Food packaging plays several roles at the same time. It has to protect the product, support shelf life, carry information, and meet regulatory and customer expectations in different markets. When a new material, structure, or design is chosen, each of these roles needs to be confirmed, not only in theory but under the actual conditions in which the product will be filled, stored, transported, and used.

To make these decisions more objective, companies rely on food packaging testing methods. Instead of judging a film, tray, or bottle only by appearance and basic specifications, they use defined tests to see how the packaging behaves with real products, real processes, and real storage conditions. Chemical methods are used to understand what may migrate from the packaging into food. Physical methods are used to see how the package performs as an object that must be strong, stable, and convenient to handle.

When these methods are planned in a structured way, they turn general expectations such as “safe”, “reliable”, or “shelf stable” into measurable points. Each requirement for the packaging can be linked to one or more test items, and the results can be documented and shared across projects, customers, and markets.

What Are the Requirements for Food Packaging?

Before choosing specific food packaging testing methods, it is important to know what good food packaging is expected to do. Testing is not an isolated activity. Each test should correspond to a clear requirement that matters for real products and real consumers.

It has to keep food chemically safe, protect it from damage, preserve shelf life, remain clean and hygienic, and comply with food-contact regulations. Every test you design should clearly link back to one of these real-world requirements for products and consumers.

In most factories and brands, the key requirements can be grouped into a few main aspects:

- Safety and chemical stability

The packaging must not release harmful substances into the food. This includes components from plastics, paper, coatings, inks, and adhesives. Under typical and worst case conditions such as heating, freezing, high fat content, or long storage, overall and specific migration must stay within legal and internal limits. - Physical protection

The package should keep the product intact from production to consumption. It needs sufficient strength to resist tearing, bursting, leaking, puncture, and seal failure during filling, stacking, transport, and handling. The outer packaging must also protect against compression and impact so that the food is not crushed or damaged. - Shelf life and barrier performance

Many foods are sensitive to oxygen, moisture, light, or loss of aroma. The packaging must provide the right barrier level to slow down oxidation, moisture gain or loss, color change, and flavor loss. The chosen material and structure should support the claimed shelf life under the expected storage and distribution conditions. - Cleanliness and hygiene

Food contact surfaces should be clean and suitable for contact with food. Packaging must minimize the risk of microbiological contamination and visible foreign matter such as dust, fibers, or particles. The way materials are stored, handled, and converted in the packaging plant also needs to support hygienic conditions. - Regulatory and standard compliance

All packaging that contacts food has to comply with applicable food contact regulations and standards in the target markets. This includes legal migration limits, restrictions on certain substances, and any relevant national or industry norms. Many customers or retailers also set their own additional requirements that must be respected.

When a manufacturer designs food packaging testing methods, these requirements are translated into concrete test items and acceptance criteria. For example, migration and chemical analyses are used to confirm chemical safety, mechanical tests such as seal strength, drop tests, and compression tests check physical protection, barrier measurements like oxygen and water vapor transmission rates support shelf life decisions, and microbiological or cleanliness checks verify hygiene. In this way, testing becomes a structured tool to prove that the packaging is not only compliant on paper, but also safe and reliable in actual use.

What Is Food Packaging Testing?

Food packaging testing is the set of planned checks that a company uses to confirm whether its packaging can meet defined requirements. Instead of relying only on supplier promises or experience, the factory uses structured food packaging testing methods to generate objective data and written evidence.

In a typical food business, packaging testing is not a single test but a system. It normally includes:

- Formal tests carried out when a new material, structure, or supplier is introduced

- Periodic verification to make sure existing packaging still performs as expected

- Simple in line checks on production lines, such as seal inspection or visual checks, to catch defects early

These activities are usually linked to specific stages in the product life cycle. During development, packaging testing is used to select materials, compare options, and build the technical file for approvals. During routine production, it supports quality control, complaint handling, and internal or external audits.

Different teams are involved in food packaging testing. Research and development defines what must be tested, quality or technical teams organize and review the tests, purchasing works with suppliers on specifications and certificates, and external accredited laboratories often perform more complex analytical work. The results are stored as reports, certificates, and test summaries that can be traced to specific materials, formats, and batches.

In simple terms, food packaging testing is the bridge between the requirements you set for your packaging and the proof that those requirements are actually met. It makes packaging performance visible, measurable, and auditable, so that decisions about materials and designs are based on facts rather than assumptions.

Types of Food Packaging

Different foods use different packaging materials, and each material brings its own benefits, risks, and testing needs. Choosing suitable food packaging testing methods always starts with understanding which material you are dealing with and what it is expected to do.

Metals

Metals such as aluminum and steel are widely used for cans, ends, and beverage packaging. They seal very well and can protect products through heat processing, long storage, and demanding distribution.

The main concerns are corrosion, interaction between the product and the metal or coating, and damage to internal lacquers. If the food is not compatible with the metal or the coating system, color changes, metallic tastes, gas formation, or loss of integrity can occur. Typical testing focuses on coating adhesion, resistance to the product under realistic conditions, pressure and vacuum performance, seam or double seam integrity, and where needed, migration from coatings into the food.

Plastics

Plastics are used for bottles, trays, films, pouches, and many other formats. They are light, versatile, and can be designed with specific barrier properties, which is why they are so common in modern food packaging.

Key concerns include chemical migration from monomers, additives, plasticizers, inks, and adhesives, as well as gas permeability that may lead to oxidation or loss of carbonation. For plastics, important food packaging testing methods usually include overall and specific migration testing, screening for restricted substances, seal strength and burst tests, impact resistance, and measurements of oxygen and water vapor transmission rates. Durability under heat, cold, and mechanical stress is also checked when the pack will be processed or handled in tougher conditions.

Glass

Glass is less widely used today but still important for sauces, jams, beverages, and premium foods. It is chemically very inert and provides an excellent barrier to gases and moisture. Glass can be reused or recycled many times.

The main drawbacks are weight and fragility. Cracks, chips, or thermal shock can lead to breakage and safety risks. Testing for glass packaging often covers dimensional control, internal pressure resistance for carbonated products, mechanical impact resistance, thermal shock performance, and tightness of the closure system. The cap, liner, and any printed or coated areas may also require their own migration or taint testing, even if the glass itself is not a major chemical risk.

Paper and Board

Paper, paperboard, and cardboard are widely used for paper bags, sleeves, bakery bags, and take-out packaging. They are generally cost effective and can often be recycled or made from renewable sources.

However, paper based materials usually provide limited barrier against moisture, oxygen, and grease unless they are coated, laminated, or combined with other materials. There can also be concerns about contaminants from recycled fibers, printing inks, or adhesives. Relevant food packaging testing methods for paper and board often include strength and compression tests, grease and moisture resistance tests, migration assessments for mineral oils and other potential contaminants, and checks on coating integrity under typical storage and transport conditions.

Multilayer and Composite Structures

Many modern packs combine several materials in one structure, for example a plastic film with an aluminum layer, or paper with a plastic or biopolymer coating. These structures are designed to balance strength, barrier performance, cost, and sustainability.

At the same time, they bring more interfaces, adhesives, and potential failure points. Testing for multilayer and composite packaging usually looks at layer adhesion, seal performance, barrier properties, chemical migration from each relevant component, and how the whole structure behaves under heat, freezing, or mechanical stress.

By understanding the typical characteristics and weak points of each material group, it becomes easier to select targeted food packaging testing methods that focus on the real risks instead of testing everything in the same way.

Common Food Packaging Testing Methods

At a basic level, most food packaging testing methods can be grouped into two main categories: physical methods and chemical methods. This simple classification is enough to guide most daily decisions in factories and projects.

Physical methods focus on how the package behaves as an object. They look at strength, sealing, resistance to damage, and overall integrity during filling, storage, transport, and use. In other words, they help answer whether the packaging can keep the product protected in real handling conditions.

Chemical methods focus on what can move from the packaging into the food. They are used to evaluate migration, potential contaminants, and overall chemical safety of the material in contact with the product. These tests support compliance with food contact regulations and internal company standards.

In practice, companies usually build their test plans by combining these two types of food packaging testing methods. The details of each group, and the specific tests used for different materials and products, will be introduced in the following sections.

Discover Reliable Food Packaging from Million Pack

Million Pack focuses on producing stable, food-safe packaging solutions for a wide range of food and beverage products. From everyday take-away formats to customized brand packaging, our structures are designed to support consistent quality, smooth filling, and dependable performance in real logistics. Explore our catalog to find packaging options that match your product, process, and market needs.

Explore Our Packaging Catalog

Explore Our Packaging Catalog

Chemical Food Packaging Testing Methods

Chemical food packaging testing methods focus on substances that may move from the packaging into the food and on how well the material behaves with a specific product. The aim is to confirm that the packaging is safe, compliant, and suitable for real use conditions. In many companies, these methods are grouped into three practical areas: migration testing, restricted substances testing, and compatibility testing.

Migration Testing

Migration testing evaluates how much material can transfer from the packaging into food or food simulants under defined time and temperature conditions. It is used to understand the overall tendency of a material to release components when it is in contact with a product. Test conditions are chosen to represent realistic or worst case situations for the intended use, such as hot filling, long ambient storage, or frozen distribution. Results from migration testing provide a basic safety check and are often required by food contact regulations.

Restricted Substances Testing

Restricted substances testing focuses on specific chemicals that are subject to legal or internal limits. These can include certain monomers, additives, plasticizers, heavy metals, solvents, or components from inks and adhesives. Instead of looking at the total amount of migration, the test measures the level of each controlled substance and compares it with its permitted limit. This type of testing is essential for demonstrating compliance with detailed food contact rules and for confirming that the final packaging structure respects both regulatory and customer requirements.

Compatibility Testing

Compatibility testing examines how the packaging and the actual food product interact over time. Even when migration and restricted substances are within limits, some combinations of product and packaging can still cause problems such as color change, off odor, loss of barrier performance, or corrosion in metal systems. In compatibility testing, the real product is stored in the intended packaging under defined conditions, then evaluated for visual, chemical, or sensory changes. These studies help verify that the chosen packaging material is not only safe on paper, but also stable and suitable for the specific food, process, and shelf life in practice.

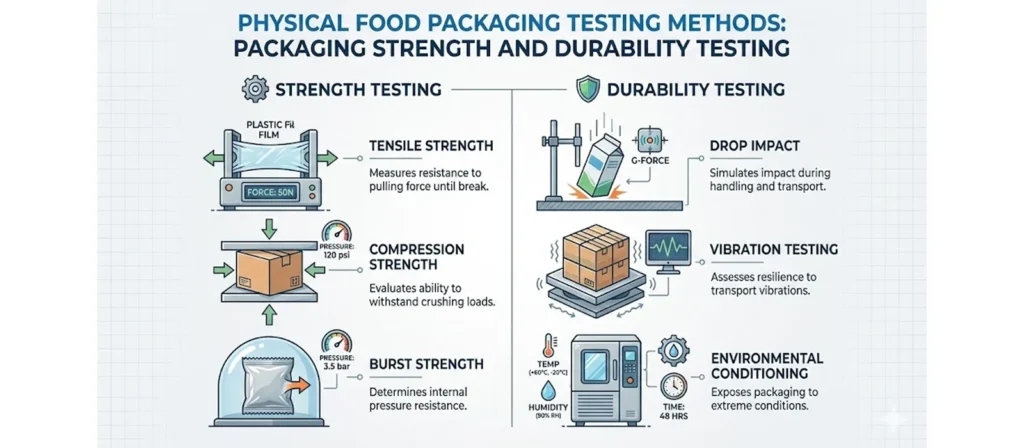

Physical Food Packaging Testing Methods

Physical food packaging testing methods focus on how the package behaves in real handling, storage, and transport conditions. While chemical methods look at what may migrate into the food, physical methods ask whether the package can keep the product protected and easy to use throughout its life cycle. In many companies, these methods are organized into four main areas: functional testing, strength and durability testing, environmental conditioning, and physical hazard evaluation.

Functional Testing

Functional testing checks whether the package actually works as intended in daily use and on the production line. Typical questions include whether the pack is easy to open without tools, whether reclosing features work properly, and whether pouring or dispensing is controlled. For industrial use, functional tests also look at how smoothly the packaging runs on filling, sealing, and labeling equipment, and whether small dimensional variations cause jams or leaks. The goal is to confirm that the package performs its basic functions reliably both for operators and for consumers.

Packaging Strength and Durability Testing

Strength and durability testing evaluates how well the packaging resists mechanical stress. It looks at what happens when packs are stacked, moved, and dropped during logistics. Depending on the packaging format, companies may assess resistance to compression, impacts from drops, and vibration during transport. These tests are usually done on complete packs filled with product or a suitable substitute in order to reflect real loads. By reviewing the results, technical teams can decide whether wall thickness, structural design, or secondary packaging need to be adjusted to reduce the risk of leaks, deformation, or visible damage.

Environmental Conditioning

Environmental conditioning exposes packaging to defined temperature and humidity conditions before or during testing. The aim is to simulate real environments such as refrigerated storage, hot climates, or variable warehouse conditions. For example, paper based materials are often conditioned at specific humidity levels to understand how moisture affects strength, while plastic packs may be evaluated after low temperature storage to see how brittleness changes. Conditioning is not a test on its own, but it helps make strength, functional, and durability tests more realistic by recreating the conditions the packaging will face in practice.

Physical Hazard Evaluation

Physical hazard evaluation looks at the packaging from a consumer safety perspective. It examines whether the pack or its components could create sharp edges, splinters, loose parts, or other hazards during normal use or foreseeable misuse. Typical concerns include the risk of cuts when opening metal or rigid plastic packs, potential choking hazards from small detachable parts, and the consequences of breakage for glass or brittle materials. This evaluation usually combines structured visual inspection with selected physical tests and a documented risk assessment. The outcome is used to refine design details, choose safer materials, and define any necessary warnings or handling instructions.

Together, these physical food packaging testing methods provide a structured way to judge how well a package can protect food and consumers under real life conditions, complementing the information obtained from chemical testing.

Conclusion

In summary, food packaging testing methods are simply a structured way to prove that a specific package can do its job for a specific product. By first clarifying the core requirements for food packaging, then understanding the characteristics of common materials, it becomes much easier to select meaningful tests instead of relying on generic claims. Chemical methods help confirm that contact materials are safe and compliant, while physical methods show whether the structure is strong, stable, and practical in real use. When these elements are planned together in a clear test strategy, you gain a more reliable basis for approving materials, communicating with customers, and supporting long term product quality in the market.

FAQs on Food Packaging Testing Methods

How often should food packaging be tested?

There is no single fixed frequency, but most companies combine three levels. Full validation tests are done when a new material, supplier, or structure is introduced. Periodic verification, such as every one to three years or after significant changes, confirms that results remain valid. Simple routine checks on the line, for example seal or visual inspections, are performed for every batch. The exact plan depends on product risk, shelf life, and how critical the packaging is for safety.

Who is responsible for organizing food packaging testing methods?

Responsibility is usually shared. Packaging suppliers provide basic data, declarations, and initial test reports. The food manufacturer or brand owner defines the final requirements for the specific food and decides which extra tests are needed. Quality or technical teams coordinate the test plan, select laboratories, and review results. In the end, the brand owner is normally seen as responsible for proving that the chosen food packaging testing methods are suitable and that the packaging is safe.

Do all packaging materials need the same tests?

No. Different materials and products require different food packaging testing methods. For example, plastics often focus more on migration and barrier, metals on corrosion and coating performance, and paper on potential contaminants from recycled fibers and coatings. The test plan should always be tailored to the actual food, contact time, temperature, and market rather than copied from another product.

Can I rely only on supplier certificates instead of testing myself?

Supplier certificates and declarations are an important starting point, but they are rarely enough on their own. Most companies still perform at least some independent checks, especially for high risk products, long shelf life items, or critical materials. Limited in house tests or external laboratory work help verify that the packaging behaves as expected in the company’s own process and with its specific foods, rather than only under generic conditions.

What’s the difference between migration testing and compatibility testing?

Migration testing evaluates whether chemical substances transfer from packaging into food or food simulants under controlled conditions, typically for legal compliance. Compatibility testing looks at how the packaging interacts with the actual food over time, checking for issues like odor transfer, staining, or degradation. Both are important, but they answer different questions.