The core difference between single-wall and double-wall cups lies in insulation. A double wall cup has an extra layer that traps heat, keeping drinks warmer and hands cooler. A single wall cup has only one layer, which offers less protection and often requires an additional sleeve. The distinction is structural and functional, and it directly affects how the cup performs in real-world use.

However, the decision between a single wall vs double wall coffee cup goes beyond just counting layers. In packaging, context is everything. Whether you’re supplying cafés, food stalls, event vendors, or corporate branding, understanding the difference between single wall and double wall coffee cups helps ensure you’re choosing the right cup for the job. Single wall cups are lightweight, budget-friendly, and easy to customize in bulk. Double wall cups cost more but offer better heat insulation, often removing the need for sleeves or extra materials.

But the single wall vs double wall coffee cup decision isn’t purely technical, it’s strategic. In the packaging world, every choice sends a message. Selecting between these two cup types involves balancing cost-effectiveness, sustainability targets, user comfort, and the unique demands of your situation. The right cup doesn’t just hold coffee, it enhances the entire brand experience.

Picture this: You’re handing out hot drinks at a winter event, and you’ve chosen a single wall coffee cup. It’s too thin to handle the heat, guests awkwardly shift the cups between fingers, and some cups crumple under pressure. That’s the kind of packaging misstep that a double wall coffee cup could’ve prevented, one small choice that changes the whole impression.

What is a Single-Wall Cup?

The single wall cup is the most common and widely recognized type of paper cup used in packaging today. As the name implies, it is constructed from a single layer of paperboard, typically coated with a thin internal lining such as polyethylene or PLA to provide basic liquid resistance. This straightforward design emphasizes simplicity and efficiency.

In terms of manufacturing, a flat paperboard blank is die-cut, rolled into a cone shape, and sealed along the side. A circular paper disc is then attached to form the base, creating a leak-resistant container with minimal material input. Because of this streamlined process, single wall cups are highly economical to produce and distribute, making them a preferred choice in cost-sensitive or high-volume operations.

Another advantage of single-layer cups is their smooth outer surface, which is ideal for high-quality printing. They can perfectly showcase branding, logos, or promotional designs. While not the best choice for hot drinks (requiring a sleeve or additional insulation), they are perfect for cold drinks, and their lightweight, low-cost nature makes them a versatile, universal single-use packaging option, not just limited to beverage packaging.

What is a Double-Wall Cup?

A double wall cup is a type of paper cup designed with two layers of paperboard rather than one. The inner wall holds the liquid, just like in a single wall cup, while the outer wall wraps around it, creating a small air gap in between. This extra layer acts as built-in insulation, helping to maintain the temperature of the contents while keeping the outer surface cooler to the touch.

The manufacturing process for double wall cups is more involved. After the inner cup is formed using the same method as a single wall cup, a second paperboard sleeve is wrapped and adhered to the outside. This not only improves heat retention but also strengthens the cup’s structure, making it more rigid and comfortable to hold without needing a separate sleeve.

Double wall cups are commonly used in packaging for hot beverages, high-end takeaway service, and premium branding applications. Their layered design allows for enhanced print finishes and a more substantial feel in hand. While they come at a higher production cost, they offer a better user experience where heat protection, durability, and perceived value are important.

Single-Wall vs. Double-Wall

With the basics covered, it’s helpful to see how these two cup types compare across the features that matter most in packaging decisions. The table below organizes those differences clearly, so you can assess each option at a glance before we explore the details one by one.

| Feature | Single-Wall Cup | Double-Wall Cup |

|---|---|---|

| Structure | Single layer of coated paperboard | Two layers with insulating air gap |

| Primary Use | Cold drinks, dry snacks, budget packaging | Hot drinks, takeaway service, premium packaging |

| Insulation | Minimal, heat transfers easily | High, retains heat effectively |

| Customer Comfort | Can feel hot to touch, often needs a sleeve | Comfortable to hold without additional protection |

| Structural Strength | Lightweight, less rigid | More durable and supportive feel |

| Cost | Lower production cost | Higher cost due to added material and processing |

| Branding Surface | Smooth, ideal for full-surface printing | Printable, but may be textured due to layering |

| Eco-Footprint | Less material, but may require a sleeve | More material, but no extra accessories needed |

| Application | High-volume service, short-term or cold-use scenarios | Heat-sensitive products, premium brand presentation |

Insulation and Heat Retention

Single wall cups provide minimal thermal insulation due to their single-layer construction. Heat from the liquid inside quickly escapes through the paperboard, leading to rapid temperature loss. Beverages served in this type of cup tend to cool down much faster, which may not be ideal for products expected to stay warm over time.

Double wall cups, by design, offer a significant improvement in heat retention. The added outer layer, separated from the inner wall by a thin air gap, acts as an insulating barrier. This slows the rate of heat dissipation, helping to maintain the internal temperature of the liquid for a longer duration. It ensures that hot beverages remain hot well beyond initial serving, making it more suitable for packaging that requires thermal consistency.

In terms of insulation and heat retention alone, the double wall structure clearly outperforms the single wall design by extending the warmth lifespan of the product.

Environmental Impact & Sustainability

Single wall cups are generally made from virgin fiber paperboard sourced from responsibly managed forests. To provide liquid resistance, they are commonly lined with polyethylene or polylactic acid. Because the cup consists of a single structural layer, the material composition is relatively simple. This simplicity helps improve recyclability, especially when using new water-dispersible or compostable liners. Some producers are also moving toward plant-based bio-coatings, which reduce reliance on fossil fuels and improve composting compatibility. However, traditional polyethylene-lined paper is still a challenge for most recycling facilities, where plastic coatings limit fiber recovery and often result in the cup being sent to landfill.

Double wall cups add a second layer, which introduces additional material types and bonding agents. While the inner cup is similar in composition to a single wall cup, the outer layer may be made from kraft board, recycled paper, or alternative fibers such as bamboo. This allows for partial use of recycled content or non-wood sources. However, the combination of materials and adhesives makes separation more complex during recycling. In many waste systems, these cups are treated as non-recyclable due to their multi-material structure, even if each layer on its own is technically recyclable.

However, this doesn’t mean double wall cups are inherently bad for the environment. Many brands offer eco-friendly versions of both types, so the key is to source responsibly and encourage proper disposal. If you’re evaluating eco-friendly drinkware overall, check out this comparison: Paper Cups vs Plastic Cups

From a materials perspective, single wall cups are simpler and generally easier to recover in circular systems, provided the lining and disposal infrastructure are compatible. Double wall cups offer sourcing flexibility and enhanced performance but require more sophisticated recovery processes to achieve the same level of environmental benefit.

Customer Experience and Tactile Feel

Single wall cups provide a lightweight and minimal design that works well in fast service or cost-sensitive settings. However, because of their thin construction, they can feel less stable in the hand. When holding hot or filled cups, the material may flex slightly, which can create a perception of lower quality. This subtle feedback can influence how customers view the product or brand. If used for hot beverages without any additional insulation, the surface can become uncomfortably hot, leading to a rushed or distracted drinking experience.

Double wall cups deliver a noticeably more solid and substantial feel. The second layer adds structure and firmness, making the cup feel more reliable and well-built. This often enhances the overall perception of quality. The thicker walls also prevent the surface from heating up quickly, which contributes to a more controlled and confident handling experience. This kind of tactile difference is particularly important in settings where packaging reflects brand identity or product value.

In contexts where physical touch contributes to user satisfaction, such as premium coffee service or branded event catering, double wall cups offer a clear advantage in how the product is received and remembered.

Price and Cost Considerations

Single wall cups are generally more affordable in terms of unit cost. Their single layer structure requires less paper material, fewer production steps, and no additional bonding processes. This makes them ideal for operations focused on cold beverages, short term use, or high volume service with tight budgets. They also save on storage and shipping due to their lighter weight and more compact stacking.

Double wall cups, while more expensive per unit, can offer greater value when operational efficiency is considered. Because insulation is built in, there is no need for separate sleeves or double cupping. This simplifies inventory since only one item needs to be stocked and tracked. It also reduces the space required for storage. During busy service periods, eliminating the step of adding a sleeve allows staff to serve customers faster, improving throughput and customer satisfaction. Additionally, using an integrated cup reduces waste and prevents unnecessary sleeve use, especially when customers take more than one.

The most cost effective option depends on your business context. For cold drink services or high turnover models, single wall cups offer straightforward savings. For hot beverage operations where temperature control and presentation are key, double wall cups may result in lower overall cost through improved workflow and reduced material usage.

Structural Strength and Durability

Single wall cups are built with a single layer of coated paperboard, which provides basic rigidity but limited resistance to external pressure or deformation. When filled with hot or heavy liquids, the cup may flex or crumple slightly if gripped too tightly. This can make it less reliable in handling, especially in situations where customers are on the move or not particularly careful with how they hold the cup. In high-traffic service environments, this level of fragility can occasionally lead to spills or dropped beverages.

Double wall cups, by comparison, offer noticeably greater structural integrity. The additional outer layer not only serves as insulation but also reinforces the body of the cup, reducing the chance of buckling or collapsing under pressure. This added thickness gives the cup a firmer hand-feel and increased resistance to squeezing or impact during transport. It also contributes to a more premium, stable impression of quality, especially for takeaway service or catered events where the cup may be handled for an extended period.

From a structural standpoint, double wall cups are better suited for packaging scenarios that demand a higher level of durability, especially where physical handling and transportation are more intense or prolonged.

How to Choose the Right Coffee Cup for Your Needs

Choosing the right type of paper cup is not just a sourcing decision. It is a packaging strategy that affects operations, customer satisfaction, brand perception, and sustainability. To make the best choice, you need to start with one question: what kind of experience does your product require?

If you operate in a fast service environment such as food trucks, festivals, or high volume beverage counters where speed and cost are critical, single wall cups are often the best match. They are lightweight, easy to store, quick to serve, and inexpensive to produce. For cold beverages or short use products, their simplicity makes them highly effective.

However, for businesses serving hot beverages, especially in premium contexts such as branded cafes, corporate catering, or specialty coffee shops, the double wall cup offers greater long term value. It provides better insulation, removes the need for sleeves, and communicates quality through both form and function. This is important in settings where customer perception and visual presentation are part of the brand experience.

You should also consider the logistical side of cup selection. Storage space, staff workflow, and waste handling all influence long-term efficiency. For example, stocking both cups and sleeves takes up more room and requires tighter inventory control. In high-pressure service environments, relying on staff to double cup consistently can slow down operations. Waste management is another factor, especially if your facility deals with multi-layer materials or compostable coatings. The most suitable cup is one that integrates smoothly with your existing service flow, supports your environmental goals, and meets customer expectations without unnecessary complexity.

There is no single solution that fits all scenarios. The best option is the one that supports your business model while delivering on product performance and brand consistency.

FAQ

Is PLA lining better than PE for sustainability?

PLA, a plant-based bioplastic, is often considered more sustainable than PE because it is compostable under industrial conditions and derived from renewable resources like corn starch. PE, made from petroleum, is more durable but difficult to separate from paperboard during recycling. However, PLA’s sustainability depends on whether commercial composting facilities are available in your region. If not, it can behave like plastic waste. In contrast, PE-lined cups are more widely used but less environmentally friendly. So, PLA has better potential but only when supported by proper waste management infrastructure.

Why do some brands still use single wall cups for hot drinks?

Many brands stick with single wall cups for hot beverages due to cost efficiency and operational simplicity. They are cheaper to produce and easier to store in bulk. For businesses that prioritize speed, low pricing, or offer limited hot drink options, adding a sleeve to a single wall cup can be more flexible than managing multiple cup types. In high-volume settings like quick-service restaurants or large events, this approach helps streamline inventory while keeping costs predictable. The trade-off is lower heat retention and a less premium feel compared to insulated alternatives.

What kind of printing options are available for each type?

Single wall cups offer a smooth, uninterrupted surface that’s ideal for high-resolution, full-color printing. They are a top choice for brands looking to maximize logo visibility or run detailed promotional graphics. Double wall cups also support branding, but the outer layer may have a matte or textured finish, which slightly limits certain printing methods. Some double wall options use pre-printed outer wraps, which can still deliver strong branding impact but may involve longer lead times or higher order minimums. Ultimately, both can be customized effectively with the right design and supplier.

Are double wall cups worth it?

Double wall cups are worth the investment in situations where insulation, heat retention, and presentation matter. Their built-in air gap keeps drinks hot longer and removes the need for extra sleeves, which improves operational efficiency. They also feel sturdier and more premium in the hand, which enhances brand perception. While the unit cost is higher, the long-term value is seen in better customer experience and reduced accessory usage. For cafés, catering, or takeaway services where quality and comfort are part of the offering, double wall cups often justify their higher price.

Can paper cups be recycled if they have a lining?

Technically, yes, but it depends heavily on the type of lining and local recycling capabilities. Most paper cups have a thin PE or PLA layer to prevent leaks. Standard recycling systems struggle to separate the plastic from the paper fibers, which means many lined cups are sent to landfill. However, some modern facilities and specialist recyclers can process these materials. Cups with water-based or compostable linings are easier to handle but require the right infrastructure. Always check regional guidelines, as even recyclable materials can become waste if systems aren’t equipped to manage them.

Do double wall cups affect how drinks taste?

Not directly. Both single wall and double wall cups use food-grade coatings like PE or PLA that do not interfere with the flavor of the beverage. However, double wall cups maintain temperature longer, which means the drink stays closer to its intended serving condition. This can subtly affect how flavors are perceived, especially for specialty coffees or teas where temperature influences aroma and taste clarity. In this way, while the material itself doesn’t alter taste, the thermal stability of double wall cups can help preserve the intended sensory experience.

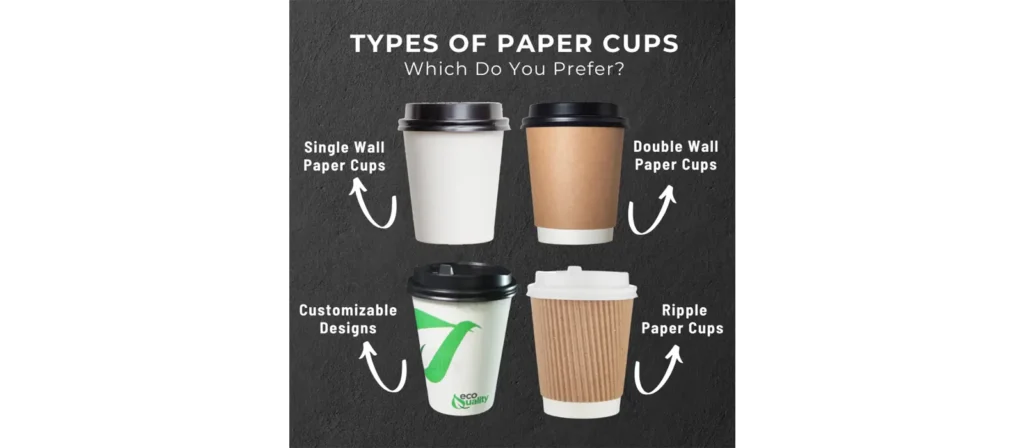

Are ripple wall cups the same as double wall cups?

Ripple wall cups are a type of double wall cup but with a key difference in structure. Instead of a smooth outer layer, they feature a corrugated or “rippled” surface that adds extra insulation and provides a better grip. Like standard double wall cups, they reduce heat transfer and eliminate the need for sleeves. However, their texture gives them a more tactile and visually distinct appearance, which can influence branding or user experience. Ripple wall cups are often used in takeaway coffee service where both insulation and hand comfort are important.

Conclusion

Choosing between single wall and double wall cups is more than a matter of structure. It is a decision that reflects how your business balances cost, function, brand identity, and customer expectations. Each option has its advantages. Single wall cups offer simplicity, efficiency, and cost savings, making them ideal for cold beverages or fast-paced service. Double wall cups, on the other hand, provide insulation, durability, and a more premium impression that aligns with hot drink service and high-end packaging goals.

Ultimately, the right choice depends on your context. Consider how your cups will be used, how they support your operations, and what message they send to your customers. By aligning the packaging format with the purpose it serves, you turn a simple paper cup into a tool that supports both product quality and business performance.