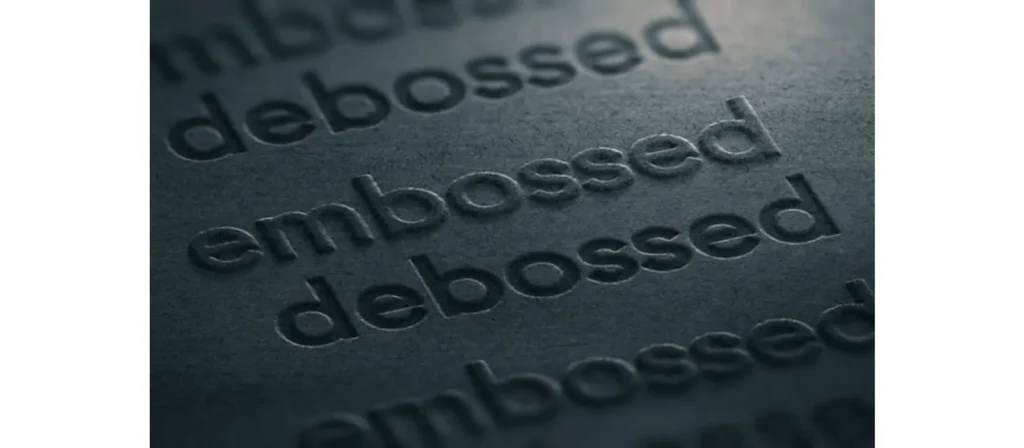

Embossing and debossing are printing techniques that create raised or recessed designs on a material’s surface to add texture, depth, and visual interest without using ink. Embossing raises the design above the surface, while debossing presses it into the material. Both methods are achieved by applying pressure with a custom-made metal die. They are widely used to enhance the look and feel of printed products such as packaging, business cards, book covers, and stationery, offering a subtle yet powerful way to elevate brand perception.

These techniques are especially effective when you want to signal quality, craftsmanship, or attention to detail. Unlike flat printing, embossing and debossing engage both the eyes and the hands, creating a sensory experience that is hard to ignore. Blind versions (with no ink or foil) offer understated elegance, while foil stamping adds color and shine. Their flexibility makes them a go-to choice across industries, from luxury retail to publishing and even food packaging.

In high-end retail, for example, a paper shopping bag with a debossed logo not only carries the product but quietly reinforces the brand’s premium image. Whether on a rigid gift box, a fine book cover, or a boutique coffee label, embossing and debossing turn everyday items into brand touchpoints that feel intentional and refined.

Differences between Blind Debossing and Embossing

What Is Embossing?

Embossing is a process that creates a raised design on the surface of a material by pushing it upward using a metal die set. The top layer of the material forms a three-dimensional shape that lifts off the flat surface. This is achieved by sandwiching the material between two dies: one with the design raised (called the male die) and one with the corresponding recessed shape (called the female die).

The result is a tactile and visible impression that adds physical height and dimension to a design. Embossing does not require any ink or pigment to be effective. When no color or foil is added, it is referred to as blind embossing. The visual effect comes mainly from the way light and shadow interact with the raised areas of the surface.

Embossing always adds volume by pushing outward from the back, creating a lifted effect that can be both seen and felt clearly.

What Is Debossing?

Debossing is the reverse of embossing. It creates a sunken or indented design by pressing a pattern into the surface of a material using a metal die. Rather than being raised, the design sits below the surface, forming a noticeable recess in the shape of the artwork.

This process typically uses a single die to press directly into the material without needing a second counter-die. Like embossing, debossing can be done without the use of ink or foil. This version is known as blind debossing. The shape is defined by its depth and the way shadows fall inside the recessed areas.

Debossing emphasizes the absence of surface rather than the addition of it. It creates a contour that gives the material a quiet, textured look through indentation.

Embossing vs. Debossing: Key Differences

| Feature | Embossing | Debossing |

|---|---|---|

| Design Effect | Adds dimension and prominence | Adds depth and subtlety |

| Tactile Feel | Elevated, convex texture | Recessed, concave texture |

| Common Uses | Logos, packaging, stationery | Book covers, leather goods, minimal branding |

| Durability | Slightly more prone to wear or flattening over time | Generally more durable and resistant to surface damage |

| Material Preference | Thicker, soft materials preferred | Works on soft and rigid materials |

| Visual Effect | Eye-catching and premium | Subtle, clean, and understated |

| Cost | Slightly higher with multi-level dies | Typically cost-effective for simple designs |

| Design Considerations | Bold shapes work best | Handles more detail if not too shallow |

This table outlines the essential differences between embossing and debossing. While both add depth and dimension to a design, they achieve it through opposite surface movements. Debossing often holds up better with repeated handling, while embossing can show more wear depending on the material and pressure used.

The Embossing and Debossing Process in Factory Machines

In a production environment, embossing and debossing are carried out using precision machinery that applies controlled heat and pressure to create either a raised or recessed design on various materials. The process begins with the creation of a custom metal die, which contains the artwork or logo that will be pressed into or onto the material.

The material, usually paperboard, leather, or plastic, is fed through a press machine where it is aligned between two parts: the male die and the female die. For embossing, the male die pushes upward. For debossing, it presses downward. In both cases, the material is firmly pressed between the dies, which may be heated depending on the desired finish.

Key Process Stages of Embossing and Debossing

- Die preparation. CNC-machined or hand-sculpted dies are made from brass, magnesium, or copper.

- Material setup. Sheets or rolls are loaded into the embossing press with guides to ensure accurate alignment.

- Pressing stage. Heat and pressure are applied to form the design, often within a few seconds.

- Quality check. Samples are pulled to verify alignment, depth, and consistency before starting full production.

This process can function independently or be integrated into larger packaging lines with foil stamping or offset printing units. Advanced machines allow for precise pressure control, varying levels of depth, and fast production speeds, making embossing scalable from small batches to full industrial runs.

4 Common Techniques in Embossing and Debossing

Blind Embossing / Debossing

Blind embossing or debossing creates a raised or recessed design without the use of ink, foil, or color. The impression relies solely on shape, light, and shadow for visibility, making it one of the most minimal and refined finishes in print design.

Because there’s no added contrast, clarity depends on strong, clean shapes that stand out through depth alone. It’s especially well-suited for simple logos, initials, or bold icons where texture speaks louder than color.

This technique is often chosen for its quiet elegance. It doesn’t draw attention with shine or pigment but leaves a lasting impression through feel and subtle form.

Foil Embossing / Debossing

Foil embossing or debossing combines the tactile depth of traditional embossing with the visual impact of foil application. This creates a design that is not only seen but also felt, making it ideal for high-end branding and presentation. Metallic foils such as gold, silver, and rose gold are commonly used, but options also include matte finishes, colored foils, and even holographic effects to match a variety of brand aesthetics.

The process typically involves placing a thin layer of foil between a heated die and the material. When heat and pressure are applied together, the foil fuses to the surface while the die shapes the raised or recessed design. The result is a glossy, eye-catching finish with dimensional texture.

While hot foil embossing is the most well-known approach, there is also a variation known as cold foil or UV printing, which uses a UV-curable adhesive and light instead of heat. In this method, the foil is applied inline during printing, offering faster production and better compatibility with heat-sensitive materials. Though cold foil does not allow for embossing in the same pass, it can be combined with embossing in a separate step for added effect.

This technique is especially effective for packaging, certificates, event invitations, and product labels that require both elegance and durability. The foil catches the light instantly, while the embossed or debossed texture invites touch, making the piece feel premium in every sense.

Photographic Embossing / Debossing

Photographic embossing, also known as sculptured embossing, is a high-detail technique that replicates the appearance of a photograph or illustration through multi-dimensional shaping. Instead of using a flat die, this method involves sculpting a die with varying depths to simulate highlights, shadows, and contours within the design.

The result is a detailed, lifelike impression that adds realism and depth. Unlike standard embossing that uses a single, consistent depth, photographic embossing introduces subtle gradations of height to bring out textures and facial features or intricate illustrations. This creates a visual effect that mimics the tonal range of a real image.

Due to the complexity of the die-making process, this technique often requires custom hand-engraving or 3D modeling and is more time-intensive than standard methods. It is best suited for projects where fine detail is essential, such as luxury packaging, collectible covers, special edition prints, or high-end certificates. The finished piece feels less like printed material and more like an embossed artwork.

Multi-Level Embossing / Debossing

Multi-level embossing or debossing uses a die with multiple depths or height variations to create a design with layered dimension. Unlike standard techniques that produce a single raised or recessed surface, this method allows different parts of the design to sit at different levels, giving the impression of depth, structure, and visual hierarchy.

This technique is ideal for complex designs such as logos with background and foreground elements, seals, or illustrations that benefit from added detail and texture. The varied elevation enhances both readability and tactile interest, making the design feel more dynamic and sculptural.

Creating a multi-level effect requires precise die manufacturing and careful design planning. Every layer must be considered in terms of depth and interaction with light and shadow. Although more technically demanding and often more costly, the final result offers a high-end, refined finish that sets printed materials apart in quality and presentation.

The Benefits of Embossing and Debossing

Embossing and debossing are not just decorative techniques. They serve real strategic purposes in design and branding. Beyond looking good, they shape how people interact with and remember your printed materials. These techniques engage more than just the eyes. They engage touch, perception, and even emotion. Below are the key benefits, along with one often-overlooked advantage that is worth noting.

Increased Visual Appeal

Adding raised or recessed texture instantly changes how a printed piece is perceived. Embossing and debossing introduce shadows, highlights, and depth that flat printing cannot replicate. These effects draw the eye to key elements such as a logo or brand name by making them stand out both visually and physically.

This added dimension brings a clear sense of polish and professionalism. Whether used blind or paired with foil, the result feels more intentional. A business card with an embossed logo or a box lid with a debossed monogram carries more weight in both appearance and impression than one that is just printed.

Sensory Experience

Touch is one of the most underutilized tools in branding, and embossing or debossing taps into it effectively. When someone picks up your brochure, package, or invitation and runs their fingers over a textured design, they immediately experience a richer, more memorable interaction. It is not just about what they see. It is about what they feel.

This tactile element can create a sense of luxury, authenticity, or intimacy depending on the design. In crowded markets, those physical cues can influence how your product is remembered. Sensory memory lasts longer, and a textured element on your packaging may be the subtle difference that keeps your brand top of mind.

Brand Differentiation

In a world filled with visual clutter, subtlety becomes a strength. Embossing and debossing help brands stand out without relying on loud colors or busy graphics. They signal intention, quality, and attention to detail, all traits that resonate with modern consumers.

This technique also opens creative branding possibilities. For example, using a blind debossed symbol as a recurring element across your product line builds recognition and cohesion. It is branding that does not feel like traditional branding, making it even more effective. When integrated thoughtfully, embossing or debossing can become part of a brand’s visual language.

Where Embossing and Debossing Can Be Used

Embossing and debossing are incredibly versatile techniques that can be applied across a wide range of products. Whether the goal is to enhance branding, elevate perceived value, or simply create a more tactile user experience, these finishes offer a subtle yet powerful design tool. Below are some of the most common and effective use cases where embossing and debossing truly shine.

Paper Plates

While often associated with disposable products, paper plates can benefit from debossed or embossed elements to enhance branding and create a more premium feel. Embossing can be used to imprint a logo or decorative pattern on the rim or center of a plate, making it stand out at events, catering gigs, or brand activations.

This is particularly effective for catered events, weddings, or branded experiences where visual consistency matters. The technique adds subtle design without affecting functionality and gives a plain surface more character with minimal cost.

Premium Retail Packaging

Retail packaging is one of the most common areas where embossing and debossing are used. A raised logo on a rigid box or a debossed texture across the surface can transform standard packaging into a high-end product experience. These tactile elements create a lasting first impression, often before the customer even opens the box.

In luxury markets especially, packaging is part of the product. Brands use texture not only to beautify but to signal value and craftsmanship. Whether applied to the lid, sides, or labels, these techniques enhance the perception of quality and care.

Food Packaging

Embossing and debossing are widely used in food packaging to elevate brand perception while maintaining a clean and functional design. For takeaway boxes, a debossed logo on kraft paper offers a minimal and eco-friendly look that communicates quality without relying on ink. Beverage cups, whether single wall, double wall or ripple wall, also benefit from tactile branding, as a raised or recessed logo can enhance both grip and visual appeal. Ripple wall cups in particular integrate embossing naturally into their surface texture, combining function with identity. Paper bags used for baked goods, takeaway meals or café items can feature subtle debossing to reinforce the brand in a way that feels premium yet understated. Together, these common packaging formats become effective tools for brand storytelling through texture and touch.

Book Covers and Luxury Publishing

Book covers have long been a canvas for embossing and debossing. From classic titles to modern coffee table books, textured elements can enhance the emotional impact of a book before a single page is read. Embossed titles, author names, or decorative flourishes are often used to draw attention and give a sense of permanence.

Luxury publishing, in particular, benefits from multi-level or photographic embossing, where fine detail adds depth to covers or inserts. These effects can also be found in limited editions, collector’s items, or special releases where presentation matters just as much as content.

Paper Bags and Branded Retail Packaging

Paper bags do more than carry purchases, they also carry your brand identity. A debossed logo or embossed emblem on a high-quality shopping bag adds a touch of refinement and turns everyday packaging into a reusable keepsake.

This approach is especially effective in boutique retail, cosmetics, or fashion. The tactile effect adds value, and when customers reuse the bag, it becomes an extension of your marketing. Embossing or debossing on paper bags doesn’t just look better, it subtly tells the customer: this brand pays attention to detail.

Considerations for Embossing and Debossing

While embossing and debossing add undeniable elegance and value to printed materials, they require careful planning to get right. These techniques are more than just pressing a design into paper. They involve mechanical processes, material choices, and design limitations that should be addressed early in your project.

First, material thickness matters. Thin or heavily coated paper may crack or warp under pressure, while thicker, softer stocks tend to hold impressions more cleanly. Always test your substrate before committing to full production, especially if you’re combining embossing with other finishes like foil.

Next comes design simplicity. Extremely fine lines, thin fonts, or detailed patterns can lose clarity once pressure is applied. For best results, use bold, clean shapes with adequate spacing. This ensures the impression is sharp and legible without unintended distortion.

Cost and production time are also key factors. Embossing and debossing require custom metal dies, and more complex executions like multi-level or sculpted effects will increase both lead time and price. This makes them less suited for low-volume, quick-turnaround jobs unless planned well in advance.

You should also consider registration accuracy, particularly when embossing aligns with printed or foiled elements. Even slight misalignments can reduce the visual impact. Work closely with your printer to ensure precise setup and alignment throughout the production process.

📊 Help Tip

When in doubt, request a sample or proof before full production. This helps catch potential issues with pressure, alignment, or material compatibility early on. Many experienced printers can also offer design feedback specific to embossing or debossing, which can save time, cost, and frustration later. Involving your production partner early is often the difference between a good impression and a great one.

FAQs

Conclusion

Embossing and debossing are more than surface-level design choices. They are tactile storytelling tools that bring dimension, texture, and emotion to printed materials. Whether you are working on luxury packaging, business stationery, or branded food containers, these techniques offer a quiet and powerful way to elevate your visual identity.

By understanding the differences between embossing and debossing, the available techniques, their practical applications, and the production considerations involved, you can make more informed design decisions that align with your brand’s goals. With the right planning and execution, even the simplest design can leave a lasting impression that is felt both visually and physically.