°C Ideal for hot meals |

| Strength & Durability | Moderate strength May bend or snap under pressure | High rigidity Performs like traditional plastic |

| Texture & Finish | Glossy and lightweight feel | Matte finish with sturdy grip |

| Best Use Cases | Cold dishes, salads, snacks, takeout | Hot entrees, soups, catering, full-service dining |

| Cost | More affordable Lower production complexity | 10–20% more expensive Crystallization adds cost |

| Compostability | Industrial composting only | Also requires industrial composting |

| User Perception | May feel flimsy to some users | Feels premium and reliable |

The Role of PLA & CPLA in Sustainable Dining

Both PLA and CPLA cutlery have emerged as leading alternatives to traditional plastic utensils in the movement toward more sustainable food service. As consumer awareness around plastic pollution grows, restaurants, cafes, caterers, and event organizers are increasingly turning to bioplastics as a way to reduce their environmental impact while maintaining functionality.

PLA cutlery is often chosen for settings that serve cold or room-temperature foods, such as salad bars, takeout containers, and eco-conscious cafes. Its lightweight feel and visual appeal make it a strong candidate for casual or single-use events where high durability is not essential.

CPLA cutlery, on the other hand, shines in high-heat or full-service environments, such as hot buffets, airline catering, school cafeterias, and formal events where both performance and presentation matter. Its strength and heat tolerance ensure a safe and reliable dining experience even under pressure.

In both cases, these materials can help reduce the carbon footprint of food operations—if paired with industrial composting infrastructure.

Environmental Impact of PLA and CPLA Cutlery

When comparing PLA and CPLA cutlery with traditional petroleum‑based plastic utensils, environmental performance is usually evaluated through life cycle assessment (LCA), which considers raw material sourcing, production emissions, use, and end‑of‑life outcomes.

Lower Carbon Footprint Compared with Conventional Plastics

Studies show that materials like PLA, which are derived from renewable plant sources, often have substantially lower greenhouse gas emissions than fossil‑based plastics.

For example, newly released LCA data indicate that virgin PLA can have an 85 % lower carbon footprint than conventional plastics when measured on a cradle‑to‑gate basis, with values as low as 0.29 kg CO₂‑eq per kg of PLA when biogenic carbon is included. This reduction results from CO₂ uptake during plant growth, offsetting part of the emissions from processing.

Independent research also highlights that switching to compostable bioplastics can offer 7.6 % to 73.75 % lower carbon emissions compared with traditional plastics under favorable life cycle scenarios.

These reductions suggest that PLA and, by extension, CPLA made from the same feedstocks, have significantly lower climate impact during production than polypropylene (PP) or polystyrene (PS) utensils.

Renewable Feedstocks Reduce Fossil Resource Dependence

Both PLA and CPLA are produced from biomass such as corn starch or sugarcane instead of petroleum. Growing crops for PLA/CPLA feedstock absorbs CO₂ as plants photosynthesize, providing what is called a biogenic carbon credit. During growth, the crops sequester CO₂ from the atmosphere, which offsets emissions from later stages of production and disposal.

This renewability sharply contrasts with fossil‑based plastics, for which all carbon emissions are added directly to the atmosphere from extraction through manufacturing.

End‑of‑Life Impact Depends on Composting Infrastructure

The environmental benefit of PLA or CPLA hinges on how the cutlery is disposed:

- Industrial Composting: When cutlery is processed in certified industrial composting facilities, it can fully break down into water, CO₂, and biomass in a matter of weeks, reducing solid waste and returning nutrients to soil. This closes the carbon loop more effectively than landfilling.

- Landfill or General Waste: If PLA or CPLA cutlery ends up in landfill or regular trash, it does not break down efficiently. PLA in landfill conditions can remain largely intact for decades, exhibiting degradation patterns similar to conventional plastics.

Thus, the overall reduction in environmental impact depends on whether local waste systems support industrial composting of bioplastics.

Final Verdict: What Really Matters in Choosing Cutlery?

PLA and CPLA cutlery are not just materials — they are signals of what kind of food experience you are offering and how seriously you take sustainability.

If you serve cold foods, want a clean design, and operate in a system with industrial composting access, PLA does the job without excess. But if you serve hot meals, prioritize utensil performance, or manage brand reputation in the eyes of eco-conscious customers, CPLA offers functional confidence with lower environmental cost than traditional plastics.

At Million Pack, we help businesses of all sizes choose the right sustainable cutlery solution. Our products are tailored to match your menu, your budget, and your environmental goals.