Paper food packaging is a type of material made from paper or paperboard that is safe for direct or indirect contact with food. In recent years, the global demand for sustainable and safe food packaging has grown dramatically. A report by Smithers Pira predicts the paper-based packaging market will surpass $370 billion by 2030, driven by environmental awareness and regulatory pressure. As plastic alternatives continue to rise, food-grade paper packaging has become a frontrunner in the race for eco-responsibility.

Yet, not all papers used in food packaging are created equal. Each type serves a distinct purpose, offering specific barrier properties, strength levels, and compatibility with wet, oily, or dry foods. Choosing the wrong material can result in soggy wraps, flavor contamination, or non-compliant packaging that jeopardizes your product’s marketability. This comprehensive guide breaks down the various types of paper for food packaging, helping you match the right material to your food product’s needs.

Kraft Paper

Kraft paper is a strong, durable paper made using the kraft pulping process, which involves chemically converting wood into pulp through the use of sodium hydroxide and sodium sulfide. This method preserves the long cellulose fibers, resulting in a material that offers superior tensile strength and tear resistance compared to traditional paper.

Available in natural brown or bleached white, kraft paper is valued for its raw appearance and eco-friendly profile, being fully biodegradable and recyclable without the need for plastic laminates or chemical coatings. Its breathability, moderate grease resistance, and structural integrity make kraft paper an ideal material for many food packaging applications.

Key Features

- High fiber strength: The long cellulose fibers from the kraft process provide superior tear resistance.

- Natural and eco-friendly: Fully recyclable, biodegradable, and often unbleached for minimal environmental impact.

- Excellent printability: Suitable for branding, labels, and food-safe inks without requiring surface coatings.

- Good stiffness and texture: Holds shape well and provides a natural, rustic appearance that enhances food presentation.

- Wide range of basis weights: Available from lightweight wrapping grades to heavy-duty bag grades for different packaging needs.

Common Applications

- Bakery bags and bread wraps

- Sandwich and burger sleeves

- Coffee cup sleeves and napkin bands

- Grocery bags and food carrier bags

- Tray liners and eco-friendly takeaway wraps

Flute Paper

Flute paper is a type of corrugating medium specifically engineered to form the wavy inner layer of corrugated board. It is produced from semi-chemical or recycled pulp through a high-temperature corrugation process, where the paper is pressed between heated rollers to create a wave-like structure. This “fluted” shape gives the final board its cushioning effect, compressive strength, and impact resistance.

The flute paper itself is not used as a standalone packaging material, but it plays a critical structural role in food-safe corrugated packaging. By varying flute sizes (such as E-flute, F-flute, or B-flute) manufacturers can control the thickness, stiffness, and crush resistance of the final packaging product, making it suitable for different food logistics needs.

Key Features

- High compression strength: The fluted shape provides excellent stacking and crush resistance

- Shock absorption: Protects food products during transport and handling

- Thermal insulation: The air pockets between flutes help maintain food temperature

- Lightweight structure: Offers durability without excessive weight

- Customizable flute profiles: Available in various grades like E-flute (thin and printable), B-flute (standard), or F-flute (microflute for compact packaging)

Common Applications

- Structural layer in corrugated pizza boxes and takeout containers

- Inner medium for beverage cup carriers and bakery trays

- Used in egg cartons, fruit crates, and sandwich boxes

- Flute layer in grease-resistant corrugated food trays

- Cold-chain food packaging requiring insulation and rigidity

SBS Paperboard(White Cardboard)

SBS paperboard, or Solid Bleached Sulfate paperboard, is a high-quality white paperboard made from bleached virgin wood pulp. It has a smooth, uniform surface that is ideal for high-end printing and food-grade packaging. Unlike recycled paperboard, SBS is free of contaminants and offers excellent visual appeal, strength, and cleanliness, making it suitable for direct food contact.

The board is often clay-coated on one or both sides to enhance printability and moisture resistance. It can also be laminated or coated with PE, PLA, or aqueous barriers to improve its grease and moisture barrier properties for food service applications. Because of its stiffness, purity, and premium appearance, SBS is commonly used for packaging frozen foods, bakery products, and high-end retail food boxes.

Key Features

- Pure white appearance: Produced from fully bleached virgin pulp, ideal for premium branding

- Excellent print surface: Supports vibrant, high-resolution printing and embossing

- High stiffness and rigidity: Maintains structure for boxes and folding cartons

- Food contact safe: Suitable for direct food packaging when uncoated or food-coated

- Customizable barrier options: Can be PE-coated, PLA-coated, or aqueous-coated for added protection

Common Applications

- Folding cartons for frozen food, baked goods, or chocolates

- Cake boxes, pastry boxes, and confectionery trays

- Lids and trays for takeaway food containers

- Inner liners or inserts in high-end retail food packaging

- Paper cups, food pails, and clamshells when laminated with PE or PLA

FBB Paperboard (Folding Box Board)

Folding Box Board (FBB) is a multi-layer paperboard made primarily from mechanical pulp sandwiched between outer layers of chemical pulp. The top layer is typically coated to enhance printing quality, while the back may be cream or white, depending on the grade. Known for its light weight, rigidity, and excellent print surface, FBB is a popular choice for high-quality folding cartons in the food industry.

Key Features

- Lightweight but stiff: Offers high strength-to-weight ratio, reducing material cost without compromising protection

- Coated printable surface: Excellent for high-resolution printing, ideal for retail and branding

- Multi-layer structure: Combines durability with flexibility for folding and creasing

- Versatile appearance: White front and optional white or cream back for visual flexibility

- Eco-friendly composition: Often made with renewable resources and widely recyclable

Common Applications

- Cereal boxes, snack packaging, and dry food cartons

- Folding cartons for tea, pasta, or baking mixes

- Custom-printed packaging for chocolate and confectionery products

- Pharmaceutical-style boxes for food supplements or nutrition bars

Cupstock Paper

Cupstock paper is a specialized grade of paperboard used as the base material for manufacturing disposable paper cups and containers. It is typically made from virgin wood pulp, offering a smooth surface, high stiffness, and strong wet strength to support hot or cold beverages. The base paper is not used directly but is usually coated with a barrier layer such as polyethylene (PE), polylactic acid (PLA), or aqueous coating to provide liquid resistance and heat sealing capability.

Cupstock is produced in large rolls or sheets and later printed, die-cut, and formed into cup bodies or lids. It is designed to perform well during converting processes like flexographic or offset printing, punching, and cup-forming. Depending on the coating, it may also be compostable or recyclable, making it a critical material in the shift toward more sustainable food packaging.

Key Features

- Excellent formability: Engineered for die-cutting, creasing, and cup-forming without cracking

- High wet strength: Maintains structural integrity with hot or cold liquids

- Barrier coating compatibility: Can be coated with PE, PLA, or water-based barriers for liquid resistance

- Food-grade purity: Made from virgin pulp, safe for direct contact with beverages

- Good print surface: Supports branding and product information with clean results

Common Applications

- Hot and cold drink cups (coffee, tea, juice)

- Paper cup sleeves and cup lids

- Ice cream cups and yogurt tubs

- Soup containers and takeaway bowls

- Paper-based milkshake and smoothie cups

Greaseproof Paper

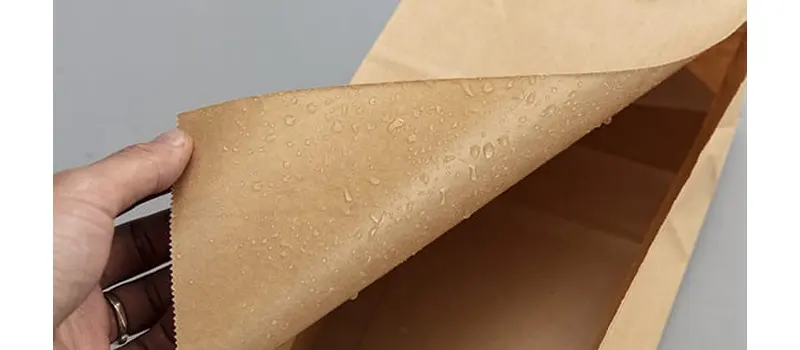

Greaseproof paper is a smooth, dense, and food-safe paper designed to resist the penetration of oils and fats. It is produced by refining the cellulose pulp through a process called supercalendering, which compresses the fibers tightly together and minimizes porosity. This results in a paper that forms a natural barrier against grease without the need for wax or plastic coatings.

Unlike waxed or laminated alternatives, greaseproof paper maintains its dry, matte surface while still effectively preventing oil seepage. It is commonly used in food packaging applications where direct contact with oily or moist foods is expected, and where appearance, hygiene, and ease of disposal are important considerations.

Key Features

- Natural grease resistance: Achieved through high fiber density rather than added coatings

- Clean surface finish: Prevents staining and maintains presentation quality

- Heat tolerance: Suitable for wrapping hot baked goods and fried snacks

- Food-safe and odorless: Free from chemical taste or smell migration

- Fully compostable and recyclable: Contains no plastic or synthetic additives

Common Applications

- Deli paper for cured meats, cheeses, and takeaway items

- Wrapping fried foods such as French fries, chicken wings, or spring rolls

- Lining trays and food baskets in fast-food or quick-service restaurants

- Wrapping baked goods like cookies, muffins, or pastries

- Inner wraps for burgers, sandwiches, and hot snacks

Butcher Paper

Butcher paper is a food-grade paper originally developed for wrapping raw meat, poultry, and seafood, but it has since expanded into a wide range of food packaging uses. Made from kraft pulp, butcher paper shares its roots with kraft paper, but it is specially processed to improve moisture resistance, breathability, and food safety compliance. It is typically available in white, pink, or natural brown, depending on its specific application and regional preferences.

While kraft paper may not always be food-safe, butcher paper is designed specifically for direct food contact. It is untreated or lightly treated to allow food to breathe while still offering protection from external contaminants. Its strength and clean appearance make it ideal for both raw and cooked food packaging.

Butcher paper is essentially a type of kraft paper that has been specially treated to meet the demands of wrapping fresh or cooked food products, particularly meats.

Key Features

- High wet strength: Holds up well when in contact with raw or moist foods

- Breathable and absorbent: Allows steam and moisture to escape while retaining structure

- Uncoated and food-safe: Contains no wax or plastic layers, ensuring safe direct food contact

- Multiple color options: Available in pink, white, or natural brown for different applications

- Tear-resistant and printable: Can be used with branding or product labels

Common Applications

- Wrapping raw meat, fish, or poultry in butcher shops and grocery stores

- Serving as a liner for food trays or meat counters

- Smoking brisket or ribs in BBQ operations using pink butcher paper

- Wrapping sandwiches or deli products for a rustic, natural presentation

- Lining display baskets or packaging fresh produce

Glassine Paper

Glassine paper is a smooth, glossy, and semi-transparent paper made by supercalendering bleached pulp to create a dense, uniform fiber structure. This process compresses the fibers to eliminate air pockets, resulting in a paper that is air-tight, grease-resistant, and resistant to moisture under moderate conditions. Unlike waxed or coated papers, glassine achieves its barrier properties without any added chemical treatments or surface coatings.

It is naturally pH neutral, lint-free, and recyclable, making it a preferred material for food-safe interleaving and inner wrapping. Its translucent appearance and elegant texture also make it suitable for premium product presentation, especially in the bakery, confectionery, and specialty food industries.

Key Features

- Grease and moisture resistance: Naturally repels oil and moisture without coatings

- Smooth and glossy finish: Enhances product presentation and tactile experience

- Translucent appearance: Allows partial visibility of the packaged item

- Non-absorbent and pH neutral: Safe for delicate or oily food surfaces

- Fully recyclable and biodegradable: Made from pure cellulose, free of plastic or wax

Common Applications

- Inner wrapping for baked goods, chocolates, and butter

- Interleaving paper between sliced cheese or deli meats

- Transparent liners for candy boxes or snack cartons

- Wrapping sticky or oily food items like nougat or toffee

- High-end food presentation in cafés, bakeries, or gift boxes

Plant Fiber Paper

Plant fiber paper is an eco-friendly packaging material made from non-wood renewable fibers such as bamboo, sugarcane bagasse, wheat straw, or other agricultural residues. It is designed to reduce reliance on traditional wood pulp and lower the environmental footprint of food packaging. Plant fiber paper offers a natural appearance and biodegradable properties, making it increasingly popular among brands pursuing sustainable packaging solutions.

This paper is typically molded or pressed into shape for trays, containers, or wraps, and can be coated for additional resistance to moisture and grease.

Key Features

- Made from renewable sources: Uses fast-growing plants and agro-waste instead of tree-based pulp

- Biodegradable and compostable: Breaks down naturally without leaving harmful residues

- Grease and water resistance: Can be treated or laminated to hold moist or oily foods

- Natural texture and color: Often unbleached, offering a rustic and organic look

- Lightweight but durable: Strong enough for takeout and ready-to-eat applications

Common Applications

- Fruit trays, salad containers

- Takeout lunch boxes for rice, noodles, or pasta

- Soup bowls and lids

- Beverage cup carriers

- Single-use food containers at events, markets, or festivals

Coated and Laminated Papers for Food Packaging

Coated and laminated papers are widely used in the food packaging industry. These papers are created by applying functional layers such as polyethylene (PE), polylactic acid (PLA), aluminum foil, or water-based coatings onto a paper substrate. This enhances the barrier properties of paper to meet various requirements like moisture resistance, grease resistance, heat sealability, and compostability.

Waxed Paper

Waxed paper is a food-safe paper that has been coated on one or both sides with a thin layer of wax (typically paraffin or soybean-based wax) to provide moisture resistance and moderate grease protection. The base paper is usually machine-glazed (MG) or supercalendered to ensure a smooth surface before waxing. The wax coating fills the paper’s pores, creating a flexible barrier that repels liquids and enhances pliability.

This type of paper is not heat-resistant like parchment paper but excels in cold or room-temperature applications where moisture control and visual appeal are important. Waxed paper has a slightly glossy finish and a soft texture, making it ideal for wrapping, separating, or displaying food items with a clean, premium look.

Key Features

- Moisture and grease resistance: Wax coating prevents seepage from moist or lightly oily foods

- Smooth and pliable: Easy to fold, wrap, or interleave without tearing

- Attractive appearance: Semi-gloss finish enhances food presentation

- Food-safe and odor-free: Coatings are safe for direct contact and do not affect taste

- Cost-effective: A budget-friendly option for large-scale food service or retail use

Common Applications

- Wrapping deli items such as cheese, cold cuts, or smoked fish

- Interleaving between slices of meat, burger patties, or baked goods

- Lining baskets, trays, and food service containers

- Wrapping candies, chocolates, and sticky confections

- Serving paper for sandwiches, pastries, or chilled desserts

Parchment Paper (Baking Paper)

Parchment paper, also known as baking paper in many regions, is a specially treated food-safe paper designed to be non-stick, grease-resistant, and heat-resistant. It is typically produced through an acid bath process (vegetable parchment) that gelatinizes the paper’s surface, reducing porosity and improving durability under heat. In commercial versions, the paper is often coated with a thin layer of food-grade silicone, further enhancing its non-stick and moisture-resistant properties.

Unlike waxed paper, parchment paper can withstand high oven temperatures without melting or smoking, making it ideal for both cooking and packaging applications. It is fully compostable (if uncoated or with compostable silicone) and provides a clean, professional appearance for both retail and food service environments.

Key Features

- Heat-resistant up to 230°C (445°F): Safe for use in ovens, microwaves, and food warmers

- Naturally non-stick: Prevents food from sticking to trays, pans, or other surfaces without added grease

- Moisture and grease resistance: Keeps food crisp by minimizing sogginess and preventing oil absorption

- Reusable and compostable: Especially when unbleached and free of silicone or coatings

- Clean and hygienic: Maintains a sanitary barrier between food and cooking surfaces, reducing cleanup needs

Common Applications

- Lining baking trays for cookies, pastries, or bread

- Wrapping baked goods or hot foods in takeout packaging

- Preventing sticking in cake tins, pizza pans, or muffin molds

- Steam cooking (e.g., en papillote fish or vegetables)

- Separating sticky or delicate items like nougat or dough portions

Freezer Paper

Freezer paper is a food-grade packaging material made from heavy-duty paper that has been coated on one side with polyethylene (PE) or another moisture-resistant layer. This coating provides a reliable barrier against water vapor and air, while the uncoated paper side remains writable, allowing for labeling or inventory tracking. The base paper is often made from strong bleached or natural kraft pulp to provide sufficient durability in cold storage environments.

Unlike waxed paper or parchment paper, freezer paper is specifically engineered for prolonged cold exposure. It helps prevent freezer burn by sealing in moisture and blocking oxygen penetration. It is commonly used in butcher shops, meat processing plants, and home kitchens for wrapping fresh cuts of meat, poultry, and fish before freezing.

Key Features

- Moisture and vapor barrier: Coated side prevents dehydration and freezer burn

- Writable paper surface: Allows notes, dates, or weight markings for inventory purposes

- Tear-resistant: Durable enough to withstand folding, stacking, and long-term freezing

- Food contact approved: Safe for direct contact with raw or cooked food

- Ideal for freezer environments: Performs reliably in low-temperature conditions over extended storage periods

Common Applications

- Wrapping meat, poultry, or fish for freezer storage

- Protecting bakery goods or pre-formed dough in frozen transport

- Lining freezer-safe trays and cartons

- Labeling and organizing food portions in cold-chain logistics

PE-Coated Paper (Polyethylene-Coated Paper)

PE-coated paper is a widely used packaging material where a thin layer of polyethylene is applied to the surface of paper. This coating provides excellent resistance to moisture, grease, and heat, making it ideal for applications such as cold drink cups, instant noodle bowls, and take-out food wraps. Its ability to be heat-sealed ensures secure closures for containers. However, the plastic layer complicates recycling and requires special facilities for separation.

PLA-Coated Paper (Compostable Coating Paper)

PLA-coated paper uses a bio-based polylactic acid layer derived from renewable resources like corn or sugarcane. Unlike PE, this coating is compostable under industrial conditions, offering an eco-friendlier alternative. It maintains good grease and moisture resistance, often used in biodegradable coffee cups, salad boxes, and compostable food trays. While not as heat-tolerant as PE, it appeals strongly to brands focusing on sustainability.

Laminated Paper for Food Packaging

This type of paper combines layers of paper with other materials such as plastic film, aluminum foil, or biodegradable film to create multi-layered laminates. It offers superior barrier protection against moisture, oxygen, and light, which helps extend shelf life. Commonly used for snacks, frozen food bags, and retort pouches, laminated paper can be customized based on packaging needs but is generally non-recyclable due to its mixed-material structure.

Grease-Resistant Coated Paper (Aqueous Barrier Paper)

This paper is treated with a water-based or wax-free coating that repels oil and light moisture without the use of plastic films. It’s commonly used for items like burger wraps, pastry bags, and sandwich sleeves. The coating is often FDA-approved for direct food contact and may be recyclable or compostable depending on its formulation, offering a functional yet sustainable alternative to plastic-lined papers.

Functional Barrier-Coated Paper (Water-Based or Bio-Based Coatings)

This is a broad category of advanced coated papers using customized water-based or bio-based barrier solutions. These coatings are engineered to provide targeted protection (e.g., water, oil, vapor) while maintaining recyclability or compostability. They are versatile and can be tailored for both dry and moist food products, used in items like bakery liners, food sachets, and sustainable takeaway packaging.

Trends and Innovations in Paper Food Packaging

The paper food packaging sector is evolving rapidly as sustainability expectations and regulatory pressure accelerate material innovation. Paper is increasingly favored as a recyclable, plastic-free solution, supported by new barrier technologies and responsible sourcing standards.

1. Regulatory Pressure Accelerating Material Transformation

Global regulations are speeding up the transition toward safer and more sustainable paper packaging. Key frameworks such as EU Regulation 1935/2004, EU Single-Use Plastics Directive, US FDA 21 CFR food-contact standards, and China’s GB 4806 food-contact material standards are pushing the industry to adopt PFAS-free, recyclable and mono-material paper solutions. As a result, manufacturers are prioritizing compliant barrier coatings, cleaner fiber sources and paper structures that can meet both environmental and food-safety requirements.

2. Rapid Innovation in Barrier and Functional Coatings

Paper is increasingly expected to perform like plastic while remaining environmentally friendly. This drives innovation in barrier technologies that provide moisture, grease, oxygen and aroma protection without relying on traditional films or PFAS-based chemicals.

Typical examples include:

- high-barrier grease-resistant papers

- water-based barrier coated papers

- fluoro-free oil-resistant papers

- microwave-safe and oven-safe papers

- oxygen-barrier and aroma-barrier papers

- heat-seal specialty base papers

These specialty papers enable paper packaging to enter new applications previously dominated by plastic or foil structures.

3. Growth in Alternative and Plant-Based Fibers

With the bio-economy expanding, manufacturers are exploring non-wood fibers such as bagasse, bamboo and wheat straw. These fibers reduce dependence on virgin wood pulp and offer a strong sustainability story for food brands looking to differentiate through environmental performance.

4. Upgraded Premium Paperboards for Branding and Shelf Impact

Food and beverage companies increasingly rely on high-quality SBS and FBB paperboards to achieve stronger branding, better print performance and improved structural integrity. Smooth surfaces, enhanced whiteness and advanced coating treatments support premium bakery, chocolate, dessert and retail-ready applications.

5. Performance-Driven Design for Food Delivery and E-Commerce

The rise of takeaway, meal kits and e-commerce grocery delivery has increased demand for stronger, more durable paper packaging. Papers with improved stiffness, wet strength, condensation control and leak resistance are becoming essential for modern foodservice and delivery models.

How to Choose Types of Paper for Food Packaging?

Selecting the right paper food packaging requires striking a balance between food safety, functional performance, and sustainability. Different paper types offer different levels of strength, barrier protection, and environmental benefits, so choosing the correct material depends on the specific requirements of the food product and its supply chain.

- Food Characteristics: Assess whether the food is oily, moist, dry, frozen, or baked, as each requires different barrier properties.

- Required Performance: Identify the required resistance levels, such as grease-proofing, moisture resistance, heat tolerance, or oxygen/aroma barriers.

- Packaging Format: Different formats require different papers. Wraps, cups, cartons, trays, and molded fiber products each have their ideal material match.

- Sustainability Requirements: Consider plastic-free, PFAS-free, recyclable, or compostable options based on market expectations and brand goals.

- Regulatory Compliance: Ensure materials meet FDA, EU 1935/2004, GB 4806, or local food-contact regulations.

- Cost vs. Functionality: Choose materials that meet the necessary performance requirements without over-specification or unnecessary coatings.

FAQs

Which paper is used for food packaging?

Several types of paper are used for food packaging, each serving different purposes. Common options include kraft paper, greaseproof paper, parchment or baking paper, waxed paper, glassine paper, cupstock paper, and SBS or FBB paperboard. Specialty barrier papers and coated papers are also used when additional grease, moisture or heat resistance is required.

What is the difference between baking paper and food wrapping paper?

Baking paper (parchment or silicone-coated paper) is heat-resistant and non-stick, designed for oven use and baking applications. Food wrapping paper, such as kraft, greaseproof or waxed paper, is used for wrapping and serving food but is not designed for high-heat baking. Wrapping papers focus on grease resistance, strength or moisture control rather than oven performance.

What is food safe paper?

Food safe paper is paper that meets regulatory standards for direct food contact, such as FDA, EU 1935/2004 or GB 4806. It is manufactured without harmful chemicals and is tested to ensure it does not transfer substances to food. Examples include food-grade kraft, greaseproof paper, baking paper, cupstock, SBS board and certified specialty barrier papers.

What is the difference between SBS and FBB paperboard?

SBS (Solid Bleached Sulfate) is a premium whiteboard made from virgin pulp, offering excellent whiteness and printability. FBB (Folding Box Board) has a multi-layer structure and provides higher stiffness with a slightly more natural surface. Both are widely used for cartons and food boxes.

Are coated papers recyclable?

PE-coated papers and laminated structures can be more difficult to recycle, depending on local systems. However, water-based, plastic-free and mono-material coated papers are increasingly designed for easier recycling.

Conclusion

Choosing the right type of food packaging paper ultimately depends on the characteristics of the food, required barrier performance, sustainability targets and local regulatory requirements. With continuous innovation in bio-based coatings, PFAS-free barrier technologies and alternative plant fibers, the industry is moving quickly toward safer, more efficient and more environmentally responsible solutions.

For businesses and food brands, understanding the strengths of each paper type enables smarter material selection and more future-ready packaging strategies. As paper technology evolves, it will continue to play a central role in shaping the next generation of sustainable food packaging.

Over the years, Million Pack has focused on developing food packaging that is reliable, practical, and aligned with the industry’s move toward greener materials. Our goal is to ensure that every item we produce supports both the businesses that serve food and the customers who enjoy it. By combining responsible materials with thoughtful design, Million Pack works to create packaging that protects food, strengthens brand trust, and contributes to a more sustainable future.