Pressure Sensitive Labels are one of the most widely used label formats in modern packaging because they apply with simple pressure and do not require heat water or solvent activation. For packaging teams they offer a practical way to combine branding compliance and traceability on the same surface while keeping application fast and consistent across different pack sizes and production lines.

In a food packaging context Pressure Sensitive Labels do more than carry a logo. They can communicate ingredients allergens nutrition panels storage guidance and lot codes in a format that is easy for consumers to read and easy for packers to apply at scale. When the label and adhesive are matched correctly to the container and the environment the result is a clean professional finish that stays in place through cold chain handling condensation freezer storage or light oil contact depending on the product.

This guide explains what Pressure Sensitive Labels are how they are made which materials matter most for food packaging and how to choose the right combination for your containers workflows and compliance needs. The goal is to help you make confident decisions that balance performance cost and appearance without oversimplifying the technical details that often cause label failures in real use.

What Are Pressure Sensitive Labels

Key Components of Pressure Sensitive Labels

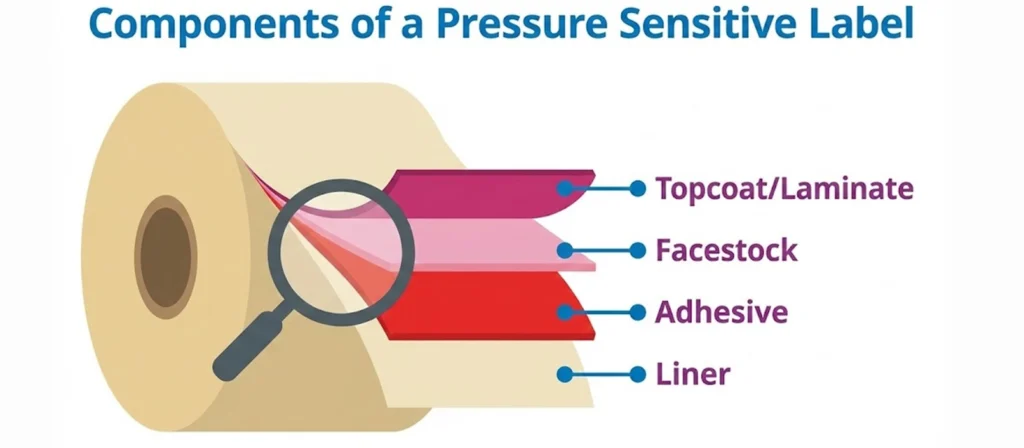

Pressure Sensitive Labels consist of several core components each serving a specific purpose in application performance and durability

- Face material that provides the printable surface and determines appearance texture and stiffness

- Adhesive layer that controls bonding strength tack and resistance to moisture temperature or oils

- Release liner that protects the adhesive before use and supports consistent label dispensing

- Optional surface coating that improves resistance to abrasion moisture or fading during handling

Understanding these components explains why Pressure Sensitive Labels perform reliably across different packaging environments. By adjusting materials and adhesive chemistry manufacturers can optimize label performance without changing the application process.

Definition and Core Characteristics

Pressure Sensitive Labels are self adhesive labels that bond to a surface through light pressure alone without the use of heat water or solvent activation. They come with a pre coated adhesive layer that allows the label to stick immediately once applied to a container or package.

From a structural perspective Pressure Sensitive Labels are not a single material but a functional system made of multiple layers. The face material carries printed information such as branding product details and compliance text while the adhesive layer provides the required holding strength. A release liner protects the adhesive before application and ensures smooth dispensing on labeling equipment. Together these elements create a labeling solution that is reliable across different packaging formats.

One of the defining advantages of Pressure Sensitive Labels is their compatibility with modern packaging operations. They can be applied by hand for short runs or by automated machines for high volume production with minimal setup. This flexibility has made them a common choice in food packaging where producers often handle multiple container shapes materials and batch sizes within the same facility.

How Are Pressure Sensitive Labels Made

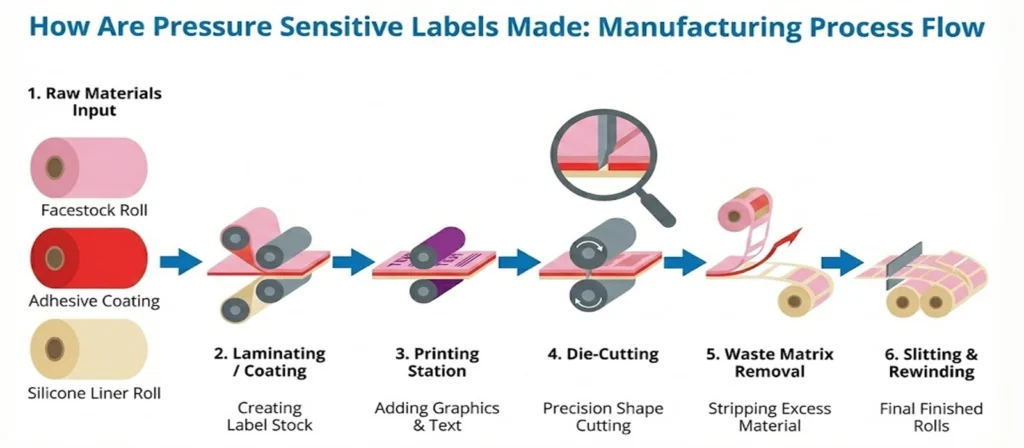

Pressure Sensitive Labels are produced through a standardized manufacturing process that focuses on adhesion reliability print clarity and application consistency. While equipment and materials may differ between suppliers the core steps remain the same across the labeling industry.

- Face material selection

Production starts with choosing a suitable face material such as paper or plastic film based on packaging needs. Materials are supplied in rolls and prepared to ensure stable tension and surface quality before coating. - Adhesive coating

A pressure sensitive adhesive is evenly applied to the back of the face material or to the release liner. Coating weight is carefully controlled because it directly affects initial tack and long term adhesion. - Drying or setting

The coated adhesive passes through controlled heating or cooling to remove carriers and achieve the required bonding properties. This step ensures the adhesive responds properly to pressure during application. - Lamination with release liner

The adhesive layer is combined with a silicone coated release liner. This protects the adhesive and allows smooth label dispensing during application. - Printing

The label stock is printed using flexographic digital or offset methods depending on order volume and design detail. Food safe inks are used to meet packaging regulations. - Die cutting and finishing

Labels are cut to shape on the liner then inspected rewound and packed for shipment.

This streamlined process allows Pressure Sensitive Labels to be produced efficiently while maintaining the performance required for food packaging environments.

What Materials Are Used in Pressure Sensitive Labels

Pressure Sensitive Labels are made from a combination of functional materials rather than a single substrate. Each layer is selected based on how the package will be filled stored handled and displayed. In food packaging especially material compatibility directly affects adhesion legibility and label lifespan.

1. Face Materials

The face material is the visible surface of Pressure Sensitive Labels and carries all printed information. It influences appearance durability and how the label reacts to moisture friction and temperature.

- Paper face materials

- Coated paper for sharp graphics and dense regulatory text

- Uncoated paper for a natural or matte appearance

- Thermal paper for variable data such as weight dates or batch codes

- Plastic film face materials

- Polypropylene for general food packaging and moisture resistance

- Polyethylene for flexible containers and curved surfaces

- Polyester for high strength tear resistance and dimensional stability

Paper face stocks are often used for dry or ambient products while film face stocks are preferred for refrigerated frozen or takeaway food packaging where moisture and handling stress are common.

2. Pressure Sensitive Adhesives

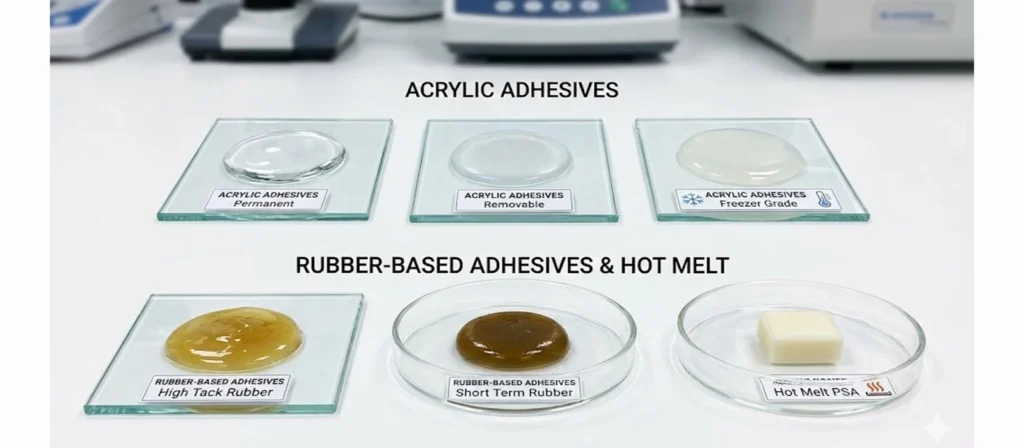

The adhesive layer determines how Pressure Sensitive Labels bond to different containers and how they perform over time. Adhesive selection must consider container material surface texture temperature and expected storage conditions.

- Acrylic adhesives

- Permanent acrylic adhesives for long term bonding

- Removable acrylic adhesives for clean label removal

- Freezer grade acrylic adhesives for cold chain applications

- Rubber based adhesives

- High tack formulations for rough or low energy surfaces

- Short term applications where strong initial grab is required

- Hot melt pressure sensitive adhesives

- Used in high speed labeling operations

- Designed for fast set and strong bond under controlled temperatures

Each adhesive type behaves differently on materials such as glass PET HDPE metal or coated paperboard which is why adhesive testing is critical in food packaging.

3. Release Liners

Release liners protect the adhesive before application and allow labels to dispense smoothly on labeling equipment. While liners are removed during application they strongly influence labeling accuracy and speed.

- Paper based release liners

- Silicone coated glassine paper

- Silicone coated kraft paper

- Film based release liners

- PET film liners for dimensional stability

- Polypropylene film liners for strength and consistency

Film liners are often used for smaller labels or high speed lines where precise dispensing is required.

4. Coatings and Surface Finishes

Some Pressure Sensitive Labels include additional surface treatments to improve durability and appearance. These finishes help protect printed content in real use environments.

- Water based varnish for light moisture protection

- UV varnish for improved scuff resistance

- Film lamination for maximum durability and oil resistance

The choice of coating affects not only appearance but also how readable labels remain after handling storage and transport.

Material overview table

| Label Component | Common Materials | Typical Use in Food Packaging |

|---|---|---|

| Face material | Coated paper PP PE PET | Branding information moisture resistance |

| Adhesive system | Acrylic Rubber based Hot melt | Bonding to glass plastic metal fiber |

| Adhesive performance | Permanent Removable Freezer grade | Long term use clean removal cold storage |

| Release liner | Glassine paper Kraft paper PET film | Smooth dispensing and application accuracy |

| Surface finish | Varnish UV coating Film laminate | Print protection and durability |

By structuring materials this way manufacturers can fine tune Pressure Sensitive Labels for specific food packaging conditions without changing the application method or equipment.

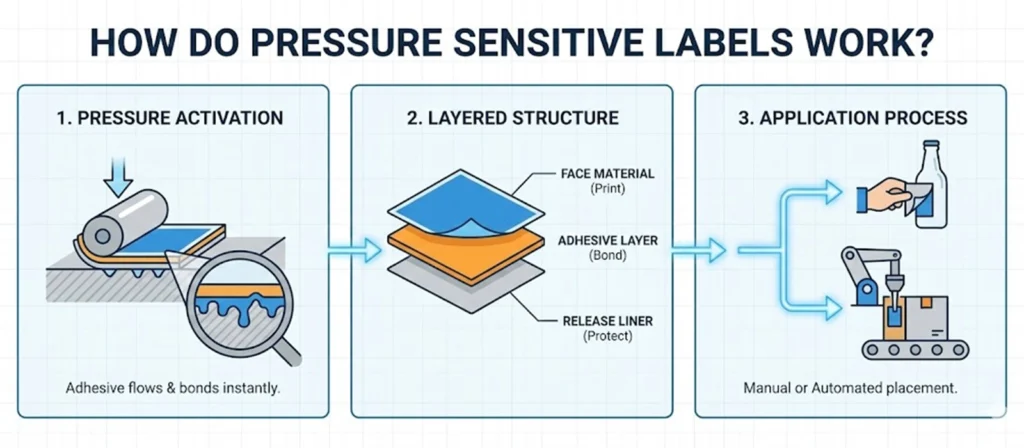

How Do Pressure Sensitive Labels Work

Pressure Sensitive Labels function through a simple but highly controlled mechanism that allows them to bond securely to packaging surfaces with minimal effort.

- Pressure based adhesion Pressure Sensitive Labels activate through physical pressure alone. No heat water or chemical solvents are required. When pressure is applied the adhesive flows into microscopic surface textures creating an immediate and reliable bond on materials such as plastic glass metal and coated paperboard.

- Layered label structure Each Pressure Sensitive Label consists of three main layers. The face material carries printed information and branding. The adhesive layer provides bonding strength and surface compatibility. The release liner protects the adhesive until application and ensures smooth dispensing during labeling.

- Application process The liner is removed to expose the adhesive then the label is positioned on the container and pressed into place. This process can be done manually for small batches or through automated labeling equipment for high volume production ensuring speed consistency and accuracy.

Automated application further improves efficiency by reducing labor variation and improving placement precision. Labeling machines allow Pressure Sensitive Labels to be applied consistently at scale which is why they are widely used in modern packaging lines.

What Food Packaging Uses Pressure Sensitive Labels

Pressure Sensitive Labels play an important role in food packaging by carrying brand identity product type and required information. In most cases labels are applied by equipment during packaging production rather than after distribution which helps ensure consistent logo placement and a uniform brand image across all products.

Common Industry Scenarios That Use Pressure Sensitive Labels

Pressure Sensitive Labels are widely used across different industries where brand identification and standardized labeling are required.

- Consumer goods packaging for brand logos and product identification

- Pharmaceutical packaging for product names batch information and compliance

- Retail and logistics packaging for tracking and visual identification

- Food and beverage packaging where branding and accuracy are essential

Across these industries Pressure Sensitive Labels support consistent logo use and product recognition without changing packaging structures.

Food Packaging Types That Use Pressure Sensitive Labels

In food manufacturing Pressure Sensitive Labels are commonly applied by labeling equipment during the packaging production process. This allows logos and product type information to be added in a controlled environment before products reach filling or distribution stages.

- Beverage bottles and cups

Plastic and glass beverage containers frequently use Pressure Sensitive Labels to display brand logos product names and flavor information. Labels are applied by automated equipment after container forming and filling which ensures alignment and visual consistency across high volume runs. - Burger boxes

Paperboard burger boxes often receive Pressure Sensitive Labels during the box forming or packaging preparation stage. Labels are applied to flat or pre assembled boxes before food contact and are mainly used to display brand logos menu categories or product type indicators. - Salad bowls

Salad bowls made from paper plastic or molded fiber commonly have Pressure Sensitive Labels applied during bowl or lid production. These labels highlight the brand logo product type and basic information allowing ready to use packaging to arrive at food service locations with branding already in place. - Cans and metal containers

Metal cans use Pressure Sensitive Labels primarily for brand logos and product identification when direct printing is not practical. Labels are applied by equipment after can forming and sealing especially for short runs or market specific versions.

| Food Packaging Type | Typical Label Application Stage | Primary Label Use |

|---|---|---|

| Beverage bottles | After forming and filling | Brand logo product type |

| Burger boxes | During box forming or preparation | Brand logo menu category |

| Salad bowls | During bowl or lid production | Brand logo product type |

| Cans | After sealing | Brand logo product identification |

This production based labeling approach explains why Pressure Sensitive Labels are widely chosen for food packaging that requires early branding consistent logo placement and efficient downstream operations.

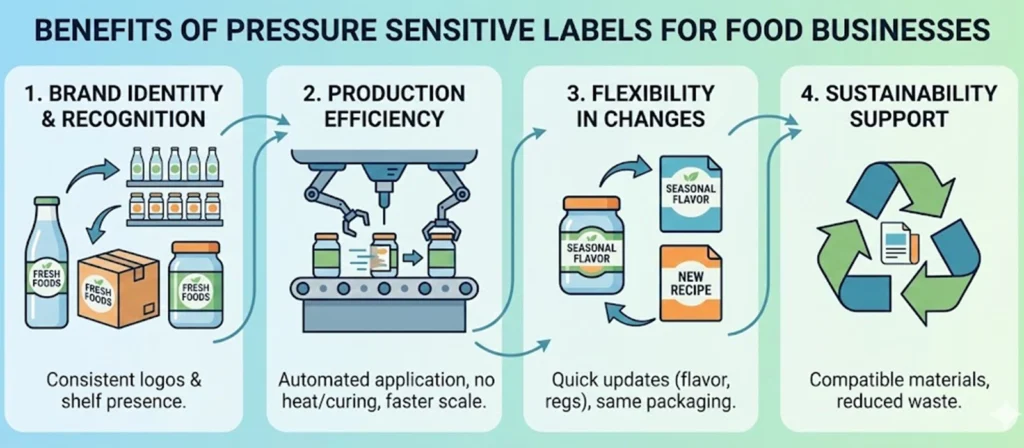

What Are the Benefits of Pressure Sensitive Labels for Food Businesses

1. Supporting Brand Identity and Product Recognition

Pressure Sensitive Labels help food businesses present a clear and consistent brand image across different packaging formats. Logos product names and visual elements can be applied in the same position and size on every unit which improves shelf recognition. This consistency is especially important for businesses managing multiple SKUs or selling through different retail and food service channels.

2. Improving Production Efficiency

Because Pressure Sensitive Labels can be applied by automated equipment they fit easily into modern packaging lines. Labels are added without heat or curing time which reduces downtime and simplifies line setup. This allows food businesses to scale production while maintaining accurate label placement and reducing labor related variation.

3. Enabling Flexibility in Product and Market Changes

Pressure Sensitive Labels allow food companies to update product information without redesigning the entire package. Changes in flavor language regulations or seasonal branding can be handled through label updates while keeping the same packaging structure. This flexibility supports faster product launches and better inventory management.

4. Supporting Sustainable Packaging Strategies

Pressure Sensitive Labels can support sustainability goals when designed with recyclability in mind. Using compatible face materials and adhesives allows labels to be processed together with common food packaging substrates in existing recycling streams. In addition labels reduce material waste by avoiding full package reprints which helps lower overall resource consumption while maintaining clear branding and information.

These advantages explain why Pressure Sensitive Labels remain a practical and strategic choice for food businesses seeking efficiency branding control and responsible packaging solutions.

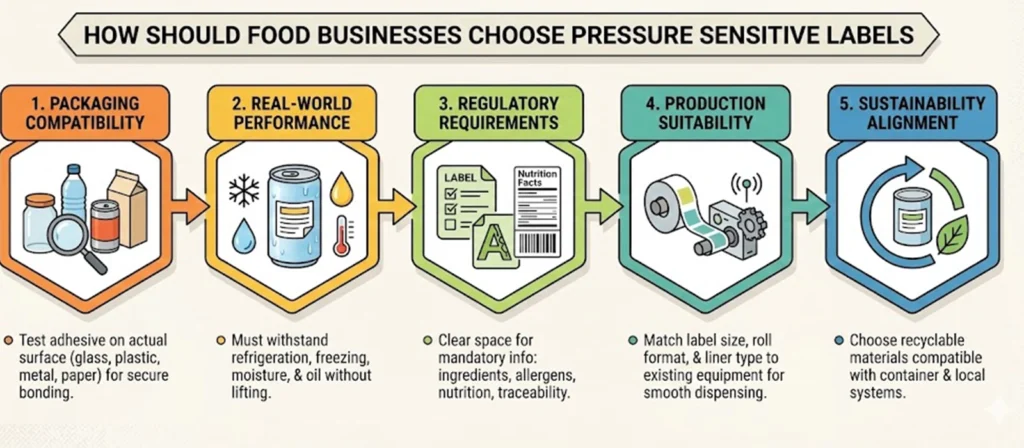

How Should Food Businesses Choose Pressure Sensitive Labels

When selecting Pressure Sensitive Labels food businesses need to look beyond appearance and consider how labels will perform throughout the entire packaging process. The following factors help guide practical and reliable label selection.

- Compatibility with packaging materials

Different containers such as glass plastic metal and paperboard interact with adhesives differently. Pressure Sensitive Labels should be tested on the actual packaging surface to ensure secure bonding without lifting or residue. - Performance in real storage conditions

Food packaging may face refrigeration freezing moisture or oil contact. Labels must stay readable and firmly attached under these conditions to avoid product rejection or compliance issues. - Regulatory and information requirements

Labels often carry mandatory information including ingredients allergens nutrition details and traceability codes. Pressure Sensitive Labels should support clear printing and sufficient space to meet market regulations. - Production line suitability

Label size roll format and liner type must match existing labeling equipment. Smooth dispensing and consistent placement help reduce downtime and labeling errors on automated lines. - Sustainability alignment

When environmental goals are important food businesses should consider recyclable Pressure Sensitive Labels designed to work with the container material and local recycling systems.

Reviewing these points together helps food businesses choose Pressure Sensitive Labels that balance performance compliance efficiency and sustainability.

Conclusion

Pressure Sensitive Labels have become a core component of modern food packaging because they combine reliable adhesion flexible design and efficient application. From beverage bottles to takeaway boxes and cans they support clear branding product identification and regulatory communication without complicating production workflows. When applied by equipment during packaging production they help food businesses maintain consistency and control at scale.

Choosing the right Pressure Sensitive Labels requires attention to materials adhesives application conditions and sustainability goals. By aligning label construction with real packaging environments food businesses can reduce errors improve efficiency and build a stronger and more recognizable brand presence across different product lines.

FAQs

1

What makes Pressure Sensitive Labels different from other label types

⌄

Pressure Sensitive Labels adhere through applied pressure only and do not require heat water or solvents which makes them easy to integrate into both manual and automated packaging lines.

2

Can Pressure Sensitive Labels be used on refrigerated or frozen food packaging

⌄

Yes when the face material and adhesive are selected for cold chain use these labels can maintain adhesion and readability under low temperature and condensation conditions.

3

Are Pressure Sensitive Labels suitable for displaying food logos and branding

⌄

They are widely used for logos and brand visuals because they allow consistent placement clean printing and stable appearance across different packaging formats.

4

Are all Pressure Sensitive Labels recyclable

⌄

Not all label constructions are recyclable but options exist such as paper labels with water dispersible adhesives and recycling compatible film labels designed for common packaging streams.

5

When are Pressure Sensitive Labels typically applied in food packaging

⌄

They are usually applied by labeling equipment during packaging production after containers or boxes are formed and closed which helps ensure consistent placement and fewer errors.