When you see the term “food grade” on a kitchen container or food-processing tool, do you know what it really means? In the U.S., what does food grade mean is more than a label.it’s a safety standard. A food-grade material has been evaluated to ensure it won’t contaminate food under expected use. In this article, we’ll define food grade, explain how it differs from food safe, look at the FDA’s role, and share practical ways consumers in the U.S. can apply this knowledge. Understanding what does food grade mean can help you make safer, smarter choices in both everyday life and business.

What Does Food Grade Mean

The phrase “food grade” might sound simple.But in truth, its meaning has layers, especially in the U.S. marketplace. At its most basic, “food grade” means that a material or product is deemed suitable for contact with food (directly or indirectly) based on how it was manufactured, what it is made of, and how it will be used. For instance, many manufacturers describe food‑grade stainless steel, food‑grade plastic, food‑grade silicone or food‑grade lubricants.The key idea is that such materials must not introduce harmful substances into the food, must withstand cleaning or usage conditions, and must maintain integrity .I.e., not degrade, corrode, or leach chemicals.

However, what does food grade mean in a regulatory sense is somewhat more complex. In the U.S., the FDA regulates “food contact substances” (FCS) and “food contact materials” under federal law. A material may be considered food‑grade if it meets the criteria established for food contact applications, such as migration limits, composition, intended use, temperature and cleaning conditions. For example, one guidance says: “To be considered a food‑grade material, the material needs to be either safe for human consumption or safe to be in direct contact with food.”So when you see “food grade” on a product in the U.S., ideally it suggests that the manufacturer or supplier is claiming compliance with those standards.

That said, seeing the label “food grade” is not a guarantee of universal safety in all conditions—that’s why knowing what does food grade mean also involves paying attention to the specific conditions of use (temperature, food type, cleaning methods, etc.).

Food Grade vs Food Safe – What’s the Difference

| Feature | Food Grade | Food Safe |

|---|---|---|

| Definition | A material that is suitable for contact with food based on its composition | A material that is not only food grade but also safe under actual usage conditions |

| Regulatory Basis | Generally defined by FDA (e.g., 21 CFR Parts 174–186) | Inferred through testing, documentation, and compliance with intended use |

| Scope of Application | Focuses on what the material is made of | Focuses on how the material is used in real-world scenarios |

| Guarantees Safety? | Only if used as intended; not a blanket safety label | Yes, when the material is used according to validated conditions |

| Examples of Use | Food-grade plastic bottle for storing dry grains | That same bottle used for acidic liquids at high temperatures may not be food safe |

| Testing Requirements | May be based on material standards alone | Must include performance testing under real-world conditions |

| Common Misconception | Assumed to always mean completely safe | Often overlooked even though it ensures real-life safety |

| Who Verifies? | Manufacturer claims compliance with FDA regulations | Requires verification by manufacturer or third-party under actual use cases |

| Label Visibility | Frequently labeled on products (“food grade”) | Less often visible; usually found in technical documentation |

| Best Practice | Start with food-grade material | Confirm it is also food safe for your specific usage conditions |

Types and Examples of Food Grade Packaging Materials

Choosing the right food grade packaging material is a critical decision that affects product safety, shelf life, cost efficiency, and brand identity. Below are the most commonly used types in the food industry today:

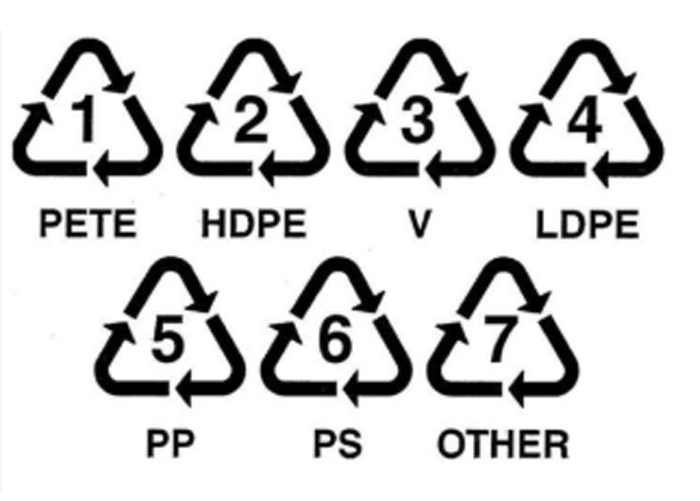

1. Plastic Packaging Materials (PE, PP, PET)

Plastic remains the most widely used material in food packaging, with PE (Polyethylene), PP (Polypropylene), and PET (Polyethylene Terephthalate) being the most popular variants.

- Applications: Commonly used for snack bags, biscuit wrappers, frozen food pouches, and household cling films.

- Characteristics: Moisture-resistant, oil-resistant, transparent, flexible, and relatively cost-effective.

2. Paper-Based Packaging (Kraft Paper, White Cardboard, Coated Paper)

Paper is one of the most recognized food grade packaging materials due to its eco-friendly nature, recyclability, and biodegradability, making it a core component in the push for sustainable packaging solutions.Its lower cost compared to other materials is also a reason why it is more favored as a packaging material.

- Characteristics: Usually treated with food-safe coatings to resist grease and moisture. Offers a premium look and feel that appeals to brands and environmentally-conscious consumers.

- Applications: Frequently used for sandwich wraps, bread sleeves, takeaway boxes, and fast-food containers.

3. Aluminum Foil and Composite Packaging

Aluminum foil and its laminated structures with paper or plastic are widely adopted due to their excellent barrier properties.However, it is difficult to degrade, and improper handling can cause long-term environmental pollution.

- Characteristics: Provides outstanding protection against moisture, light, and odor — ideal for preserving food quality and extending shelf life.

- Applications: Used for coffee bags, tea pouches, seasoning sachets, and ready-meal pouches.

4. Recycled Materials

Incorporating recycled paper ,glass or plastics into food grade packaging requires strict regulatory compliance. This includes source traceability, segregation, decontamination, migration testing, leaching evaluation, and official food safety audits to confirm suitability for food contact.

- Characteristics: Helps reduce resource waste and environmental impact but relies heavily on a controlled and well-regulated recycling system.

- Applications: Common examples include glass bottle, recycled paper takeaway containers, trays, and delivery bags.

5. Biodegradable and Compostable Packaging Materials

Made from renewable plant-based sources such as PLA (polylactic acid), bagasse (sugarcane fiber), or corn starch, these materials are designed to break down under composting conditions, making them an eco-conscious alternative to traditional plastics.This is a nice ideal for restaurants, catering, and food delivery services seeking sustainable packaging.

- Characteristics: Certified for home or industrial composting; decomposes in about 90 days in commercial facilities (longer in home settings); PFAS-free; compliant with international standards; supports sustainable brand positioning.

- Applications: Ideal for disposable food containers, plates, soup bowls, and takeaway wraps.

All of the above materials must be manufactured by certified producers and validated through migration testing and food safety assessments to qualify as food grade packaging. For exports, manufacturers must also obtain regional certifications to comply with the destination country’s food contact regulations.

FDA’s Role in Regulating Food Grade Materials

In the U.S., one cannot fully grasp what does food grade mean without understanding how the Food and Drug Administration (FDA) regulates materials that come into contact with food. The FDA’s authority stems primarily from the Federal Food, Drug, and Cosmetic Act (FD&C Act) which empowers the agency to regulate food additives, indirect additives and food contact substances. For food‑contact applications, the FDA uses the concept of a “food contact substance” (FCS) defined under section 409 of the FD&C Act and corresponding regulations.

What does all this mean for food grade materials practically? First, the FDA requires that materials used in contact with food must not cause the food to be adulterated, misbranded, or to become unsafe. In other words, a food‑grade product must comply with FDA regulations to avoid the food being deemed unsafe. For example, the FDA states: “Under federal law, a food contact substance that is a food additive must be authorized for that use before it is marketed in the U.S.”

Second, the FDA publishes inventories and lists of substances that are authorized for food contact uses, including the “Inventory of Food Contact Substances (FCS) Listed in 21 CFR.” These lists help manufacturers and consumers verify whether a material’s composition has been reviewed or listed.

Third, the FDA issues guidance regarding how to “determine the regulatory status of components of a food contact material.” In practice, manufacturers must consult the rules to check whether their material is exempted from a food contact notification (FCN) or other requirement.

Key Regulations: Understanding Title 21 CFR

To deepen your grasp of what does food grade mean in the U.S., it is helpful to explore some of the key regulatory sections where food‑contact materials are addressed. Under Title 21 of the Code of Federal Regulations (CFR), Parts 174 through 186 cover indirect food additives and other food contact materials. For example:

- Part 174 covers indirect food additives: general; Part 175 covers adhesives and components of coatings; Part 176 covers paper and paperboard components; Part 177 covers polymers; and so on. 维基百科+1

- The FDA inventory of authorized substances is aligned with 21 CFR lists. U.S. Food and Drug Administration+1

A further nuance: being listed or authorized under 21 CFR does not guarantee the material is safe under all use conditions. Manufacturers must verify that a material is safe for the intended food type (acidic, oily, hot), temperature, time of contact, cleaning or sanitizing methods. As discussed earlier, the difference between “food grade” and “food safe” hinges on fitness‑for‑purpose. For instance, a polymer listed under Part 177 may be approved for certain usages (e.g., bakery pan contact at moderate temperatures) but not necessarily for extreme conditions like high‑temperature steam or highly acidic foods unless specifically validated.

How to Identify and Verify Food Grade Materials in the U.S.

Having explored what does food grade mean, you might be asking: how do I as a consumer,or small business owner,verify that a product claiming “food grade” is actually safe and suitable? Here are practical steps and guidance:

- Look for regulatory references

When a product or material says “food grade”, check whether it references compliance with relevant U.S. regulations such as 21 CFR Parts 174–186, or whether the manufacturer states that it is “FDA compliant” for food contact. As noted above, “FDA‑compliant” is often used in industry to mean the material meets the FDA’s food contact criteria. interstateam.com - Ask for a Declaration of Compliance or Certificate

Many manufacturers provide a “Declaration of Compliance” (DOC) or certification showing that the material is evaluated for food contact use under expected conditions (temperature, cleaning methods, food type). This may include test results for migration, chemical resistance, or suitability for acidic/oily foods. - Check suitability for use conditions

Even a food‑grade material may not be safe if used outside its intended parameters. For example: high temperature cooking, acidic foods, oily/fatty contact, or industrial cleaning chemicals may degrade some materials. Therefore ask: Is this material rated for hot contact? Is it rated for direct contact with acidic foods? Is it safe for microwave use? These conditions matter when interpreting what does food grade mean. - Check what type of food contact is intended

Some materials may be rated for indirect food contact (e.g., packaging liner) but not direct contact. Others may be safe for dry ingredients but not for liquid or hot foods. Understanding how the material will be used will clarify whether the “food grade” label applies. This is critical because the term food safe emphasizes that the material is safe in context of use, not just by composition. - Review cleaning and maintenance instructions

Materials contacting food must be cleaned and sanitized. The compatibility of the material with cleaning chemicals, abrasion, high temperatures, or repeated cycles influences whether the product remains “food safe”. A component may be “food grade” in the sense of its composition, but if it fails to withstand cleaning it may become unsafe over time. - Be aware of marketing terms vs actual regulatory compliance

The phrase “food grade” can sometimes appear as marketing rather than a regulatory guarantee. Always verify whether the claim is backed by documentation or third‑party testing. The fact that the FDA allows materials to be used under specific conditions means the burden is on the manufacturer or purchaser to ensure fit for purpose.

Common Misconceptions About Food Grade Materials

Even with a solid grasp of what does food grade mean, there remain widespread misconceptions that can lead consumers astray. Let’s clarify a few of these.

Misconception 1: “Food grade” equals universal safety under all conditions

As mentioned earlier, a material may be designated food grade for certain conditions but not others. A container might be safe for storing room‑temperature dry foods, but not hot liquid or for microwave use. The phrase food safe is often more relevant when specifying that suitability. An industry article succinctly states: “Just because that material is permitted to come in contact with food, it doesn’t necessarily mean it is food‑safe.” FoodSafetyTech

Misconception 2: “Food grade” and “BPA free” mean the same thing

The absence of BPA is one facet of material safety, but it does not alone determine whether a material is food grade or food safe. A food grade plastic may still allow migration of other substances or degrade under certain conditions. Thus when interpreting what does food grade mean, it’s important to look beyond just one chemical and consider the full safety profile.

Misconception 3: If something is labeled “food safe”, it doesn’t need further verification

Even when labeled “food safe”, usage conditions matter. For example, the symbol of a wine glass and fork might indicate food contact suitability in some jurisdictions, but it does not automatically guarantee safety for all food types, temperatures, or repeated use. Wikipedia+1

Misconception 4: All kitchenware marked “food grade” is FDA‑approved

The phrase “FDA approved” is often misused. The FDA generally does not “approve” a finished kitchen utensil for food contact unless it involves a regulated additive or coating. What is more accurate is that the material used is “authorized” or “acceptable” under food contact regulations. The presence of an “FDA approved food grade plastic” label should prompt you to check what that means in context. acplasticsinc.com

Misconception 5: International standards are equivalent to U.S. standards

Because “food grade” is a term used globally, some consumers assume that a food grade claim made abroad equates directly to U.S. FDA compliance. But regulatory frameworks differ significantly. Therefore when buying for the U.S. market or using domestically, ask whether the material meets U.S. regulations,not just generic “food grade” claims.

By addressing these misconceptions, you will better understand what does food grade mean and how to apply that knowledge effectively rather than rely on vague labels.

U.S. vs International Standards – EU Compared

To further contextualize what does food grade mean, it’s instructive to compare how the U.S. regulatory framework aligns or differs with other major jurisdictions like the European Food Safety Authority (EFSA) and the regulatory system in China.

In the European Union, for example, materials intended to come into contact with food are regulated under Regulation (EC) No 1935/2004 which requires materials to be safe, not change food composition, and not degrade in a way that impairs food safety. There are also specific measures for plastics, such as Commission Regulation (EU) 10/2011 for plastic materials.

For a U.S. consumer, this means that when imported products are labelled “food grade”, it is wise to check whether they meet U.S. FDA regulations, not just international ones. The regulatory threshold, documentation required, testing protocols, usage conditions and enforcement mechanisms differ. In practice: a container imported from overseas marked “food grade” might still not satisfy the exact U.S. regulatory requirements unless the supplier has verified compliance.

Future Trends in U.S. Food Grade Regulations

Looking ahead, the question what does food grade mean is likely to become even more significant as materials science evolves, sustainability concerns grow, and regulatory scrutiny intensifies. Here are some of the trends you should watch:

- Sustainability and recyclable materials in food contact use:As demand for eco‑friendly packaging increases, manufacturers are exploring novel materials (bio‑based plastics, recycled plastics, plant‑derived polymers) labeled “food grade”. But for U.S. compliance, these materials still need to meet migration, compositional and cleaning‑compatibility standards. The phrase “food grade” in this context may require extra verification because the technology is newer.

- Increased focus on PFAS, microplastics and chemical migration:Regulators are paying more attention to emerging contaminants in food contact materials. When you ask what does food grade mean, you may soon need to ask whether the material is free of PFAS, has low migration potential, and is validated for new usages.

- Greater emphasis on fitness‑for‑purpose testing:The industry is shifting from merely “listed as food contact acceptable” toward requiring evidence that the material is safe under the actual usage scenario. That means the distinction between “food grade” and “food safe” becomes more important and regulated.

- Digital traceability and transparency:Suppliers and manufacturers may increasingly provide digital certification, traceability logs, and detailed documentation about the materials they use, cleaning regimes, contact conditions, etc. Consumers may see QR codes or detailed “Declaration of Compliance” PDFs alongside the term “food grade”.

- Harmonization and global standards:As global trade continues, there is pressure toward aligning food‑contact material standards internationally. For U.S. consumers, this could mean clearer cross‑border statements of food grade compliance, though U.S. FDA standards will likely remain the benchmark.

In this evolving environment, understanding what does food grade mean becomes not only a matter of checking a label—but staying informed about how materials are changing, how regulation is adapting, and how your intended use may affect safety.

Conclusion

To wrap up: when you ask what does food grade mean, you’re essentially asking: does this material or product meet the standards and conditions necessary for safe contact with food in the U.S.? The answer hinges on several factors: the material’s composition, regulatory compliance (e.g., under 21 CFR), intended use, cleaning and usage conditions, and whether the manufacturer has verified fitness for purpose. We’ve shown the difference between food grade and food safe, illustrated how the FDA regulates food contact materials, explored key U.S. regulations, reviewed recent trends and misperceptions, and offered practical advice for verifying claims.

Ultimately, being an informed consumer or business owner means not just looking for the label “food grade” but digging into what it truly means in your specific context. By doing so, you’ll protect your health, make smarter purchases, and avoid potential pitfalls. Understanding what does food grade mean empowers you to choose materials that genuinely meet your safety needs,not just in name, but in practice.

FAQs:

- Can food grade plastic be used in the microwave?

Not always. While food grade plastic is generally safe for food contact, it doesn’t automatically mean it’s microwave-safe. Microwaving can cause certain plastics to degrade or leach chemicals into food, especially if not rated for high temperatures. Always look for both “microwave safe” and “food safe” labels before using in a microwave. - How do I know if a material is FDA-approved as food grade?

Check for a manufacturer’s declaration referencing compliance with FDA regulations—usually Title 21 CFR Parts 174–186. Many reputable suppliers will also provide a Certificate of Compliance or reference their materials in the FDA’s Food Contact Substance (FCS) Inventory. Note that FDA does not “approve” finished products, but rather the materials used in food contact applications. - Is food grade the same as BPA-free?

No, these terms refer to different aspects of safety. BPA-free means the product does not contain bisphenol A, a chemical linked to health risks. Food grade, on the other hand, indicates that the material is safe for food contact under certain regulatory standards. A product can be food grade but not BPA-free, or vice versa. - Do all food containers in the U.S. have to be food grade?

Yes, if they are intended to come into direct contact with food. The FDA mandates that food contact materials must not adulterate the food or pose health risks. This includes packaging, storage containers, cooking utensils, and processing equipment. However, indirect materials (like external surfaces) may not be held to the same standards. - What common materials are not considered food grade?

Materials that can leach toxins, degrade easily, or react with food—such as PVC, recycled plastics with unknown content, non‑stainless steel metals, or industrial lubricants—are typically not food grade. Always verify the material’s origin, composition, and intended use before allowing food contact. - Is stainless steel always food grade?

Not necessarily. While stainless steel is widely used in kitchens, only specific grades like 304 (18/8) or 316 stainless steel are considered food grade due to their corrosion resistance and non-reactive properties. Lower grades may rust or leach metals into food, especially under high heat or acidic conditions.